In the competitive world of modern manufacturing, the race for productivity and precision is relentless. Nowhere is this truer than in coil winding and related finishing processes, where accuracy, repeatability, and throughput define profitability. For many manufacturers, the critical question isn’t whether to automate, it’s how. Should you invest in a fully automated conveyor-based system, or will a stand-alone station strategy deliver better returns? When evaluating the right solution for your operation, it’s essential to look beyond the price tag and focus on long-term return on investment (ROI). For facilities producing inductors, transformers, and other coil-based components, an automated coil winding line can represent the most significant leap forward in performance, efficiency, and consistency.

The Core of the Decision: Automation Strategy and ROI

Automation has evolved far beyond simple labor replacement. Today’s automated systems are intelligent, flexible, and interconnected, capable of transforming the way manufacturers think about production flow. But the ROI of an automation investment depends heavily on how the system is implemented.

Stand-alone stations often appeal to manufacturers seeking flexibility, modularity, or lower initial costs. Each station performs a specific task, such as winding, soldering, taping, or testing, and may be operated manually or semi-automatically. These systems can be easily added or modified as production needs change.

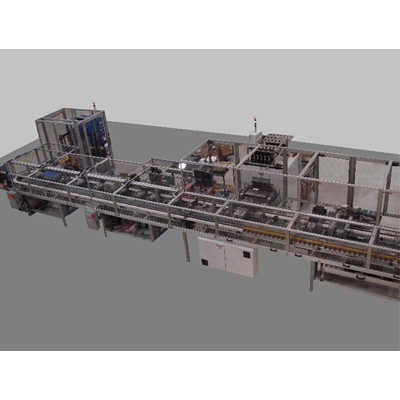

Automated conveyor lines, on the other hand, integrate multiple processes into a continuous, coordinated flow. Components move automatically from one operation to the next, minimizing human intervention, maximizing throughput, and reducing variability. While this approach requires higher upfront investment, the long-term gains in efficiency and cost savings often dwarf those of independent workstations.

Initial Cost vs. Long-Term Gain

The most common reason manufacturers choose stand-alone stations is cost. The initial price of a conveyor line can be two to three times higher than the cost of individual semi-automated machines. However, ROI calculations must account for more than the purchase price.

Stand-alone stations typically require operators at each step, increasing labor costs and introducing variability between parts. Even with automation in individual stations, manual loading, unloading, and material handling can create production bottlenecks.

By contrast, an automated conveyor line eliminates much of that human dependency. It maintains a consistent pace, optimizes cycle time, and drastically reduces downtime between processes. When analyzed over a five- to ten-year horizon, the total cost of ownership often tilts decisively in favor of full automation. Savings in labor, scrap, rework, and maintenance accumulate rapidly.

For example, consider a mid-volume manufacturer of electromagnetic coils producing 200,000 parts annually. Transitioning from semi-automated stand-alone machines to an automated conveyor line might cut labor requirements by 40% and improve first-pass yield by 15%. At that scale, the annual cost savings can exceed six figures, quickly offsetting the higher initial capital expenditure.

Space Utilization and Facility Efficiency

Physical footprint is another crucial consideration. Stand-alone stations require separate work areas, often arranged in islands or clusters. Material must be transported manually between stations, adding clutter and inefficiency to the production floor.

Conveyor-based automation consolidates these operations into a single, streamlined flow. Material travels automatically, minimizing floor congestion and reducing the need for staging areas. The result is not just a smaller footprint per part produced but also a safer and more organized work environment.

In industries like coil winding, where precision and cleanliness matter, maintaining a controlled production environment is vital. Automated conveyor systems support better process discipline and reduce contamination risks, ensuring consistent part quality.

Throughput, Consistency, and Quality Control

In manufacturing, throughput is king. Every second saved per cycle translates into tangible cost savings. Stand-alone systems are inherently limited by the speed and attention span of human operators. A single slow or inattentive operator can create a ripple effect of delays.

Conveyor lines, however, move at a fixed, optimized pace. Operations are synchronized so that each process feeds seamlessly into the next. Downtime is minimized, and the system’s rhythm keeps production consistent from the first shift to the last.

Beyond speed, consistency is one of the most valuable benefits of full automation. In coil winding and related processes like terminal insertion, soldering, or testing, even minor variations can lead to costly rework or field failures. Automated conveyor lines eliminate human inconsistency, delivering uniform tension, placement, and termination quality every time.

Advanced control systems and data collection tools further enhance this advantage. Sensors and vision systems monitor every step, automatically flagging anomalies and ensuring that only in-spec parts move forward. This not only boosts quality but also provides traceability, critical for industries such as automotive, aerospace, and medical devices.

Labor and Skill Requirements

Labor considerations often drive automation decisions. While stand-alone stations require multiple operators, they also offer a gentler learning curve. Training employees to run a single process is straightforward, making staffing more flexible.

In contrast, automated conveyor lines demand a different skill set. Fewer operators are needed, but those who remain must be capable of managing a complex, interconnected system. Maintenance personnel must understand robotics, sensors, and control software.

For many manufacturers, this shift can be a positive one. It reduces dependency on repetitive manual labor and fosters a more skilled, technical workforce. When paired with effective training programs, automation can transform your shop floor into a hub of precision and continuous improvement.

Scalability and Flexibility

Flexibility is often cited as a key advantage of stand-alone systems. Because each station is independent, manufacturers can easily reconfigure layouts, adjust workflows, or upgrade individual processes as product designs evolve. This modularity can be particularly appealing for job shops or R&D environments, producing a wide range of coil geometries or custom prototypes.

Automated conveyor lines, by contrast, are designed for consistent, repeatable production. Once optimized, they excel at high-volume or long-run manufacturing. However, this doesn’t mean they’re rigid. Modern conveyor systems, such as those engineered by Itasca Automation Systems, use modular design principles that allow reconfiguration without full system replacement. Quick-change tooling, programmable motion control, and flexible software logic all enable product variation within a single line.

In other words, today’s automated coil winding lines are no longer the “one-product-only” systems of decades past. They can pivot between product families with minimal downtime, supporting both efficiency and adaptability.

Maintenance, Reliability, and Uptime

Every minute of downtime erodes ROI. Maintenance requirements and reliability are, therefore, critical considerations when comparing automation strategies.

Stand-alone stations tend to have simpler mechanics, but their reliance on manual handling increases wear on fixtures, connectors, and tooling. In addition, because each station operates independently, maintenance schedules can become fragmented, and one machine may be down while others sit idle waiting for parts.

An automated conveyor line centralizes maintenance and monitoring. Predictive maintenance algorithms and sensors track performance data in real time, allowing technicians to anticipate issues before they cause failure. Centralized lubrication, diagnostics, and control systems reduce maintenance effort and extend equipment life.

Moreover, automation suppliers design with reliability in mind. Using lean, modular architectures and precision components, they create machines built for continuous operation in demanding environments. This results in higher uptime, better part quality, and more predictable production schedules.

Data, Analytics, and Industry 4.0 Integration

One of the less obvious but increasingly vital ROI drivers in automation is data. In today’s Industry 4.0 ecosystem, machines are no longer isolated; they’re connected.

Automated conveyor lines can generate and collect data from every operation, offering deep visibility into production metrics such as cycle time, yield, and machine utilization. This information enables continuous improvement and faster troubleshooting. Real-time dashboards allow managers to identify bottlenecks instantly and make data-driven decisions.

Stand-alone stations, especially older models, typically lack this integration. While some may have local displays or limited data capture, the absence of centralized connectivity makes plant-wide optimization difficult.

When comparing long-term ROI, the difference is substantial. The ability to measure and improve performance across an entire line is one of the key enablers of sustainable productivity growth, and one of the strongest arguments for investing in a connected, automated solution.

Safety and Ergonomics

Safety is another area where conveyor-based automation provides significant advantages. Manual material handling is one of the most common causes of workplace injuries. By automating part transfer between stations, conveyor systems reduce operator fatigue and repetitive motion hazards.

In addition, automated lines minimize exposure to hot soldering tools, rotating spindles, and other potentially hazardous equipment. Sensors and interlocks ensure that the system cannot operate unless all guards are in place, protecting workers while maintaining uptime.

Stand-alone systems can also be designed with safety in mind, but the reliance on human intervention inherently increases risk. From an ROI perspective, fewer injuries translate to lower workers’ compensation costs, less downtime, and improved employee morale.

Customization and Specialized Processes

One of the strengths of Itasca Automation Systems lies in its ability to design machines specifically tailored to each customer’s process. Whether you’re producing micro-coils for sensors or large transformer windings, every detail, from spindle configuration to soldering parameters, can be optimized for performance and cost efficiency.

For manufacturers considering automation, this level of customization can make all the difference. A properly engineered automated coil winding line is not a one-size-fits-all solution; it’s a precision-built system designed around your product’s geometry, tolerances, and production goals.

Stand-alone stations may be easier to source off the shelf, but they rarely deliver the same process optimization. Integrating disparate machines from multiple suppliers often leads to communication mismatches, inconsistent part flow, and higher maintenance complexity.

Environmental and Community Impact

Automation isn’t just about economics; it’s also about sustainability and community. By reducing scrap, improving energy efficiency, and optimizing process flow, automated conveyor lines contribute to a smaller environmental footprint.

At Itasca Automation Systems, this philosophy aligns with a broader mission: to deliver innovative, collaborative, and cost-effective solutions that benefit customers, employees, and the Door County community. Door County, Wisconsin, with its proud heritage of craftsmanship and shipbuilding, provides the perfect backdrop for precision engineering. Every Itasca system reflects this tradition of excellence, combining advanced technology with Midwestern integrity.

Making the Right Choice for Your Operation

Ultimately, the decision between stand-alone stations and an automated conveyor line depends on your production goals, product complexity, and business strategy.

- If you produce small batches or highly variable product types, stand-alone systems may provide the flexibility you need.

- If your operation depends on consistent, high-volume output, a conveyor-based automation line will almost always deliver superior ROI.

The ideal path for many manufacturers lies somewhere in between, a hybrid approach that combines the flexibility of modular stations with the efficiency of automated material handling. Working with an experienced engineering partner can help you identify that balance and design a system tailored to your exact needs.

Why Partner with Itasca Automation Systems?

For decades, Itasca Automation Systems has been a trusted name in precision machine design for the coil winding industry. Our team of engineers brings extensive experience in designing, building, and integrating automated multi-spindle winders, terminal insertion machines, soldering systems, taping units, testing stations, and complete finishing lines.

Using advanced 3D CAD tools and lean, modular design principles, we collaborate closely with clients to deliver machinery that meets specific technical and operational goals. Our focus on concurrent design and customer partnership ensures faster development, smoother implementation, and long-term reliability.

When you work with Itasca Automation Systems, you’re not just purchasing a machine; you’re investing in a relationship built on trust, innovation, and performance. From concept to commissioning, we stand beside our customers to ensure their automation journey delivers measurable, lasting value.

Contact Us Today

The ROI showdown between automated conveyor lines and stand-alone stations is not a contest of cost; it’s a question of strategy. While stand-alone systems may offer short-term affordability, fully integrated automation delivers unmatched long-term gains in productivity, quality, and consistency.

For coil winding manufacturers facing growing demand, tighter tolerances, and global competition, investing in an automated conveyor line isn’t just a modernization step; it’s a competitive necessity.

Ready to evaluate how automation can elevate your production? Connect with Itasca Automation Systems to discuss your process, goals, and challenges. Our team will help you design a precision-engineered system that maximizes ROI, enhances quality, and sets your operation apart.

Contact us today to start your journey toward smarter, leaner, and more profitable coil winding automation.

No responses yet