Mechanical Tensioners for Coil Winding

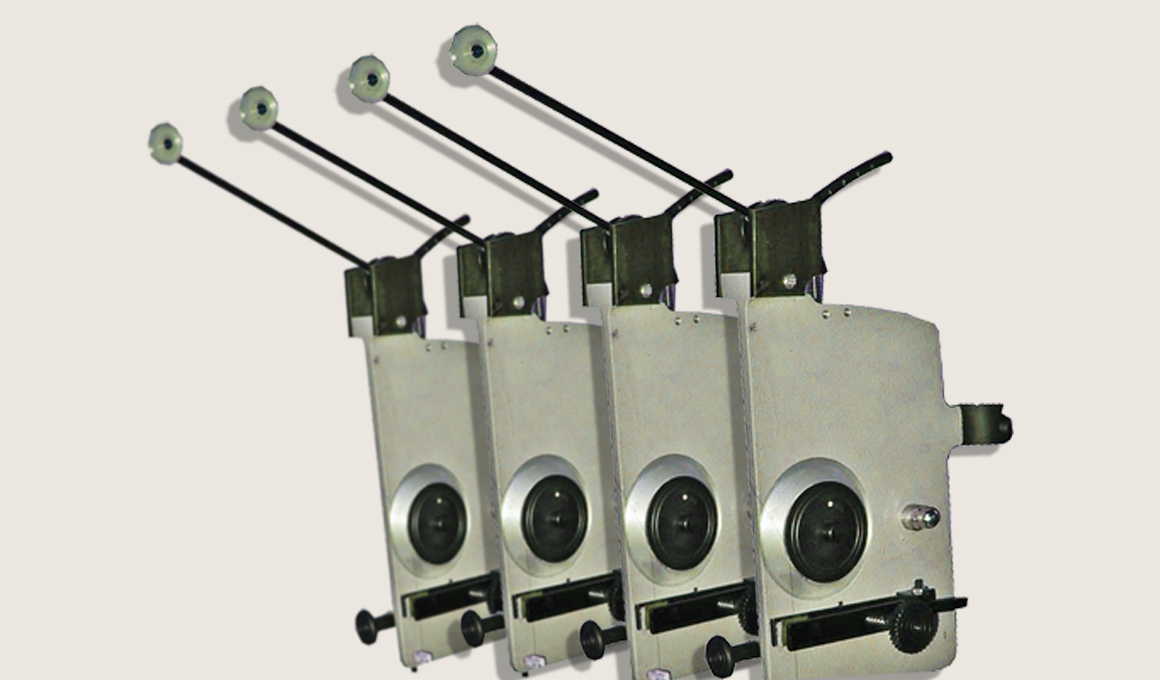

Introducing Mechanical Tensioners for Coil Winding, a crucial component in ensuring precise wire tension during the winding process. With decades of improvements and enhancements, ALTIC’s Mechanical Tensioners are known for their reliability and ease of installation, adjustment, use, and maintenance. The product range includes TF72, F71, M65, and GR64 models, accommodating various wire sizes and providing constant tension to enhance coil quality and production efficiency. Trust in Itasca Automation Systems for top-quality Mechanical Tensioners.

Ensuring Consistent Wire Tension

Mechanical tensioners are vital components in the coil winding process, ensuring that the wire is fed at a consistent tension throughout the winding operation. This is crucial for the precision and quality of the wound coil, as variations in wire tension can lead to defects such as unevenly wound coils, wire breakage, and insulation damage. By employing advanced tension technology, mechanical tensioners play a significant role in the production of high-quality winding configurations.

In addition to preventing wire-related issues, mechanical tensioners also contribute to optimizing the overall coil quality. By providing the necessary control over wire tension, these systems help in maintaining the dimensional accuracy and structural integrity of the wound coils. This, in turn, leads to improved performance and reliability of the end products, making mechanical tensioners an indispensable part of the winding process.

With a focus on ensuring consistent wire tension, mechanical tensioners offer a range of features designed to enhance the winding process. These include easy installation, adjustment, and maintenance, as well as long-lasting reliability. One of the prominent examples is the ALTIC Mechanical Tensioners, which have been the company’s most renowned products for over 30 years and have undergone numerous design improvements to continue providing the highest standards of operational excellence.

Preventing Wire Breakage and Damage

Preventing wire breakage and damage is a primary objective in the coil winding process, and mechanical tensioners excel in this aspect. By maintaining a controlled and uniform wire tension, these devices significantly reduce the likelihood of wire-related issues, ensuring that the winding operation proceeds smoothly and without interruptions. This is particularly crucial in applications where the use of high-speed winding machines is common, as the strain on the wire is greater in such scenarios. With the use of reliable mechanical tensioners, the risk of wire breakage is effectively minimized, leading to increased production efficiency and reduced material waste.

Furthermore, mechanical tensioners help in mitigating the risk of insulation damage that can occur due to inconsistent wire tension. By providing a steady and adjustable tension on the wire, these systems contribute to the overall quality and durability of the wound coils. This level of precision and control is indispensable in industries where the integrity of the winding configuration is critical, making mechanical tensioners a valuable asset in achieving defect-free production.

Another significant advantage of employing mechanical tensioners is their versatility in accommodating different wire sizes. Whether dealing with fine copper wires or larger gauge materials, there are specialized mechanical tensioners available to meet the specific requirements of the winding operation. This versatility and adaptability further reinforce the indispensable role of these devices in ensuring the optimal quality of the final products.

Types of Mechanical Tensioners

There is a diverse range of mechanical tensioners available, each designed to cater to specific winding requirements and accommodate different wire sizes. For instance, the Graduated Mechanical Tensioners are a notable example, designed to handle wire diameters ranging from 0.20 to 2.00 mm. These tensioners are commonly used for precise tension control in various industrial applications. On the other hand, the Fine Wire Dereeler series, including models such as the ME483, ME484, and ME485, is tailored for high-speed dereeling of fine copper wires, with adjustable tension settings to accommodate a wide range of wire diameters.

It’s important to note that the choice of the mechanical tensioner is a crucial decision point in the winding process. Factors such as wire material, diameter, and specific application requirements all play a role in determining the most suitable tensioner for the job. Whether it’s an automatic model with digital display for advanced control, a pneumatic tensioner for high-speed operations, a precision mechanical tensioner for fine wire applications, an Electrical Tensioner, or an Electronic Tensioner for coil winding precision, Itasca’s range of options ensures that there is a perfect solution for every winding process requirement.

Itasca Mechanical Tensioner Models

Accommodating Different Wire Sizes

Accommodating different wire sizes is a fundamental aspect of mechanical tensioners, and it is essential to have a range of options to suit various winding applications. From fine wire applications where lightweight and sensitive tensioners are required to heavy-duty solutions for larger gauge wires, the ability to handle different wire sizes represents a core capability of mechanical tensioners. This ensures that regardless of the specific demands of the winding process, there is a suitable and effective tensioner available to maintain the required wire tension.

With technology-driven advancements, modern mechanical tensioners are equipped with features that not only enable them to handle a broad spectrum of wire sizes but also provide consistent and reliable performance. This adaptability and precision in accommodating different wire sizes make mechanical tensioners an indispensable component in industries where the quality and integrity of the wound coils are of utmost importance.

Maintaining Constant Tension

One of the primary functions of mechanical tensioners is to maintain constant tension on the wire throughout the winding process. This is essential for ensuring that the wire is fed at a consistent rate, thereby contributing to the uniformity and quality of the wound coil. By utilizing advanced tension technology, these systems are capable of providing precise and stable wire tension control, even in demanding and high-speed winding applications.

A key feature of mechanical tensioners is their ability to sustain constant tension, accommodating variations in winding speed and wire spool dimensions. This level of adaptability is crucial for industries where the winding process may involve diverse wire materials and dimensions, making the ability to maintain consistent wire tension a central requirement for the success of the operation. Whether it’s a small, intricate winding application or a large-scale industrial operation, the maintenance of constant wire tension is a defining factor in the production of high-quality, defect-free winding configurations.

Optimizing Coil Quality

Optimizing coil quality is a multifaceted objective that encompasses various aspects of the winding process, with consistent wire tension being a critical component. Mechanical tensioners play a direct role in this optimization by ensuring that the wire is fed at a uniform tension, thereby contributing to the overall uniformity, dimensional accuracy, and structural integrity of the wound coils. This level of precision and control is indispensable in industries where the quality and performance of the wound coils are paramount, and any variations or defects can have significant implications for the end products.

By creating a consistent and controlled winding environment, mechanical tensioners enable the production of high-quality, tightly wound coils that meet the stringent demands of precision-engineered applications. This focused approach to winding excellence is a defining characteristic of mechanical tensioners, making them an essential tool for optimizing coil quality and elevating the standards of winding technology.

Enhancing Production Efficiency

In addition to ensuring consistent wire tension and optimizing coil quality, mechanical tensioners also contribute to enhancing production efficiency in the winding process. By preventing wire-related issues such as breakage and damage, these systems help in streamlining the production workflow, reducing downtime, and minimizing material wastage. Furthermore, the ability to accommodate different wire sizes and maintain consistent tension across a wide range of applications results in improved versatility and adaptability, allowing for greater operational flexibility and efficiency.

Moreover, the ease of installation, adjustment, and maintenance associated with mechanical tensioners directly contributes to the overall efficiency of the production process. With advanced features that simplify the winding setup and provide seamless tension control, these systems are engineered to elevate the productivity and throughput of the winding operation, driving process optimization and enhanced operational performance.

Reducing Defects in Final Products

One of the most significant impacts of employing mechanical tensioners is the substantial reduction in the likelihood of defects in the final products. By maintaining consistent wire tension and preventing issues such as wire breakage, insulation damage, and dimensional inaccuracies, these systems play a pivotal role in ensuring the quality and reliability of the wound coils. This has far-reaching implications for the performance and structural integrity of the end products, where the elimination of defects translates to improved reliability, safety, and overall customer satisfaction.

By mitigating the risk of wire-related issues and optimizing the overall winding process, mechanical tensioners are instrumental in producing defect-free winding configurations, thereby reinforcing the reputation and credibility of the businesses utilizing these advanced tension technologies. This focus on reducing defects and enhancing the quality of the final products underscores the indispensable role of mechanical tensioners in driving industry-wide improvements and maintaining the highest standards of winding excellence.

Ensuring Consistent Wire Tension

The importance of ensuring consistent wire tension in the coil winding process cannot be overstated, as it forms the cornerstone of the entire winding operation’s precision and quality. Whether it’s for fine wire applications, heavy-duty industrial uses, or intricate winding configurations, the need for dependable and adjustable wire tension is universal across the winding industry. Mechanical tensioners, with their advanced tension technology, remain at the forefront of providing the necessary control and stability to ensure that the wire feeding process is flawless, reliable, and conducive to producing the highest standard of wound coils.

Preventing Wire Breakage and Damage

Preventing wire breakage and damage is a critical aspect of the winding process, and mechanical tensioners excel in safeguarding the wire from issues that could compromise the integrity and reliability of the wound coils. By maintaining controlled and uniform wire tension, these devices minimize the risk of breakage and insulation damage, ensuring that the winding operation proceeds smoothly and without disruptions. This proactive approach to preventing wire-related issues is essential for maintaining the overall quality and performance of the wound coils, making mechanical tensioners an indispensable link in the production chain of high-quality winding configurations.

Accommodating Different Wire Sizes

The ability to accommodate different wire sizes is a defining characteristic of mechanical tensioners, representing a core capability that directly impacts the flexibility and versatility of the winding operation. By offering a comprehensive range of options, from fine wire applications to larger gauge materials, mechanical tensioners ensure that the specific demands of every winding process are met with precision and reliability. This adaptability and the seamless handling of varied wire sizes underscore the indispensable role of mechanical tensioners in driving uniformity, quality, and efficiency in the coil winding process.

Contact Itasca today about our Mechanical Tensioners.

Itasca’s Mechanical Tensioners are essential components for coil winding processes. With their user-friendly design, reliability, and long lifespan, they ensure consistent wire tension and prevent issues such as breakage and damage. Available in a range of models to accommodate different wire sizes, these tensioners optimize coil quality, enhance production efficiency, and reduce defects in final products. Trust Itasca Automation Systems for the best Mechanical Tensioners on the market.