In the highly competitive world of coil winding and electrical component manufacturing, precision, speed, and consistency are the key drivers of success. Among the critical technologies transforming modern production environments, Itasca’s inline wire stripper stands out as a game changer. These compact yet powerful systems are redefining what’s possible in automated production lines, particularly for businesses that demand accuracy and efficiency at scale.

At Itasca Automation Systems, we’ve seen firsthand how the integration of inline wire strippers into our custom-built machinery dramatically enhances throughput, reduces labor costs, and ensures product consistency.

The Evolution of Wire Stripping in Automation

From Manual to Automated

Wire stripping has traditionally been a manual or semi-automated process, requiring skilled labor to remove insulation from conductors without damaging the wire underneath. While effective in low-volume settings, manual wire stripping can be inconsistent, slow, and expensive when scaled to high-volume applications.

Automated systems improved the process by standardizing strip lengths and minimizing human error. But the real revolution began when inline wire strippers were introduced—machines capable of integrating directly into the production line, stripping wire insulation during the transfer or handling of the wire, without interrupting the production flow.

Precision Engineering Meets Seamless Integration

Inline wire stripping is about more than just removing insulation. These tools represent a marriage of mechanical precision and electronic control, capable of adjusting strip length, depth, and speed in real time. Modern units can handle a variety of wire gauges and insulation types, making them adaptable to diverse product requirements.

What Is an Inline Wire Stripper?

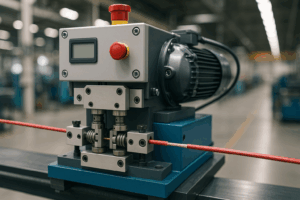

An inline wire stripper is a compact device integrated into automated production machinery that removes insulation from electrical wires during a continuous operation. It eliminates the need for separate stripping steps or additional human handling, allowing for seamless wire preparation within the production cycle.

These systems typically include:

- Precision stripping blades or laser cutters

- Servo motors or pneumatic actuators for controlled motion

- Sensor feedback for real-time adjustment

- Programmable interfaces for setting strip parameters

At Itasca Automation Systems, we incorporate inline wire stripping into coil winding equipment, terminal insertion stations, and soldering modules, creating highly synchronized workflows that eliminate downtime and manual intervention.

Benefits of Inline Wire Stripping in Automated Coil Winding

Staying efficient is paramount to any competitive manufacturing company. And for those who have not implemented these machines, here are the benefits of automated wire stripping machines and coil winders.

1. Higher Throughput with Fewer Bottlenecks

By performing wire stripping in line with the rest of the production process, manufacturers eliminate the delays associated with separate wire prep stages. This drastically increases the number of units processed per hour, a critical metric in high-volume coil manufacturing.

2. Improved Accuracy and Repeatability

Inline strippers are CNC-controlled or servo-driven, ensuring strip lengths are exact, down to a fraction of a millimeter. This level of precision is essential for high-reliability components, such as those used in automotive, aerospace, and medical devices.

3. Reduced Labor Costs and Operator Fatigue

Automating the stripping process removes the need for a dedicated operator to perform repetitive tasks. This not only reduces labor costs but also minimizes ergonomic issues and mistakes caused by fatigue or distraction.

4. Integrated Quality Assurance

Inline systems can be equipped with vision sensors or contact sensors to verify stripping quality in real time. If an anomaly is detected (e.g., a nicked conductor or incomplete strip), the system can flag or reject the part before it proceeds further down the line.

5. Scalability and Flexibility

Modern inline wire strippers can be easily reprogrammed to handle different wire gauges, insulation materials, and strip lengths. This is especially useful for manufacturers producing a wide range of coil sizes and designs on a single line.

Use Case: Inline Wire Stripping in Coil Winding Automation

Itasca Automation Systems specializes in designing and building sophisticated coil winding solutions. In the context of coil production, wire stripping is a critical step that precedes terminal insertion, soldering, or ultrasonic welding.

Here’s how inline stripping fits into our typical process:

Step 1: Wire Feeding and Positioning

Our multi-spindle winding machines feed wire continuously from spools or payoff reels. Tension control ensures even winding and proper alignment.

Step 2: Inline Stripping Before Termination

Before the wire reaches the terminal insertion or soldering station, an inline wire stripper removes a precisely defined section of insulation. The strip length, angle, and depth are configured via our control software and adjusted based on the wire specs.

Step 3: Automated Terminal Insertion or Soldering

With the stripped wire now exposed, the machine inserts the terminal or applies solder with robotic precision. By removing human handling between stripping and soldering, contamination risks are minimized, and electrical contact reliability is enhanced.

Step 4: Inline Testing and Quality Verification

Our systems often include integrated testing stations that verify resistance, continuity, and strip quality. Failed units are automatically rejected or flagged for operator review.

The Role of 3D CAD and Modular Design

Inline wire stripping requires precise mechanical alignment and timing. To achieve this, Itasca’s engineers leverage modern 3D CAD tools and a lean modular design philosophy. This allows us to simulate, prototype, and optimize every motion sequence before a machine hits the production floor.

By designing in modular blocks, we can easily insert or remove inline stripping stations from a system, making upgrades and future adaptations simple. This concurrent engineering approach reduces lead time, minimizes design errors, and ensures the machine fits perfectly within our customer’s existing workflow.

Real-World Results: Impact on Manufacturing Efficiency

Case Study: Automotive Coil Manufacturer

A Tier 1 automotive supplier approached Itasca Automation Systems with a request to improve the production speed and quality of their ignition coil assemblies. The client’s existing line relied on manual stripping and soldering, creating a bottleneck in production and introducing quality variability.

Solution:

We designed a custom coil winding and finishing system that integrated:

- Multi-spindle winding

- Inline wire stripping

- Terminal insertion

- Inline resistance testing

- Robotic part handling

Results:

- 30% increase in throughput

- 40% reduction in scrap due to stripping and soldering errors

- 80% reduction in manual labor associated with wire prep

- Fully integrated quality control with real-time data logging

Key Considerations When Choosing Inline Wire Strippers

If you’re considering inline stripping for your production line, keep the following factors in mind:

1. Wire Specifications

Ensure the stripper can accommodate your full range of wire gauges, insulation types (PVC, Teflon, enamel, etc.), and strip requirements (partial, full, multi-stage).

2. Production Volume

High-speed lines benefit the most from inline stripping, where milliseconds saved per cycle translate to thousands of units per shift.

3. Integration with Existing Equipment

Work with a partner like Itasca Automation Systems that can design the inline stripper to fit within your existing or new system with minimal disruption.

4. Maintenance and Support

Look for systems with modular construction, easy blade replacement, and diagnostics. A strong OEM partner will offer training, spare parts, and field support.

The Future of Inline Wire Stripping

The next evolution of inline wire stripping will be driven by:

- Machine learning algorithms that predict and adjust for wire wear and insulation variation

- Smart sensors that analyze conductor surface quality

- Adaptive tooling for multiple strip geometries in a single pass

- Laser stripping for ultra-fine wire without mechanical contact

As Industry 4.0 principles expand, inline wire stripping will become more autonomous, intelligent, and connected, streamlining the feedback loop between quality control, production control, and equipment maintenance.

Why Partner with Itasca Automation Systems?

At Itasca Automation Systems, we don’t just build machines—we build solutions. Our team of engineers combines decades of experience with the latest in CAD modeling, servo technology, and lean design principles to deliver precision equipment that exceeds expectations.

We specialize in:

- Custom coil winding machinery

- Inline wire stripping and testing

- Terminal insertion and soldering automation

- Modular machine design for easy upgrades

- Collaborative engineering tailored to your specifications

Whether you’re a global OEM or a regional producer looking to improve efficiency, our team is ready to help you modernize your operations and drive long-term growth.

Transform Your Production Line Today

Inline wire strippers are not just a convenience—they are a catalyst for growth in competitive manufacturing environments. They cut costs, improve quality, and accelerate production in ways that manual or batch processes simply cannot match.

If your production line still relies on outdated or manual wire stripping processes, it’s time to explore the advantages of fully integrated, precision inline solutions.

Contact us today to discuss how we can design a custom solution that integrates inline wire stripping with your unique coil winding and finishing requirements.

Comments are closed