Electronic Tensioners for Coil Winding

Coil winding is a crucial process in the production of high-quality components such as electric motors and transformers. In order to achieve consistent and precise coils, electronic tensioners play a critical role in dynamically adjusting the tension of the wire in real-time. This not only ensures uniform winding but also prevents material stress and potential wire breakage. Itasca Automation Systems offers a range of high-performing electronic tensioners, including the ETC120, ETC250, and ETC30000, designed to meet the varying needs of coil winding applications.

Ensuring Precise Wire Tension, Real-Time Dynamic Adjustments

When it comes to coil winding, the importance of precise wire tension cannot be overstated. It plays a crucial role in ensuring the overall quality and performance of the winding process. This is where electronic tensioners come into play, offering Innovative solutions that are designed to meet the highest standards of wire tension accuracy and quality control. With the ability to provide real-time dynamic adjustments, these electronic tensioners are an essential component in the production of high-quality, precise coils. Itasca Automation Systems offers a range of advanced electronic tensioners that are tailored to meet the specific requirements of the winding process, ensuring the best possible outcome for manufacturers in need of reliable and high-performance solutions.

When it comes to the production of high-quality coils, Itasca Automation Systems’ Electronic Tensioners stand out as the ultimate solution. The advanced technology and innovative design of these tensioners are specifically engineered to meet the demanding requirements of the coil winding process, offering the highest possible level of quality control and precision. By providing a product range that includes the ETC120, ETC250, and ETC30000, as well as other types of electrical coil winding tensioners and mechanical tensioners, Itasca Automation Systems ensures that customers have access to a comprehensive selection of electronic tensioners that cater to various winding needs, from smaller scale applications to large-scale production processes.

Return Wheel and Tension Release Mechanism

Alongside the precise control of wire tension, the integration of a return wheel and a tension release mechanism further enhances the versatility and efficiency of electronic tensioners. The ability to accommodate the return of thin wires and the implementation of a tension release mechanism for skeined wires are key features that contribute to the overall flexibility and adaptability of the winding process. These additional components work in harmony with the tension control system, ensuring that diverse wire types and specific winding requirements are seamlessly managed, thus leading to the production of consistently high-quality coils.

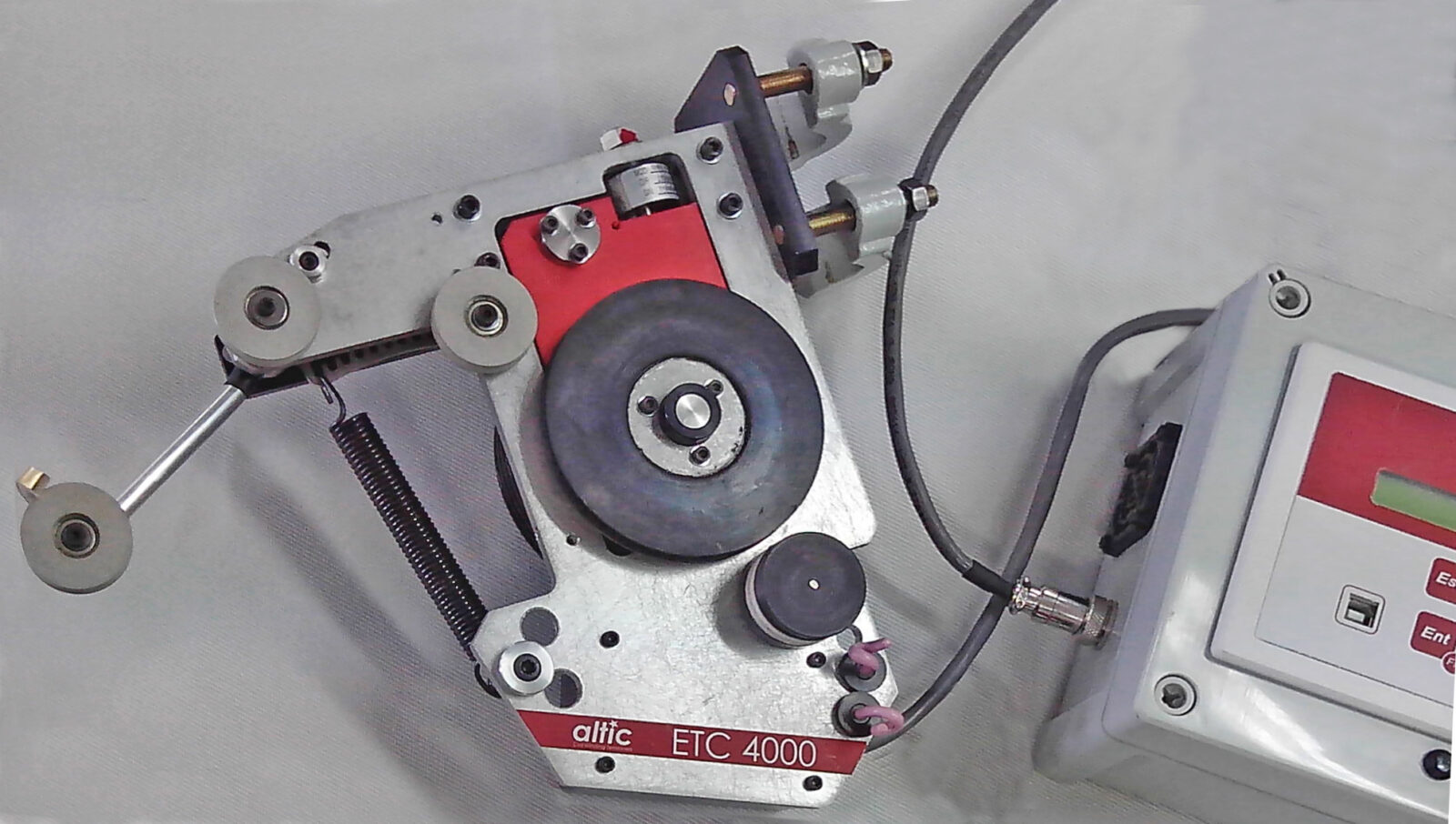

ALTIC ETC120, Closed-Loop Control System, Compact Design for Multi-Spindle Equipment

Another notable example of an advanced electronic tensioner is the ALTIC ETC120, which is characterized by its full front-face wire path design, making it particularly suitable for handling thinner wire ranges. The true closed-loop control system of the ALTIC ETC120, coupled with its automatic wire return management feature, demonstrates its high level of precision and adaptability. Its compact design and suitability for automated, high-dynamic multi-spindle coil winding equipment further highlight its versatility and capability to meet the demanding requirements of modern winding processes.

Itasca Electronic Tensioner Models

Ensuring Precise Wire Tension

By integrating electronic tensioners into the winding process, manufacturers can ensure a level of wire tension precision that is crucial for the production of uniform and high-quality coils. The advanced features and technology incorporated into these tensioners, such as real-time dynamic adjustments and closed-loop control systems, contribute to a consistent and reliable level of wire tension control. This, in turn, leads to the production of coils with uniform dimensions and optimal performance characteristics, thereby meeting the high standards required in various industrial applications.

Real-Time Dynamic Adjustments

The ability of electronic tensioners to perform real-time dynamic adjustments in response to changes in winding speed and material properties is a defining feature that sets them apart. This capability ensures that the wire tension remains constant and within the specified parameters, regardless of the operational conditions, thereby minimizing the risk of material stress and related issues. By adapting to variable parameters in the winding process, these tensioners contribute to the overall efficiency and reliability of coil production, making them an indispensable part of modern, high-precision winding machines.

Example: Meteor Tensioner MDR033A

The Meteor Tensioner MDR033A serves as a prime example of the advanced capabilities and features of electronic tensioners in the coil winding process. With its ability to maintain constant tension, even during rapid changes in winding speed, the MDR033A exemplifies the use of cutting-edge technology, including Fuzzy-Logic control, to achieve a high level of tension accuracy and consistency. Its user-friendly interface and compatibility with various wire types further underscore its position as a leading solution for manufacturers seeking reliable and high-performance tension control for their winding machines.

Fuzzy-Logic Control for Constant Tension

The implementation of Fuzzy-Logic control in the Meteor Tensioner MDR033A is a significant advancement in achieving constant wire tension, even in the face of varying operational conditions. This intelligent control system adapts to the specific requirements of the winding process, ensuring that the tension remains within the desired parameters, thereby minimizing the risk of untoward occurrences such as wire breakage or deformation. Fuzzy-Logic control represents a new era in tension control technology, offering a level of adaptability and precision that is essential for meeting the evolving needs of the coil winding industry.

User-Friendly Interface

One of the standout features of the Meteor Tensioner MDR033A is its user-friendly interface, which is designed to facilitate easy parameter input and real-time monitoring of the winding process. The eight-digit LCD display and the four-button keypad enable operators to access and adjust the tension parameters with ease, ensuring a seamless and efficient operation. This emphasis on user convenience and intuitive design sets the MDR033A apart as a top choice for manufacturers who prioritize not only precision and performance but also ease of use in their winding machinery.

Return Wheel and Tension Release Mechanism

The integration of a return wheel for thin wires and a tension release mechanism for skeined wires further enhances the adaptability and versatility of the electronic tensioners. These additional components work in synergy with the tension control system to ensure that a diverse range of wire types and specific winding requirements are effectively managed, leading to the production of consistently high-quality coils. The incorporation of these mechanisms represents a thoughtful and comprehensive approach to addressing the complexities of the winding process, positioning electronic tensioners as indispensable assets in modern coil manufacturing operations.

Example: ALTIC ETC120

The ALTIC ETC120 serves as a prominent example of an advanced electronic tensioner, distinguished by its true closed-loop control system and compact design tailored for multi-spindle coil winding equipment. The full front-face wire path design of the ALTIC ETC120, combined with its automatic wire return management feature, underscores its high level of precision and adaptability, making it a preferred choice for manufacturers seeking a reliable and efficient tension control solution for their winding machines. This example further highlights the exceptional capabilities of electronic tensioners in meeting the rigorous demands of modern coil manufacturing processes.

Conclusion

Electronic tensioners are crucial components for achieving precision and consistency in coil winding operations. They offer dynamic adjustments, real-time tension control, and user-friendly interfaces, providing significant improvements in productivity and product quality. Itasca Automation Systems offers a wide range of electronic tensioners such as the ETC120, ETC250, and ETC30000, providing the highest level of quality control for any production process. Choose Itasca for your electronic tensioner needs and experience the best in wire tension accuracy.