Top 5 Motor Stator Winding Machines for Efficient Coil Production

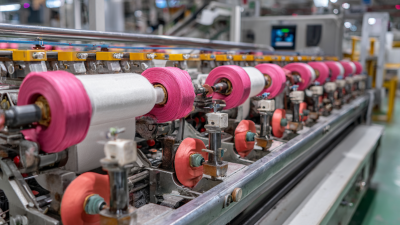

The demand for efficient and high-quality coil production in the electric motor industry has reached unprecedented levels, driven by advancements in technology and the increasing need for energy-efficient systems. According to a recent market research report by Grand View Research, the global electric motor market is expected to reach $184.3 billion by 2025, growing at a CAGR of 4.4%. This growth is closely tied to the rise in demand for electric vehicles and renewable energy solutions, magnifying the need for sophisticated manufacturing equipment, including the pivotal motor stator winding machine.

In this competitive landscape, manufacturers are increasingly turning to automated solutions to enhance productivity and maintain quality standards. The evolution of motor stator winding machines has played a crucial role in streamlining the production process, enabling companies to achieve higher output rates while minimizing material waste. A notable report from Technavio estimates that the global market for winding machines is set to attain a valuation of $570 million by 2024, showcasing the significance of these machines in pioneering efficient coil production.

This article will explore the top five motor stator winding machines currently available in the market and examine how they contribute to improved manufacturing efficiency and better product performance, ultimately supporting the dynamic needs of the electric motor sector.

Best Practices for Selecting Motor Stator Winding Machines Based on Efficiency

When selecting motor stator winding machines, efficiency should be the primary criterion guiding your decision. Key factors to consider include the machine's winding speed, precision, and adaptability to various coil designs. Machines that offer higher winding speeds can significantly enhance production rates, resulting in better throughput. However, it's equally vital to ensure that increased speed does not compromise the quality and consistency of the coils produced. Advanced machines often come equipped with features such as automatic tension control and real-time monitoring systems, which can greatly improve accuracy during the winding process.

Another critical aspect is the machine's ease of use and maintenance. Opt for models that are user-friendly, with intuitive interfaces and straightforward programming capabilities. This will reduce the learning curve for operators and minimize downtime during setup. Additionally, consider machines that come with strong customer support and training resources, as these will be instrumental in maximizing machine efficiency over time.

By prioritizing these best practices, manufacturers can select motor stator winding machines that not only streamline production processes but also enhance overall product quality.

Top Features to Look for in High-Performance Coil Production Equipment

When selecting high-performance motor stator winding machines, certain key features can significantly enhance coil production efficiency. Firstly, precision winding capabilities are critical. Machines that offer advanced tension control and automated wire path adjustments can ensure consistent coil quality, reducing the likelihood of defects. Additionally, machines equipped with multi-spindle systems allow for simultaneous winding of multiple coils, drastically improving throughput and productivity.

Another essential feature is the integration of smart technology. Machines that come with software for real-time monitoring and data analysis enable operators to track performance metrics, identify inefficiencies, and optimize the winding process. Furthermore, user-friendly interfaces enhance operator efficiency, allowing for quick setup and adjustments. Lastly, robust safety features and easy maintenance options are vital for minimizing downtime and ensuring a safe working environment. By prioritizing these features, manufacturers can invest in equipment that not only meets their current production needs but also adapts to future demands in coil production.

Top 5 Motor Stator Winding Machines: Efficiency Comparison

This bar chart presents the efficiency ratings of the top 5 motor stator winding machines based on their production speed and precision in coil manufacturing.

Comparison of Leading Motor Stator Winding Machines by Production Speed

In the competitive landscape of electric motor manufacturing, production speed is a pivotal factor that directly impacts efficiency and profitability. The latest reports from industry analysts indicate a growing demand for advanced motor stator winding machines, which are engineered to deliver superior productivity. For instance, machines equipped with servo-driven technology can boost production rates by as much as 30%, drastically reducing cycle times. Furthermore, innovative features such as automatic wire tension control ensure consistent quality while optimizing throughput.

When selecting the right machine for coil production, it’s essential to consider not just the output speed but also the machine's integration capabilities with existing systems. A seamless integration can enhance operational efficiency, allowing manufacturers to capitalize on their investments quickly. According to a recent market research study, manufacturers that upgraded to high-speed winding machines observed a 25% increase in overall operational efficiency within the first year.

Tips: To maximize efficiency, invest in training operators thoroughly on the new technology. Proper knowledge can significantly reduce setup times and improve the overall production flow. Additionally, regular maintenance of winding machines is crucial to avoid downtime and maintain optimal performance. Setting up a preventive maintenance schedule can result in up to 15% less unplanned downtime.

Top 5 Motor Stator Winding Machines for Efficient Coil Production - Comparison of Leading Motor Stator Winding Machines by Production Speed

| Machine Model | Production Speed (Coils/hour) | Winding Type | Max Coil Size (mm) | Automation Level |

|---|---|---|---|---|

| Model A | 300 | Random Winding | 50 | Fully Automated |

| Model B | 250 | Concentric Winding | 60 | Semi-Automated |

| Model C | 280 | Layer Winding | 55 | Fully Automated |

| Model D | 320 | Cross Winding | 65 | Fully Automated |

| Model E | 270 | Spiral Winding | 58 | Semi-Automated |

Innovative Technologies Enhancing Coil Production Efficiency in Stator Winders

The evolution of motor stator winding machines has significantly enhanced coil production efficiency, leveraging innovative technologies that cater to the demands of modern manufacturing. According to a recent report by MarketsandMarkets, the global market for stator winding machines is expected to reach $1.5 billion by 2025, growing at a CAGR of 5.3%. This surge is largely attributed to the integration of advanced automation and AI-driven processes, which streamline production and reduce cycle times.

One notable advancement is the implementation of intelligent winding techniques, which optimize the placement of coil wires to minimize waste and increase the precision of winding patterns. Moreover, the introduction of real-time monitoring systems allows manufacturers to track machine performance and product quality continuously. A study by Research and Markets indicates that facilities utilizing these technologies experience productivity boosts of up to 30%, significantly outperforming traditional winding methods. As the demand for electric motors climbs, these innovative stator winding machines are poised to play a critical role in meeting market needs efficiently.

Cost-Effectiveness of Top Motor Stator Winding Machines for Large Scale Production

When it comes to large-scale coil production, the cost-effectiveness of motor stator winding machines plays a crucial role in maximizing profitability. Choosing the right machine not only lowers the initial investment but also minimizes long-term operational costs, improving overall production efficiency. Machines that offer features such as automatic winding processes, adjustable speed settings, and modular designs tend to provide better return on investment. These capabilities help manufacturers streamline their operations, reduce waste, and enhance productivity.

In addition to reducing direct costs, advanced winding machines often come with integrated technologies that facilitate real-time monitoring and quality control. This ensures that products meet stringent standards, thus minimizing rework and returns that can be costly for production lines. Furthermore, machines that feature energy-efficient designs can significantly lower power consumption, providing additional savings. By selecting stator winding machines that combine affordability with innovative functionalities, manufacturers can achieve a balance that supports large-scale production while ensuring a strong bottom line.

Related Posts

-

2025 Top 5 Used Coil Winding Machines You Need for Your Business

-

Revolutionizing Efficiency How Motor Winding Automatic Machines Transform Manufacturing

-

What is Automated Machine Learning Its Impact on Industry Growth and Efficiency

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

How to Choose the Best Motor Coil Winding Machine for Your Needs in 2025