In the world of manufacturing and automation, efficiency and precision are more critical than ever. One indispensable tool making waves across industries—especially in the coil winding sector—is the automatic wire stripper. As we navigate through 2025, these machines are not just convenient tools but vital assets that significantly enhance operational productivity, accuracy, and safety. The benefits of automatic wire strippers combined with the rise of smart manufacturing and high-mix, low-volume production environments, has made them a necessity for manufacturers to prepare for 2025 and the next decade of manufacturing advancements.

For companies like Itasca Automation Systems, which specialize in precision-engineered coil winding equipment, the automatic wire stripper complements a broader mission: providing manufacturers with innovative, cost-effective automation solutions that meet the unique demands of the industry.

The Growing Complexity of Wire Processing in 2025

Precision Matters More Than Ever

Modern electronic components are shrinking, while performance expectations continue to rise. This means tighter tolerances, more complex terminations, and extremely fine wires, sometimes as small as 38 to 44 AWG. Manual stripping methods simply do not meet the task of consistent performance at this level.

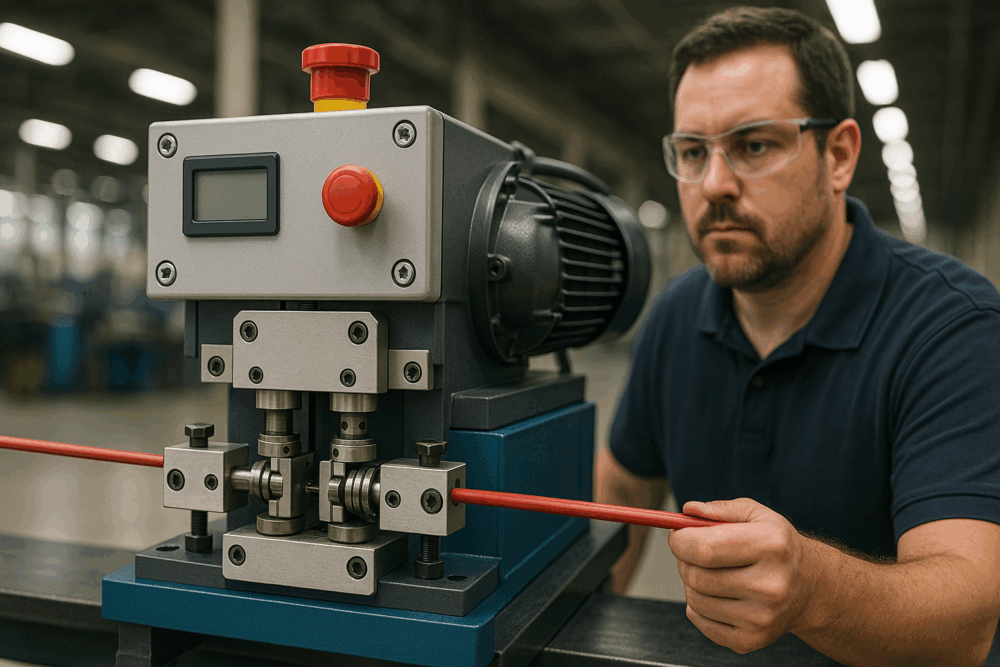

Automatic wire strippers provide precision down to the micron, ensuring repeatable results regardless of operator skill. They can handle a variety of insulation types—thermoplastic, enamel, silicone, PTFE—and adapt quickly to different wire gauges and profiles. This precision is especially critical in coil winding, where even minor damage to conductor surfaces can impact electrical performance.

High-Mix, Low-Volume Production Trends

One of the dominant trends in 2025 is the move toward flexible manufacturing systems. Clients demand shorter lead times and more product variants, which places a premium on setups that minimize downtime and manual retooling. Automatic wire strippers equipped with programmable logic controllers (PLCs) and intuitive human-machine interfaces (HMIs) can switch between wire types and stripping configurations in seconds.

Whether you’re preparing leads for multi-spindle winding or soldering terminations, automatic strippers offer unmatched versatility, fitting seamlessly into both stand-alone stations and integrated coil finishing lines.

The Economic Case for Automatic Wire Strippers

Labor Cost Savings

Skilled labor is becoming increasingly scarce and expensive. Training operators to strip and prep wires manually is both time-consuming and inconsistent. Automatic wire strippers:

- Eliminate operator variability

- Require minimal training

- Reduce rework and scrap

In most cases, the return on investment (ROI) can be realized in a matter of months, not years.

Reduced Material Waste

When stripping manually, it’s common to encounter:

- Over-stripped wires that damage the conductor

- Undersized strips that cause poor connections

- Frequent wire breaks

Automatic wire strippers minimize these issues with programmable accuracy and real-time error detection. The result is reduced material waste, better product quality, and higher customer satisfaction.

Integration with Smart Manufacturing Systems

Industry 4.0 Compatibility

Today’s wire stripping systems are designed with Industry 4.0 integration in mind. They can communicate with upstream and downstream equipment using Ethernet/IP, OPC UA, or MQTT protocols. This allows them to:

- Log performance data

- Perform predictive maintenance

- Adjust settings automatically based on work order data

By integrating wire strippers into a broader automation platform, manufacturers gain real-time visibility into productivity, traceability, and machine status.

Seamless Workflow Automation

For coil winding processes involving soldering, terminal insertion, and testing, automatic wire strippers ensure perfectly prepared wire leads, reducing failure points in solder joints or crimped terminals. This enables a smoother, faster transition between workstations and reduces downtime due to manual prep errors.

At Itasca Automation Systems, we’ve seen firsthand how automatic wire stripping technology contributes to the lean, modular design philosophy of our machines—reducing setup times and increasing throughput.

Enhancing Workplace Safety and Ergonomics

Manual stripping tools often require repetitive hand motions that lead to fatigue, strain injuries, and inconsistent performance. Automatic systems:

- Eliminate repetitive stress injuries

- Reduce the risk of accidents from knives or blades

- Promote better posture and operator comfort

Especially in high-volume environments, this translates to fewer workplace injuries and higher morale—two often-overlooked but essential components of sustainable manufacturing.

Key Features to Look for in 2025’s Automatic Wire Strippers

AI-Powered Optimization

Some newer models are equipped with AI algorithms that learn optimal stripping parameters based on wire type, diameter, and insulation. These smart systems can flag inconsistencies and recommend adjustments, ensuring error-free operation across long production runs.

Touchscreen Interfaces and Digital Memory

Operators can now use intuitive touchscreen interfaces to:

- Select wire profiles

- Load pre-configured programs

- Run diagnostics or calibrations

Digital memory allows for instant switching between jobs, which is essential in custom or short-batch production.

Modular Design for Easy Maintenance

Much like Itasca’s own approach to modular machine design, many automatic wire strippers feature plug-and-play modules for blade replacements, sensors, and feeding systems. This minimizes downtime and lowers maintenance costs, making them a perfect match for lean manufacturing strategies.

Industry Use Cases: How Automatic Wire Strippers Are Changing the Game

Automotive Coil Manufacturing

In the automotive sector, especially for electric vehicles (EVs), the demand for high-quality, precisely wound coils has never been higher. Automatic wire strippers:

- Ensure compliance with OEM standards

- Minimize defects in ignition and stator coils

- Integrate smoothly into robotic handling systems

Aerospace and Defense

These sectors demand the highest level of traceability and reliability. Automatic wire strippers provide barcoded tracking of each operation, along with precision that ensures MIL-spec compliance. For mission-critical coil components, this reliability is indispensable.

Medical Devices

Coils used in medical imaging or minimally invasive tools must meet strict biocompatibility and electrical specs. Automatic stripping ensures no contamination or damage, reducing risk in life-critical applications.

The Itasca Advantage in Precision Coil Automation

At Itasca Automation Systems, we understand the unique demands of the coil winding industry. Our engineers combine deep industry expertise with the latest in 3D CAD modeling and modular design principles to deliver customized, end-to-end automation solutions.

Our machines routinely incorporate automatic wire stripping as part of a broader finishing process, including:

- Multi-spindle winding

- Terminal insertion

- Precision soldering

- Insulation taping

- In-line electrical testing

We know that automation is not one-size-fits-all. That’s why we work closely with each customer to design systems that adapt to their specific coil configurations, production volumes, and regulatory environments. We also have inline wire strippers ready for purchase. Or, we can build you a custom production line with automatic wire stripping machines. Contact us today for more information.

Looking Ahead: Automation for the Next Decade

As manufacturing enters its next phase—marked by tighter margins, complex products, and heightened demand for traceability—the role of the automatic wire stripper will only grow. These machines are no longer optional. They are foundational tools that allow coil winding manufacturers to meet 21st-century demands head-on.

Investing in automation isn’t just about boosting production—it’s about future-proofing your business. Automatic wire strippers represent a critical link in the automation chain, enabling smooth, efficient, and high-quality wire preparation that powers the entire manufacturing lifecycle.

Don’t Get Left Behind

The question isn’t whether you need an automatic wire stripper in 2025—it’s whether your business can afford to operate without one. From labor savings and error reduction to advanced integrations and safety improvements, the benefits are too significant to ignore.

At Itasca Automation Systems, we don’t just provide machines—we engineer solutions tailored to your exact requirements. If you’re ready to elevate your coil winding processes with the latest in automation, we invite you to connect with our team.

Contact us to learn how we can help you integrate automatic wire stripping into your manufacturing systems and achieve the precision, efficiency, and reliability your customers demand.

Let’s build the future of coil automation—together.

Comments are closed