Essential Tips for Choosing the Best Motor Coil Winding Machine

In the world of electric motor manufacturing, the precision and efficiency of the motor coil winding machine are paramount. Renowned industry expert Dr. John Peterson once remarked, "Investing in the right motor coil winding machine can significantly enhance production quality and reduce operational costs." With the ever-evolving technology in coil winding, manufacturers must be discerning in their choice of equipment to stay competitive in the market.

Selecting an appropriate motor coil winding machine involves several critical factors, including winding speed, accuracy, and ease of use. The right machine not only increases throughput but also ensures the consistency needed for high-performance motor applications. As the demand for electric motors continues to grow, understanding the nuances of these machines becomes increasingly important for manufacturers aiming for excellence.

In navigating the landscape of motor coil winding machines, it is essential to consider the specific needs of your production line. With the right insights and guidance, organizations can make informed decisions that will lead to long-term success and improved operational efficiency.

Understanding the Basics of Motor Coil Winding Machines

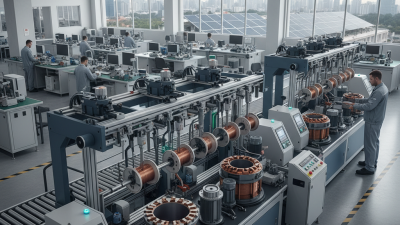

Motor coil winding machines are crucial for the manufacturing of electric motors, serving as the backbone of various industries including automotive, aerospace, and renewable energy. To understand the significance of these machines, it is essential to grasp the basic principles behind their operation. Coil winding is a process that involves wrapping insulated wire around a magnetic core, which is pivotal for creating electromagnets that generate motion or energy. According to a recent industry analysis by Markets and Markets, the global market for motor winding machines is anticipated to reach $1.5 billion by 2026, indicating a strong demand driven by advancements in motor technology and automation.

When selecting a motor coil winding machine, manufacturers must consider several key factors, including precision, speed, and versatility. Precision is vital in ensuring that the coils are wound accurately, reducing the risk of malfunctions and enhancing motor efficiency. Data from the International Electrotechnical Commission highlights that even a slight deviation in winding parameters can lead to a 10% drop in motor performance. Additionally, the speed of a winding machine impacts overall productivity; high-speed machines can significantly decrease manufacturing time, enabling faster response to market demands. Furthermore, flexibility in winding configurations can allow manufacturers to adapt quickly to different motor designs, which is increasingly important in a rapidly evolving technological landscape.

Key Features to Look for in a Coil Winding Machine

When selecting a coil winding machine, it's essential to focus on several key features that can significantly impact the efficiency and quality of your winding process. One of the first features to consider is the machine's versatility. Look for a machine that can handle a variety of wire sizes and types, allowing you to adapt to different projects without investing in multiple machines. This flexibility not only saves costs but also time, making it easier to cater to diverse requirements.

Another critical feature is the control system. A user-friendly interface with precise controls can enhance the winding process. Machines that offer programmable settings allow you to replicate specific winding patterns consistently, ensuring quality and uniformity in your products. Additionally, consider machines that come with advanced monitoring systems, which can provide real-time feedback on winding parameters, ensuring that any issues are promptly addressed.

Tips for maximizing your selection process include assessing the machine's build quality and reliability. A sturdy construction not only translates to durability but also helps minimize vibration, which can affect winding quality. Moreover, ensure that the manufacturer offers adequate support and resources, such as training and manuals, to help you get the most out of your investment. A combination of these features will guide you in choosing the best coil winding machine suited for your specific needs.

Evaluating Different Types of Winding Technologies

When selecting the best motor coil winding machine, it's crucial to evaluate the various winding technologies available. Different methods, such as automatic and manual winding, offer distinct advantages depending on the scale and complexity of the projects you undertake. Automatic machines provide consistency and speed, making them ideal for high-volume production, while manual winding allows for more intricate designs and flexibility in small batches.

Tips for choosing the right winding technology include assessing the specifications of your projects, such as coil size and material type. Understanding your production needs will influence whether you opt for a precision winding machine, capable of handling tight tolerances, or a more versatile model suited for diverse applications. Additionally, consider the learning curve associated with each technology, as some machines may require specialized training to operate efficiently.

Integrating modern winding technologies can enhance productivity and quality. For instance, machines equipped with advanced software can optimize the winding process, ensuring accurate coil formation. Furthermore, investing in machines that allow for easy adjustments will save time and resources, providing a competitive edge in the manufacturing sector. Ultimately, aligning the winding technology with your specific requirements is essential for achieving optimal performance and output.

Essential Tips for Choosing the Best Motor Coil Winding Machine

| Winding Technology | Advantages | Disadvantages | Best Use Cases |

|---|---|---|---|

| Manual Winding | Cost-effective, flexible for custom designs | Time-consuming, requires skilled labor | Small batches, prototypes |

| Automatic Winding | High precision, faster production rates | Higher initial investment, less flexibility | Large scale production |

| Induction Winding | Improved efficiency, reduced heat generation | Complex setup, requires specialized equipment | High-performance applications |

| Robotic Winding | Highly consistent output, ideal for automation | Very high cost, requires significant setup time | Mass manufacturing in automated environments |

| CNC Winding | Precise control over parameters, versatile | Requires programming knowledge, high initial cost | Custom applications with complex winding requirements |

Assessing the Importance of Machine Durability and Reliability

When selecting a motor coil winding machine, the durability and reliability of the machine should be a primary consideration. A machine that can withstand rigorous operation not only enhances productivity but also minimizes downtime and repair costs. Look for machines constructed from high-quality materials and designed with robust engineering principles. A reliable machine should also be able to handle varied workloads without compromising performance over time.

One of the essential tips for choosing the right machine is to evaluate its maintenance needs. A machine that requires frequent repairs can disrupt your production process. Ensure that the machine has easy access for maintenance and comes with clear guidelines for routine checks. Investing in a machine with a reputation for longevity will pay off in the long run as it ensures consistent output and less risk of unexpected failures.

Additionally, consider the machine's capabilities in adapting to future needs. As technology evolves, your production demands may change, and a flexible system can provide a significant advantage. Machines equipped with advanced features like programmable winding patterns or adjustable settings offer more versatility. Thus, choosing a durable and reliable machine not only safeguards your current operations but also prepares you for future challenges in coil winding production.

Budget Considerations: Finding Balance Between Cost and Quality

When selecting a motor coil winding machine, budget considerations play a critical role in achieving the right balance between cost and quality. According to a report by MarketsandMarkets, the global market for coil winding machines is anticipated to grow at a CAGR of 5.4% from 2021 to 2026, driven by increasing automation in manufacturing processes. Businesses must understand that investing in a high-quality machine may incur higher upfront costs, but this can lead to significant long-term savings through improved efficiency and reduced maintenance costs.

When assessing your budget, it’s important to evaluate your production needs and projected volume. For instance, if your operation requires high precision and frequent use, opting for a more robust model could be beneficial despite its higher initial price. Additionally, consider the total cost of ownership, which includes not only the purchase price but also energy consumption, operational costs, and potential downtime.

Tip 1: Always compare the specifications of various machines to ensure they meet the demands of your application while staying within your financial parameters.

Tip 2: Explore financing options that can alleviate the financial burden while allowing you to invest in quality equipment.

Tip 3: Don’t overlook the importance of customer support and warranty options, which can enhance the value of your investment significantly. By making informed choices, you can strike a balance that ensures you invest wisely in the future of your manufacturing operations.

Related Posts

-

Top 2025 Coil Winding Machines Features Benefits and Buying Guide

-

Essential Tips for Choosing the Right Motor Winding Machine for Your Needs

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

2025 Top 5 Used Coil Winding Machines You Need for Your Business

-

How to Choose the Best Programmable Coil Winding Machine for Your Needs

-

What is a Coiling Machine and How Does it Work for Your Projects