Top 10 Tips for Choosing the Best Automatic Coil Machine for Your Needs

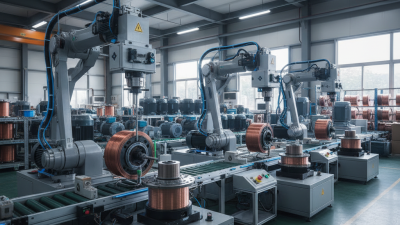

When it comes to modern manufacturing, the importance of selecting the right equipment cannot be overstated. The automatic coil machine has become an essential tool in various industries, from automotive to electronics, offering efficiency and precision that manual options simply cannot match. According to a recent report by the International Association of Advanced Manufacturing, nearly 60% of companies have seen substantial improvements in productivity and product quality after integrating advanced automatic coil machines into their operations. This heightened demand for automation has driven innovation in coil processing technology, making the selection process more critical than ever.

As manufacturing processes evolve, the diversity of automatic coil machines available on the market can be overwhelming. A study by the Manufacturing Technology Association indicates that manufacturers who invest in the right automatic coil machine can see a return on investment of up to 30% within the first year of usage. However, choosing the best automatic coil machine tailored to one's specific needs requires a keen understanding of both the operational requirements and the capabilities of various models. In this guide, we will explore the top ten tips to facilitate the selection of an automatic coil machine that maximizes efficiency, reduces waste, and enhances overall production quality, ensuring that businesses can thrive in a competitive landscape.

Understanding the Basics of Automatic Coil Machines

Automatic coil machines have become essential tools in various industries, providing efficiency and precision when shaping and winding coils. Understanding the basics of these machines is crucial for selecting the right one for your needs. At the core of their functionality, automatic coil machines utilize advanced mechanisms such as programmable logic controllers (PLC) and servo motors, which enable precise control over the winding process. This ensures consistent coil dimensions and reduces human error, making them highly suitable for high-volume production environments.

When choosing an automatic coil machine, it is important to consider the different types available, such as flat coil machines, toroidal coil machines, and spring winding machines. Each type is designed for specific applications and may vary in features such as wire gauge compatibility, coil size capacity, and speed of operation. Additionally, understanding the adaptability of the machine to various materials can play a crucial role in its versatility and longevity in your operations. By comprehensively grasping these fundamentals, users can make better-informed decisions that align with their production requirements and workflow efficiency.

Identifying Your Specific Coil-Winding Needs

When selecting an automatic coil machine, the first step is to clearly identify your specific coil-winding needs. This involves understanding the types of coils you will be producing, as different applications require varying specifications. Consider factors such as wire gauge, coil size, and the number of layers you intend to wind. For example, if your projects involve high precision requirements, you may need a machine that offers finer control over tension and winding speed.

Additionally, think about the materials you’ll be using and the environmental considerations of your workspace. Coils made from different types of wire may require varying machine settings or even unique features in a coil machine. Assess how heavy your production runs will be and what level of automation you require. If you're looking for flexibility, a machine with configurable settings might be the best choice, allowing you to easily switch between different coil types as project demands change.

By thoroughly understanding your needs, you can focus on features that add value, ensuring that the coil machine you choose will enhance your production efficiency and meet your specific requirements.

Evaluating Key Features and Specifications

When selecting the best automatic coil machine for your needs, it's crucial to evaluate key features and specifications that can significantly impact performance and efficiency. One of the primary considerations is the machine's speed and precision capabilities. According to a report from the International Manufacturing Technology Show (IMTS), machines with higher RPM (Revolutions Per Minute) ratings can enhance productivity by up to 30%, making it essential to align the machine’s specifications with your production requirements. Additionally, look for machines with advanced tension control systems, as maintaining consistent tension is vital for quality output, reducing the risk of errors and material wastage.

Another critical factor to assess is the versatility of the machine. A model that offers adjustable settings and multiple coil sizes can accommodate a wider range of applications, as highlighted in the 2022 State of Manufacturing report, which indicates that over 60% of manufacturers required multipurpose machines to adapt to diverse production demands. Furthermore, the durability and maintenance needs of the machine should not be overlooked; machines made with high-quality materials and offering easy maintenance features tend to have longer lifespans and lower operational downtime, aligning well with the goal of sustainable manufacturing practices. By focusing on these key specifications, you will be better equipped to choose an automatic coil machine that meets your operational needs efficiently.

Comparing Brand Reputation and Reviews

When choosing the best automatic coil machine for your specific needs, evaluating brand reputation and customer reviews plays a crucial role. The experiences shared by other users can provide valuable insights into the machine's performance, durability, and customer service. Look for brands that consistently receive positive feedback and have a history of satisfied customers. Online platforms and forums can be excellent resources to gather this information, as they often reflect the true opinions of users who have firsthand experience with the product.

In addition to reviews, consider the features that matter most to you. For instance, look for machines that offer adjustable tension settings or user-friendly interfaces. These features can significantly enhance your experience and ensure that the machine meets your expectations. Checking for warranty and support options from the brand is also essential, as this adds a layer of security to your investment.

Ultimately, the balance of reputable brands and informed user reviews will help you make a more confident decision. Seek out machines that have proven their worth over time while aligning with your personalized requirements and preferences.

Budget Considerations for Coil Machine Purchase

When considering the purchase of an automatic coil machine, budget is a crucial factor that can significantly influence your decision-making process. First, it's essential to establish a clear budget range based on your specific needs and expected usage. This involves evaluating not just the initial purchase price, but also other associated costs such as maintenance, parts replacement, and operational expenses. A well-planned budget will help you narrow down your options and avoid any financial strain in the long term.

Additionally, when evaluating machines within your budget, it is vital to compare features and specifications that align with your production requirements. Cheaper machines may lack certain functionalities that enhance efficiency or offer better quality, which could lead to higher costs over time due to repairs or replacements. It's beneficial to research the long-term value of your investment; sometimes spending slightly more upfront can save substantial amounts down the line by providing better durability and performance. This thorough approach to budgeting ensures that you choose a machine that balances cost with quality, meeting your operational needs effectively.

Top 10 Features to Consider When Choosing an Automatic Coil Machine

This chart represents the top 10 features to consider when selecting an automatic coil machine based on customer preferences and budget considerations.

Related Posts

-

5 Essential Tips for Choosing the Right Wire Winding Machine: Boost Efficiency by 30%

-

Revolutionizing Efficiency How Motor Winding Automatic Machines Transform Manufacturing

-

10 Best Motor Winding Coil Machines for Efficient Production in 2023

-

How to Choose the Best Micro Coil Winding Machine for Your Needs

-

How to Choose the Best Automatic Coil Winding Machine for Your Business Needs

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide