Top 10 Spindle Winding Machines for Efficient Production in 2023

In the fast-paced manufacturing landscape of 2023, the relevance of spindle winding machines cannot be overstated. As industries strive for enhanced productivity and efficiency, these machines have emerged as critical tools in the production process. According to a recent industry report, the global market for winding machines is projected to grow at a CAGR of 5.1% over the next five years, underscoring the increasing demand for advanced winding solutions. This growth is driven by innovations in automation and technology, allowing manufacturers to optimize their production lines and reduce operational costs significantly.

Spindle winding machines, with their precision and reliability, play a pivotal role in various sectors, from textiles to electronics. With advancements in design and engineering, these machines now offer greater flexibility and performance, enabling businesses to meet the evolving demands of consumers while maintaining high-quality standards. As manufacturers continue to integrate smart technologies into their operations, the efficiency gains realized through modern spindle winding machines are set to redefine production capabilities across numerous industries. This article highlights the top 10 spindle winding machines available in 2023, providing insights into their features and benefits, and illustrating how they contribute to efficient production practices.

Overview of Spindle Winding Machines in Modern Manufacturing

In the realm of modern manufacturing, spindle winding machines have emerged as pivotal tools, optimizing production processes across various industries. These machines facilitate the winding of materials around spools or drums, ensuring precision and consistency in the final product. With advancements in technology, contemporary spindle winding machines incorporate features such as automation, enhanced speed, and precise tension control, making them indispensable for manufacturers aiming to streamline operations and reduce waste.

To maximize the efficiency of spindle winding machines, it's essential to consider a few tips. First, regular maintenance of the machines can significantly enhance their performance and longevity. Keeping components in good condition helps maintain optimal tension and minimizes the chances of defects. Second, investing in training programs for operators ensures that they are proficient in using the machines, which can lead to improved production rates and reduced operational errors. Lastly, integrating data analytics into the winding process can provide insights into performance metrics, enabling manufacturers to make informed decisions and adjustments on the fly.

Overall, the role of spindle winding machines in modern manufacturing cannot be overstated. By adopting the latest advancements and following best practices, manufacturers can ensure that their production lines are running efficiently, ultimately leading to better product quality and increased profitability.

Top 10 Spindle Winding Machines Production Efficiency Comparison (2023)

This chart illustrates the production efficiency of the top 10 spindle winding machines in 2023, measured in units per hour. It highlights the significant differences in performance, showcasing the machines that lead the market in efficiency.

Key Features to Consider When Selecting a Spindle Winding Machine

When selecting a spindle winding machine, several key features should be prioritized to ensure efficient production. First and foremost, the machine's operational speed is critical. According to a recent industry report by Market Research Future, high-speed winding machines can increase productivity by up to 25%, enabling businesses to meet growing demands in short timeframes. A machine that provides variable speed settings allows manufacturers to tailor operations to different materials and project specifications, enhancing versatility.

Furthermore, the ease of use and maintenance of a spindle winding machine plays a crucial role in minimizing downtime. Machines equipped with intuitive interfaces and automation features can significantly reduce learning curves for operators. According to the International Journal of Advanced Manufacturing Technology, businesses that invest in user-friendly machinery can decrease training time by up to 40%. Additionally, regular maintenance alerts and easy access to components can help prolong the lifespan of the machine, ultimately leading to cost savings over time. Businesses must carefully evaluate these features to make informed decisions that align with their production goals.

Top 10 Spindle Winding Machines for Efficient Production in 2023

| Model | Max Speed (RPM) | Winding Type | Control System | Power Supply (kW) | Weight (kg) |

|---|---|---|---|---|---|

| Model A | 1200 | Conical | PLC | 3.5 | 500 |

| Model B | 1500 | Cylindrical | Touchscreen | 4.0 | 600 |

| Model C | 1000 | Flat | PLC | 3.0 | 550 |

| Model D | 1800 | Custom | Touchscreen | 5.0 | 750 |

| Model E | 1400 | Helical | PLC | 3.8 | 580 |

| Model F | 1600 | Multi-layer | Touchscreen | 4.5 | 700 |

| Model G | 1100 | High Precision | PLC | 3.2 | 530 |

| Model H | 1300 | Standard | Touchscreen | 3.3 | 590 |

| Model I | 1700 | Precision | PLC | 4.2 | 720 |

| Model J | 1900 | Industrial | Touchscreen | 5.5 | 800 |

Top 10 Spindle Winding Machines of 2023: A Comparative Analysis

The selection of the right spindle winding machine can significantly impact production efficiency and overall output quality. In 2023, various models have emerged that stand out due to their advanced technology and user-friendly features. This comparative analysis highlights the key aspects of these machines, including their winding speed, precision, and flexibility in handling different materials.

One of the most critical factors to consider when evaluating spindle winding machines is their ability to adapt to various production demands. Many machines now offer programmable settings, allowing operators to easily switch between different winding patterns and parameters. Additionally, enhanced sensors and control systems enable real-time monitoring of the winding process, ensuring that any inconsistencies can be immediately addressed. As manufacturers strive for increased automation, some of these machines also feature integrated software that can streamline the production workflow, making them suitable for both small-scale operations and large manufacturing environments.

Overall, the advancements in spindle winding machinery in 2023 reveal a trend toward innovation and efficiency. The comparative analysis of these top machines not only showcases their technical capabilities but also emphasizes their importance in enhancing production lines. As companies aim to meet growing consumer demands, investing in the right spindle winding machine can be a crucial step toward optimizing manufacturing processes.

Benefits of Upgrading to Advanced Spindle Winding Technology

Upgrading to advanced spindle winding technology offers a multitude of benefits that can significantly enhance production efficiency. Modern spindle winding machines are designed with precision and automation in mind, allowing manufacturers to achieve higher accuracy in winding processes. This increased precision reduces material waste and improves the overall quality of the final products. Advanced systems can also handle a wider range of materials and winding configurations, providing flexibility that is essential in today’s fast-paced manufacturing environment.

Moreover, these upgraded technologies often feature enhanced data analytics capabilities, enabling real-time monitoring and adjustment of the winding process. This not only leads to improved operational efficiency but also minimizes downtime caused by manual adjustments or machine malfunctions. In addition, the integration of user-friendly interfaces simplifies the training process for operators, reducing the learning curve and allowing for quicker adaptation to new technologies. Overall, investing in advanced spindle winding machines is a strategic move that can drive productivity, streamline operations, and position manufacturers for future growth and competitiveness.

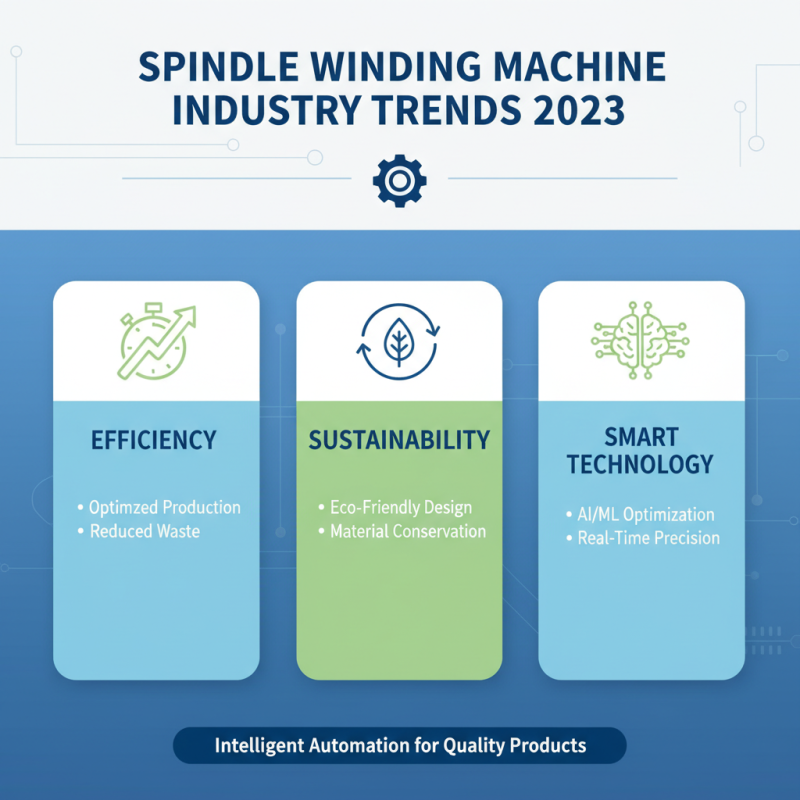

Future Trends in Spindle Winding Machine Development and Efficiency

In 2023, the spindle winding machine industry is witnessing transformative trends that emphasize not only efficiency but also sustainability and smart technology integration. As manufacturers seek to enhance production capabilities, innovations in machine design and functionality are becoming increasingly sophisticated. For instance, the adoption of artificial intelligence and machine learning algorithms allows these machines to optimize winding processes in real time, minimizing waste and increasing the precision of outputs. This shift toward intelligent automation is not just about increasing speed but also about improving the quality of the final product.

Future developments in spindle winding machines are also heavily leaning towards energy efficiency and sustainable practices. Manufacturers are now focusing on reducing the carbon footprint of their operations by incorporating eco-friendly materials and technologies that consume less energy. Additionally, the integration of IoT (Internet of Things) allows for better monitoring and control of the production environment, facilitating predictive maintenance and reducing downtime. As the industry evolves, these advancements will not only enhance production efficiency but also ensure that businesses remain competitive in a rapidly changing market landscape.

Related Posts

-

2025 Top Spindle Winding Machine Innovations and Buying Guide

-

10 Best Motor Winding Coil Machines for Efficient Production in 2023

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide

-

5 Essential Tips for Choosing the Right Wire Winding Machine: Boost Efficiency by 30%

-

What is Automated Machine Learning Its Impact on Industry Growth and Efficiency

-

How to Choose the Best Automatic Coil Winding Machine for Your Business Needs