Coil Winding Machines: A Beginner’s Walk-Through

When it comes to manufacturing components like transformers, electric motors, sensors, and inductors, precision is everything. At the heart of many of these devices lies a simple but critical process: winding wire into tightly controlled coils. This is where a coil winder machine comes in. For those new to the industry, understanding how these machines operate can seem overwhelming, but with the right breakdown, the fundamentals become much clearer.

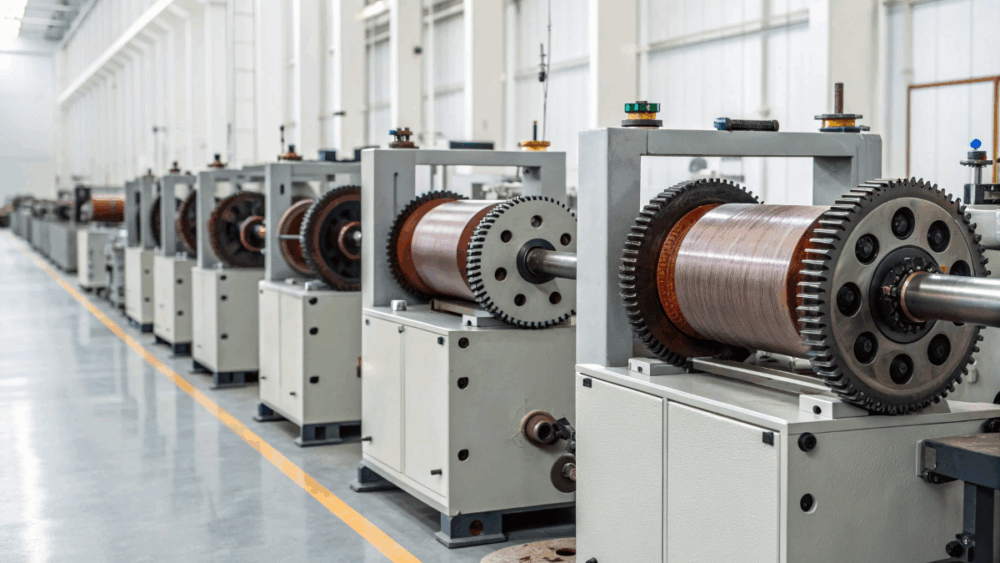

What Is a Coil Winder Machine?

A coil winder machine is a specialized piece of equipment designed to wind wire around a core or bobbin in precise patterns and configurations. The result is a coil that can be used in countless electrical and electronic applications.

While manual winding can be performed on a very small scale, industrial applications require exact consistency, high speed, and repeatability. Automated coil winding machines eliminate the possibility of human error, ensuring accuracy down to fractions of a millimeter.

The Basic Components of a Coil Winder

Though designs vary depending on application and level of automation, most coil winder machines share a set of core components:

- Spool Holder: Houses the wire supply and ensures smooth unwinding.

- Wire Guide System: Directs the wire into the precise position on the bobbin or core.

- Bobbin or Mandrel Holder: The rotating fixture that supports the component being wound.

- Traverse Mechanism: Moves the wire guide laterally so the wire lays evenly across the bobbin.

- Drive System: Provides controlled rotation and speed, usually powered by precision motors.

- Control Unit: The “brain” of the machine, responsible for managing speed, tension, pitch, layering, and patterns.

When integrated with automation, additional modules such as soldering units, taping mechanisms, or quality control testers can be included, turning the coil winder into a fully automated production cell.

How the Coil Winding Process Works

Let’s break the process down into sequential steps:

- Wire Setup: The operator or automated feeder loads the wire spool into the spool holder. Proper tension is applied to prevent slack or snapping.

- Core Placement: The bobbin or core is mounted onto the mandrel. In automated setups, robotic arms can handle this step.

- Initialization: The machine’s control system sets winding parameters such as turns, pitch, and layer count.

- Winding: The drive system rotates the mandrel while the traverse mechanism guides the wire across the core, laying it down in consistent layers.

- Termination: Once the winding is complete, the wire is cut and either soldered, crimped, or connected to terminals automatically.

- Finishing: Additional processes like taping, resin coating, or electrical testing may be performed before the coil is released from the machine.

This seamless integration of steps reduces handling time, increases throughput, and ensures repeatability.

Types of Coil Winder Machines

Not all coil winders are alike. Different industries and applications require tailored solutions. Here are some common types:

1. Manual Winders

These are basic machines where operators guide the wire by hand. They’re suitable for prototyping or low-volume production but lack the speed and precision required for industrial use.

2. Semi-Automatic Winders

These machines feature powered mandrels but still require operator involvement for tasks like wire guiding or terminal insertion. They offer a middle ground between manual and fully automated solutions.

3. Automatic Single-Spindle Winders

These machines automate nearly all aspects of the process for one coil at a time. They’re ideal for mid-volume runs and allow for greater consistency and efficiency.

4. Multi-Spindle Winders

Designed for high-volume production, these machines wind multiple coils simultaneously. They’re heavily used in industries like automotive, where thousands of identical coils may be needed daily.

5. Specialty Winders

Some coils require unique geometries or winding patterns, such as toroidal coils. Specialty machines are built to handle these complex designs.

Why Precision Matters in Coil Winding

Precision isn’t just a matter of aesthetics—it directly impacts performance. For example:

- Electrical Performance: Uneven winding can lead to inconsistent inductance, resistance, and efficiency.

- Heat Dissipation: Proper winding ensures better thermal characteristics, preventing overheating.

- Reliability: Precision winding reduces the chance of shorts, weak spots, or coil failures.

In industries like aerospace, automotive, and medical devices, where reliability is mission-critical, precision coil winding isn’t optional—it’s essential.

The Role of Automation in Coil Winding

Modern coil winder machines incorporate automation to enhance accuracy, consistency, and productivity. Automation offers several key advantages:

- Speed: Automated systems can wind thousands of turns in a fraction of the time it would take manually.

- Repeatability: Once programmed, the machine can reproduce identical coils with zero variation.

- Integrated Processes: Terminal insertion, soldering, taping, and testing can all be combined into a single automated line.

- Quality Control: Sensors and inspection systems detect errors instantly, preventing defective parts from moving forward.

Automation also reduces reliance on skilled manual labor, which can be a limiting factor for scaling production.

Advanced Features in Modern Coil Winder Machines

The evolution of coil winding machinery has introduced a variety of advanced features, including:

- Programmable Logic Controllers (PLCs): Allow for highly customizable winding programs.

- Touchscreen Interfaces: Simplify setup and monitoring.

- Closed-Loop Tension Control: Ensures consistent wire tension across all turns.

- Vision Systems: Provide real-time monitoring and defect detection.

- CAD Integration: Enables design files to directly inform winding patterns.

- Data Collection: Tracks production output, error rates, and efficiency for process optimization.

At Itasca Automation Systems, for example, our approach uses modern 3D CAD tools and a lean modular design philosophy to create machines that meet exact customer requirements while staying adaptable for future needs.

Industries That Depend on Coil Winder Machines

Coil winder machines support a wide range of industries, including:

- Automotive: Ignition coils, sensors, and electric motor components.

- Consumer Electronics: Transformers, speakers, and inductors.

- Aerospace & Defense: High-reliability coils for navigation and communication systems.

- Medical Devices: MRI equipment, sensors, and precision motors.

- Industrial Equipment: Robotics, power supplies, and control systems.

Each sector demands its own levels of precision, speed, and customization, making versatility in coil winder machine design critical.

The Itasca Automation Systems Difference

Located on the scenic Door County Peninsula in Wisconsin—an area known internationally for custom yacht and shipbuilding and as a leading cherry-growing region—Itasca Automation Systems brings a unique blend of craftsmanship and innovation to coil winding automation.

Our engineers specialize in designing automated multi-spindle winders and integrated systems for terminal insertion, soldering, taping, testing, and other finishing processes. What sets us apart is our collaborative design approach, working closely with clients to develop machines that fit their exact needs.

By leveraging concurrent engineering and 3D CAD modeling, we create machines that are modular, efficient, and future-ready. This lean approach means our solutions not only solve today’s challenges but also adapt to tomorrow’s opportunities.

Why Choose an Automated Partner for Coil Winding?

Choosing the right partner for coil winding automation is not just about buying a machine; it’s about investing in efficiency, reliability, and long-term growth. The right machine:

- Lowers costs by reducing waste and increasing throughput.

- Enhances quality by ensuring every coil meets specifications.

- Scales with your production needs.

- Provides peace of mind through reliable, collaborative support.

Final Thoughts

A coil winder machine may seem like a niche piece of equipment, but its role in modern manufacturing is indispensable. From electric vehicles to medical equipment, precision coils power the devices and systems that drive our world.

Understanding how these machines work is the first step toward appreciating the critical role they play in quality manufacturing. For companies aiming to stay ahead, investing in advanced, automated coil winding systems is not just a competitive advantage—it’s a necessity.

Contact Us Today

At Itasca Automation Systems, we take pride in designing and building coil winding machines that go beyond standard expectations. Whether you need a multi-spindle high-volume system, integrated finishing processes, or a completely custom solution, our team is ready to collaborate with you every step of the way.

Contact us to learn how our expertise can power your next project. Let’s create innovative, reliable, and cost-effective coil winding solutions together.

Comments are closed