The coil winding industry is witnessing a transformative wave of innovation spurred by the relentless drive for greater productivity, precision, and customization. As manufacturers seek solutions that can deliver both speed and accuracy while minimizing waste and downtime, the development of advanced coil winding equipment has taken center stage.

The Role of Coil Winding in Modern Manufacturing

Coil winding is at the heart of countless electronic and electromechanical applications—from transformers and inductors to motors, sensors, and solenoids. The precision and consistency with which coils are wound directly impact the performance, efficiency, and reliability of the end product. Given the critical role these components play in sectors like automotive, medical, telecommunications, and renewable energy, enhancing coil winding efficiency translates to a competitive advantage across industries.

The Evolution of Coil Winding Equipment

Traditional coil winding machines were largely mechanical, manually operated, and limited in flexibility. However, advances in control systems, sensor integration, and automation have drastically redefined what modern coil winding machines can achieve. The leap from mechanical to mechatronic systems—where mechanical components are integrated with electronic controls—has ushered in a new era of intelligent, adaptive, and high-throughput winding solutions.

Key Innovations Driving Efficiency

Let’s explore the most impactful innovations that are redefining coil winding efficiency.

1. Multi-Spindle Automation

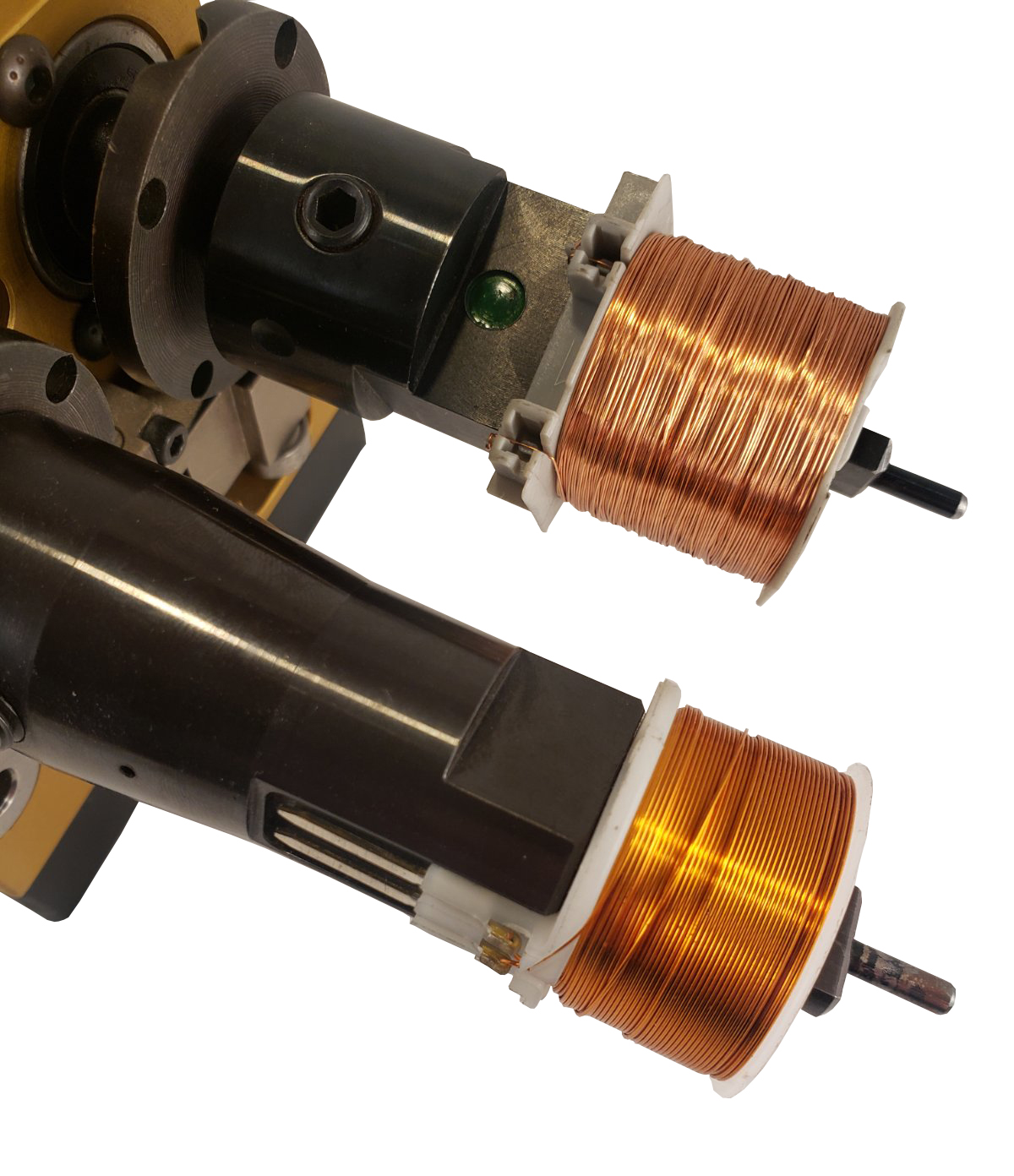

One of the most powerful advancements in coil winding equipment is the advent of automated multi-spindle winding systems. These machines allow simultaneous winding of multiple coils, drastically reducing cycle times and increasing throughput.

Modern multi-spindle machines are designed to handle variations in coil size, shape, and winding configuration without sacrificing precision. By utilizing synchronized motors and programmable logic controllers (PLCs), these systems ensure consistent tension, pitch, and layering across all spindles.

2. Lean Modular Machine Design

Gone are the days of one-size-fits-all machines. Today, lean modular designs enable manufacturers to configure their equipment to meet exact process requirements. This modularity allows for:

- Faster machine builds and customizations.

- Simplified maintenance and upgrades.

- Flexible retooling for different products.

At Itasca Automation Systems, for example, our lean modular approach allows us to tailor machines that align precisely with each client’s production and design needs.

3. Advanced CAD and Simulation Integration

The use of 3D CAD tools and digital twin simulations during the design phase enables engineers to visualize, test, and optimize coil winding machinery before a single part is fabricated. This concurrent engineering process reduces lead times, identifies potential issues early, and ensures a smooth transition from design to production.

Moreover, simulation tools allow for stress analysis, motion simulation, and thermal modeling, ensuring that machines will perform under real-world conditions.

4. Integrated Finishing Operations

Efficiency doesn’t stop at the winding process. Today’s high-performance coil winding equipment includes integrated finishing stations for operations such as:

- Terminal insertion

- Soldering

- Taping

- Electrical testing

- Labeling and packaging

Integrating these steps into a single production cell eliminates the need for manual transfers and reduces production times while enhancing quality control.

5. Real-Time Monitoring and Smart Feedback Systems

Industry 4.0 technologies are now commonplace in coil winding equipment. Machines equipped with sensors and real-time monitoring systems can track parameters such as:

- Winding tension

- Spindle speed

- Coil dimensions

- Environmental conditions

These systems provide instant feedback, triggering alerts or automatic adjustments to maintain quality and prevent waste. The resulting predictive maintenance capabilities also extend machine life and reduce unexpected downtime.

6. Servo-Driven Precision Control

Servo motors have replaced stepper or AC motors in many high-performance winding machines due to their unparalleled accuracy, torque control, and speed range. These motors allow for:

- Micro-adjustments in winding position

- Fast start/stop operations

- Smooth layering and pitch consistency

This level of control is particularly vital for high-frequency applications, where even minute winding inconsistencies can compromise functionality.

7. Custom Software Interfaces

Custom-developed HMI (Human Machine Interface) software now plays a central role in operational efficiency. Operators can quickly adjust parameters, monitor performance metrics, and upload recipes for different coil types—all from an intuitive touchscreen.

At Itasca Automation Systems, our solutions often include tailored control interfaces that simplify complex processes and reduce operator error.

Industry Applications and Efficiency Gains

Automotive Sector

With the rise of electric vehicles (EVs), the demand for precision-wound coils in motors, sensors, and inductors has skyrocketed. Automated systems capable of producing high volumes of reliable windings are essential to keep up with production schedules.

Medical Devices

Repeatability and quality control are non-negotiable for medical applications. Innovations like real-time defect detection and automatic rejection systems help maintain the industry’s stringent standards.

Telecommunications and IoT

Miniaturized coils for wireless communication devices and IoT sensors require ultra-fine wire winding with exacting tolerances. Advanced servo-driven systems and microscopic visual inspections have made it possible to meet these needs at scale.

Environmental and Cost Benefits

Modern coil winding equipment isn’t just more efficient—it’s more sustainable. Features such as optimized wire pathing, reduced scrap generation, and energy-efficient motors contribute to greener operations. Additionally, these innovations often lead to:

- Lower operating costs due to reduced waste and faster production cycles.

- Reduced training time thanks to intuitive software and user-friendly interfaces.

- Fewer rejected parts, improving overall yield and profitability.

The Itasca Automation Systems Advantage

At Itasca Automation Systems, we are committed to pioneering the next generation of coil winding machinery. Our engineers bring decades of experience and a collaborative spirit to every project. By embracing modern 3D CAD technologies, lean modular designs, and concurrent engineering practices, we ensure that each machine we deliver is optimized for the customer’s unique requirements.

Our equipment lineup includes:

- Automated Multi-Spindle Winders – High-volume, high-precision machines for simultaneous coil production.

- Terminal Insertion Modules – Automated systems for adding terminals to coil assemblies with speed and accuracy.

- Soldering and Taping Solutions – Integrative processes for coil finishing that enhance durability and reliability.

- Testing Systems – Comprehensive quality assurance tools to ensure each coil meets strict standards.

Our state-of-the-art facility, located in Door County, Wisconsin—an area renowned for its craftsmanship and innovation—reflects our commitment to quality, community, and continuous improvement. We are proud to draw inspiration from Door County’s rich heritage in shipbuilding and agriculture as we push the boundaries of coil winding technology.

Final Thoughts: Preparing for the Future

As demand grows for miniaturized electronics, electric vehicles, and smart devices, the pressure on manufacturers to deliver precision coils quickly and affordably continues to rise. Investing in modern coil winding equipment is no longer a luxury—it’s a necessity.

Efficiency gains made possible by automated multi-spindle systems, real-time monitoring, lean modular designs, and integrated finishing stations are transforming the way coils are produced. These advancements not only meet today’s manufacturing demands but also position businesses to adapt and thrive in the future.

Let’s Build the Future of Coil Winding Together

If you’re seeking innovative, reliable, and cost-effective solutions for your coil winding needs, Itasca Automation Systems is here to help. Whether you’re modernizing your existing production line or launching a new product, our team will work closely with you to design and deliver machinery that meets your exact specifications.

Don’t settle for off-the-shelf solutions—partner with a team that brings expertise, creativity, and a commitment to excellence. Contact us directly to discuss how we can help you take your coil winding operations to the next level.

Your challenge is our opportunity—let’s engineer success together.

Comments are closed