Essential Tips for Choosing the Right Motor Winding Machine for Your Needs

The selection of a motor winding machine is a critical decision for manufacturers in the electrical engineering sector. According to a report by Market Research Future, the global market for electric motor winding machines is anticipated to grow at a CAGR of 4.5% over the next five years, driven by the rising demand for electric motors across various industries, including automotive, aerospace, and consumer electronics. As companies strive for increased efficiency and reduced production costs, the right motor winding machine can significantly impact overall operational success.

Understanding the complexities involved in selecting a motor winding machine is essential. Factors such as the machine’s capacity, winding technology, and automation levels contribute to its performance and suitability for specific applications. Additionally, the increase in the production of energy-efficient motors aligns with sustainability trends, thereby raising the bar for the capabilities required in modern winding machines. Thus, equipping oneself with essential knowledge and insights will enable decision-makers to make informed choices that cater to their unique production needs while maximizing potential returns on investment.

Advantages of Different Types of Motor Winding Machines in Industry

When selecting a motor winding machine, it's crucial to consider the advantages offered by different types to ensure your specific needs in the industry are met. Automatic winding machines, for example, provide high precision and efficiency. They are ideal for large-scale production environments where consistency and speed are essential. The automation of these machines not only reduces human error but also minimizes the time spent on each winding task, allowing businesses to increase output without sacrificing quality.

On the other hand, manual winding machines are favored in smaller operations or specialized applications where flexibility is key. These machines allow for greater control over the winding process, enabling technicians to easily adjust settings for unique motor designs or repairs. Additionally, they tend to have lower initial costs, making them accessible for startups or companies with limited budgets. Ultimately, the choice between automatic and manual winding machines should reflect the specific requirements of the production process, including volume, precision, and budget considerations.

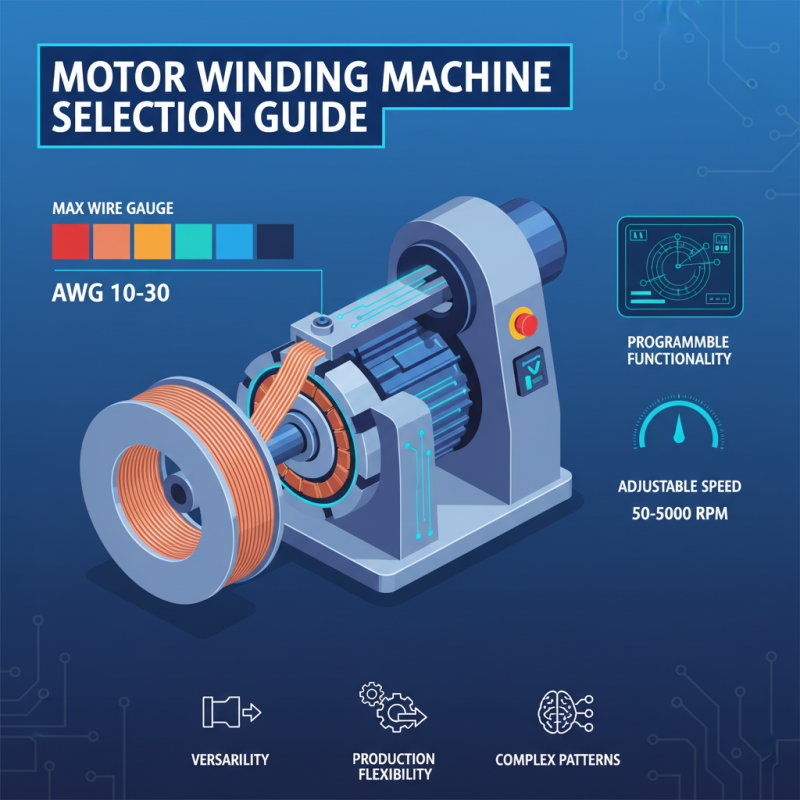

Key Specifications to Consider When Selecting a Motor Winding Machine

When selecting a motor winding machine, it is crucial to focus on key specifications that align with your operational needs. One of the most important aspects to consider is the machine’s winding capacity, which includes the maximum wire gauge and the size of the wires it can handle. This specification directly affects the versatility of the machine, determining its ability to accommodate various motor types and sizes. Additionally, the winding machine should have adjustable winding speeds and programmable functionality, allowing for flexibility in production and the capability to create complex winding patterns.

Another critical specification is the machine’s control system, which can significantly impact efficiency and precision. Look for machines equipped with advanced control interfaces that enable easy adjustments and monitoring of winding parameters. Features such as automated wire feeding and tension control are essential for maintaining consistent quality in winding processes. Furthermore, examining the level of automation offered by the machine can lead to reduced labor costs and enhanced productivity, making it an essential factor in your selection process.

Understanding the Impact of Winding Speed on Production Efficiency

When selecting a motor winding machine, understanding the winding speed is crucial for enhancing production efficiency. The winding speed directly affects the time taken to complete each winding cycle, which in turn influences overall output. A higher winding speed can significantly reduce manufacturing time, allowing for increased production volumes and a faster turnaround on projects. However, it’s important to note that achieving optimal speed requires balancing it with the quality of the windings. Excessive speeds can lead to mistakes, such as misalignment or excessive tension, which can compromise the integrity of the windings and potentially increase waste.

Moreover, different applications and materials require varying winding speeds for optimal results. For instance, delicate wires might necessitate slower speeds to prevent damage, while robust materials may allow for quicker operation. By understanding the specific needs of the application, operators can select a motor winding machine that not only meets their speed requirements but also maintains the quality of the final product. Ultimately, investing in a machine that offers adjustable winding speeds can provide flexibility in production processes, catering to diverse projects and enhancing operational efficiency.

Cost-Benefit Analysis for Investing in Advanced Winding Technology

When investing in a motor winding machine, a thorough cost-benefit analysis is essential to ensure you are making a wise choice for your needs. According to a recent industry report from ResearchAndMarkets, advanced winding technology can provide a return on investment (ROI) of up to 25% over a five-year period. This figure highlights the financial advantages of opting for state-of-the-art machines, which not only enhance precision and efficiency but also reduce material waste and labor costs.

Tips for choosing the right motor winding machine include assessing your production volume and specific design requirements. Higher-end machines may offer features like automated winding settings and advanced diagnostics, but if your production demands are modest, a more basic model might suffice. Additionally, consider the maintenance costs and technical support services provided by the manufacturer, as effective upkeep can significantly prolong the life of your equipment and minimize downtime.

Ultimately, investing in advanced winding technology should align with your business objectives. According to a study conducted by the International Electrotechnical Commission, manufacturers that have upgraded to automated winding systems reported a 30% increase in output efficiency. This kind of improvement can make a significant difference in meeting customer demands while maintaining competitive pricing in the market.

Industry Standards and Compliance Requirements for Winding Machines

When selecting a motor winding machine, understanding industry standards and compliance requirements is crucial for ensuring quality and safety. The International Electrotechnical Commission (IEC) outlines specific performance criteria in standards such as IEC 60034, which emphasizes efficiency and reliability in electric machines. Adhering to these standards not only guarantees compliance but also enhances the machine's performance, leading to longer operational lifespans and reduced maintenance costs.

Moreover, compliance with safety standards like ISO 9001 can significantly impact the manufacturing process. This certification ensures that companies implement a robust quality management system, which is vital for minimizing defects in winding operations. A report from the National Electrical Manufacturers Association (NEMA) indicates that companies adhering to such standards experience a reduction in operational risk by up to 30%. This compliance not only protects the workforce but also ensures that the end product meets stringent industry requirements, fostering trust and reliability among customers. Choosing a winding machine that meets these standards ultimately leads to optimized production processes and enhances overall business efficiency.

Related Posts

-

How to Choose the Best Automatic Coil Winding Machine for Your Business Needs

-

10 Best Motor Winding Coil Machines for Efficient Production in 2023

-

Top 5 Motor Stator Winding Machines for Efficient Coil Production

-

5 Essential Tips for Choosing the Right Wire Winding Machine: Boost Efficiency by 30%

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

Top 10 Spindle Winding Machines for Efficient Production in 2023