5 Essential Tips for Choosing the Right Wire Winding Machine: Boost Efficiency by 30%

Choosing the right wire winding machine can significantly enhance your production efficiency, making it a crucial decision for manufacturers in various industries. With the demand for high-quality products increasing, it's essential to select a machine that not only meets your specific requirements but also streamlines your winding processes. The right wire winding machine can boost efficiency by up to 30%, enabling businesses to maximize output while minimizing operational costs.

In this guide, we will explore five essential tips to help you navigate the selection process, ensuring that your investment in a wire winding machine pays off in the long run. From understanding the technical specifications to assessing the machine's compatibility with your current production setup, these insights will empower you to make an informed choice. Whether you are upgrading existing equipment or purchasing for the first time, keeping these factors in mind will lead to improved productivity and product quality in your operations.

Understanding Wire Winding Machine Specifications for Improved Productivity

When selecting a wire winding machine, understanding its specifications is crucial for enhancing productivity. Key features such as winding speed, torque capabilities, and coil size compatibility directly impact the efficiency of the production process. A machine with adjustable winding speed can accommodate varying production demands, allowing operators to optimize performance without sacrificing quality. Furthermore, torque control is essential for handling different wire materials, ensuring consistent tension and preventing damage to the wire.

In addition to speed and torque, consider the machine's construction and technology. A robust design minimizes downtime for maintenance, while advanced technology, such as programmable logic controllers (PLC), offers precision in winding patterns. Machines with user-friendly interfaces facilitate quick setup and troubleshooting, reducing the learning curve for operators. Evaluating these specifications ensures that the chosen wire winding machine meets operational needs, ultimately boosting productivity by up to 30%.

Evaluating Automation Features to Enhance Operational Efficiency in Wire Winding

When choosing a wire winding machine, evaluating automation features is crucial for enhancing operational efficiency. As the global coil winding machine market experiences rapid growth, driven by a surge in demand for automation and precision, manufacturers must prioritize technology that streamlines processes and reduces manual labor. Automation not only increases productivity but also ensures consistent quality in the winding process.

One essential tip when selecting a wire winding machine is to assess the level of automation offered. Machines equipped with advanced automation capabilities can drastically reduce error rates and improve turnaround times. Additionally, consider the ease of integration with existing systems. A seamless connection to other automated solutions in your facility can further enhance the overall efficiency of your operations.

Another important factor is the machine's adaptability to various winding applications. Look for models that offer flexible programming options, enabling operators to adjust configurations quickly for different projects. This adaptability can boost productivity by ensuring that the winding machine can handle diverse tasks without needing extensive downtime or reconfiguration. Embracing these automation features can position your business at the forefront of the competitive wire winding industry.

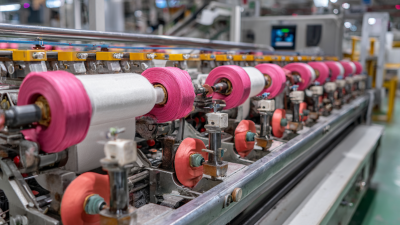

The Role of Material Compatibility in Maximizing Wire Winding Output

When selecting a wire winding machine, material compatibility emerges as a critical factor influencing overall efficiency and output. Different materials, such as copper, aluminum, or specialized alloys, each require distinct winding characteristics and adjustments. Choosing a machine that accommodates the specific wire material not only ensures smoother operation but also minimizes wear and tear on the equipment. An incompatible material can lead to inefficiencies such as increased friction, poor winding quality, and machine downtime for adjustments.

Moreover, the right wire winding machine can enhance wire handling and feeding processes tailored to the selected material. Features like automatic tension control and precise winding speed adjustments are essential when working with delicate or variable-diameter wires. By prioritizing material compatibility, manufacturers can maximize production rates, reduce error rates, and ultimately boost overall output by up to 30%. Investing time in evaluating the material requirements upfront can yield significant long-term benefits in productivity and operational cost savings.

Assessing Maintenance and Support Options to Reduce Downtime by 15%

When choosing a wire winding machine, assessing maintenance and support options is crucial to minimizing downtime and maximizing productivity. A machine that is well-supported by its manufacturer can significantly enhance operational efficiency. Opting for a provider that offers comprehensive maintenance packages, including regular check-ups and quick-response troubleshooting, is essential. A proactive maintenance approach not only extends the lifespan of the equipment but also prevents unexpected malfunctions that could lead to costly delays.

Moreover, it's important to evaluate the availability of spare parts and technical assistance when selecting a wire winding machine. A manufacturer with a robust supply chain can ensure that necessary components are readily available, reducing wait times during repairs. Consider whether they offer remote support and on-site services, as these can be crucial in quickly resolving issues. By prioritizing these support options, businesses can effectively reduce their downtime by up to 15%, enhancing overall efficiency and productivity in their operations. Ultimately, investing time in this assessment will pay off in the long run, leading to smoother operations and a more reliable production schedule.

Efficiency Boost & Downtime Reduction: Wire Winding Machine Analysis

This chart illustrates the improvement in efficiency and reduction in downtime before and after upgrading the wire winding machine. There is a notable increase in efficiency by 30% and a significant drop in downtime by 15% with the right equipment.

Leveraging Technology Integration to Boost Wire Winding Machine Performance

In today's manufacturing landscape, leveraging technology integration is crucial for enhancing the performance of wire winding machines. By incorporating advanced automation, Internet of Things (IoT) capabilities, and data analytics, manufacturers can significantly improve the efficiency and precision of their winding processes. These technologies not only streamline operations but also enable real-time monitoring and adjustments, ensuring optimal performance and reduced downtime.

Furthermore, adopting cutting-edge software solutions can facilitate better management of winding configurations and processes. With technology-driven insights, companies can make informed decisions related to machine settings, material usage, and production schedules, ultimately leading to a boost in productivity by as much as 30%. Emphasizing technology integration allows manufacturers to stay competitive while maximizing output and minimizing errors in wire winding applications.

Related Posts

-

Revolutionizing Efficiency How Motor Winding Automatic Machines Transform Manufacturing

-

Top 5 Motor Stator Winding Machines for Efficient Coil Production

-

How to Choose the Best Motor Coil Winding Machine for Your Needs in 2025

-

2025 Top 5 Used Coil Winding Machines You Need for Your Business

-

What is Automated Machine Learning Its Impact on Industry Growth and Efficiency

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production