Revolutionizing Efficiency How Motor Winding Automatic Machines Transform Manufacturing

In the ever-evolving landscape of manufacturing, the advent of the motor winding automatic machine has brought about a significant transformation in operational efficiency. As industry expert Dr. Emily Carter, a leading authority in automation technologies, aptly states, “The integration of motor winding automatic machines not only enhances precision but also accelerates production time, ultimately redefining the standards of quality in manufacturing.”

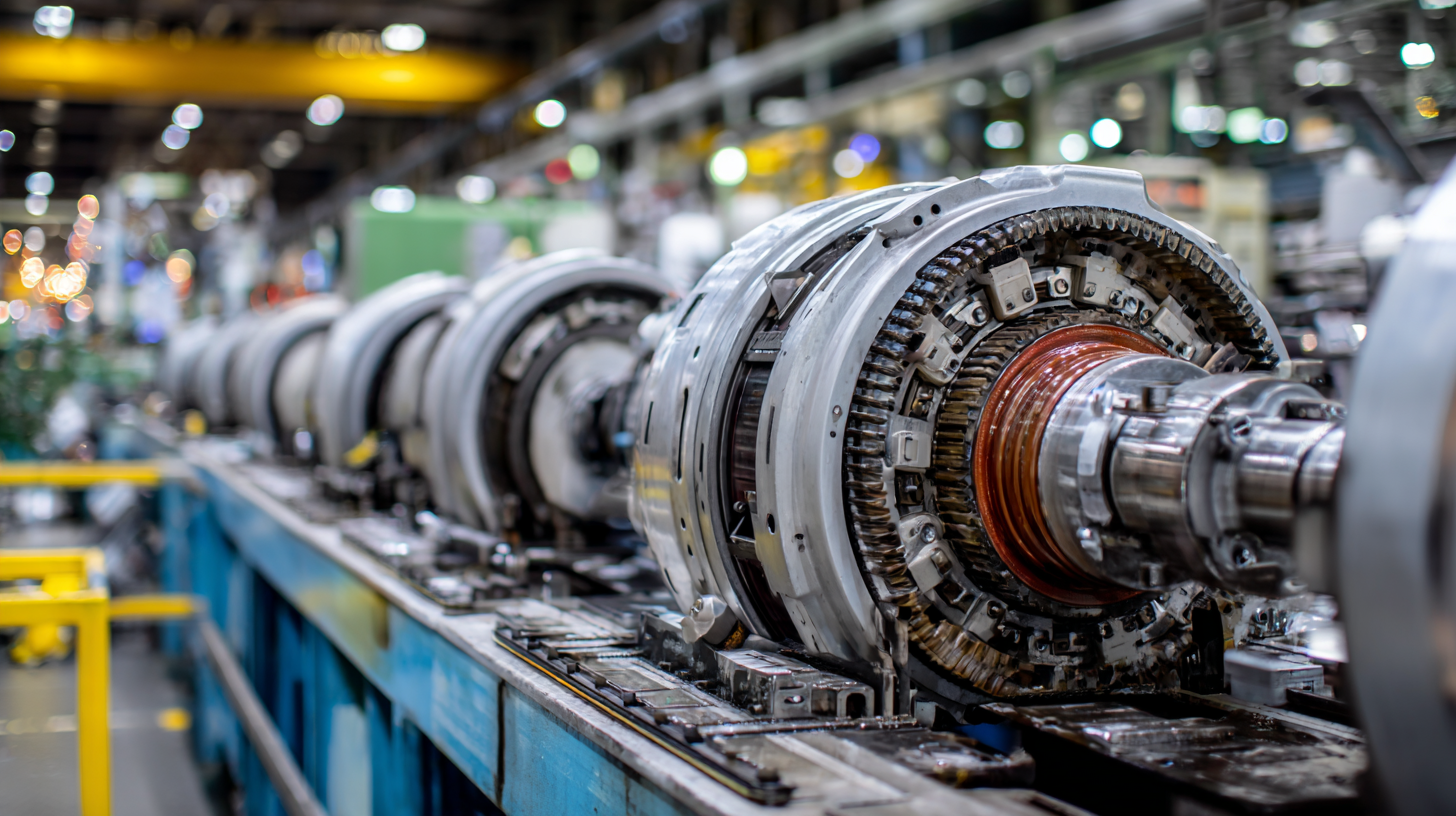

This revolutionary technology streamlines the winding process of electric motors, a critical component in numerous applications, from household appliances to large industrial machinery. By minimizing human error and maximizing output speed, manufacturers are now equipped to meet rising consumer demands while maintaining rigorous quality control.

Moreover, the adoption of motor winding automatic machines signifies a shift towards smarter manufacturing practices. By employing sophisticated algorithms and real-time monitoring, these machines provide invaluable data that can drive continuous improvement across production lines. As we delve deeper into the intricacies of this technology, we will explore how motor winding automatic machines are not just enhancing efficiency, but are also paving the way for a new era of innovation in the manufacturing sector.

Enhancing Production Speed Through Motor Winding Automation

In the competitive landscape of modern manufacturing, enhancing production speed is paramount. Motor winding automation is at the forefront of this revolution, offering companies the capability to significantly increase their output. By integrating automatic machines into the production line, manufacturers can minimize human error and streamline processes, leading to remarkable efficiency gains. These sophisticated machines not only wind motors faster but also maintain consistent quality, ensuring that every product meets stringent standards.

**Tip:** To maximize the benefits of motor winding automation, consider investing in training for your team. Familiarizing them with the latest technologies can help unlock the full potential of these machines and improve overall operational efficiency.

The shift towards automated motor winding also allows manufacturers to allocate resources more strategically. With machines handling repetitive tasks, human operators can focus on more complex responsibilities that require critical thinking and creativity. This shift not only boosts productivity but also fosters innovation, as teams are freed from mundane duties.

**Tip:** Regular maintenance of automatic machines is essential for sustaining high production speed. Implement a scheduled maintenance program to prevent downtime and keep your machinery in optimal condition.

Revolutionizing Efficiency: Impact of Motor Winding Automation on Production Speed

This chart illustrates the production speed improvement in manufacturing processes before and after implementing motor winding automation. The data represents the average production speed (units per hour) across typical manufacturing operations.

Key Features of Cutting-Edge Motor Winding Machines

Cutting-edge motor winding machines are revolutionizing manufacturing processes with their innovative features that significantly enhance efficiency and precision. These advanced tools are designed to streamline the production of coils, which are vital components in various electrical devices such as transformers and motors. The latest machines incorporate automation technology that allows for high-speed operation, reducing production time while maintaining accuracy. Additionally, enhanced control systems enable manufacturers to optimize winding configurations and minimize waste, leading to cost savings and improved product quality.

The demand for such precision coil winding machines is rapidly increasing, driven by the growing need for high-quality electrical components in various industries. Advanced motor winding machines often feature real-time monitoring capabilities, ensuring operational efficiency and facilitating quick adjustments during production. Furthermore, innovations like integrated robot solutions are emerging, providing solutions to further automate the winding process, thus meeting the ever-evolving standards of modern manufacturing. These advancements not only boost productivity but also position manufacturers to better adapt to the dynamic market needs.

Revolutionizing Efficiency: How Motor Winding Automatic Machines Transform Manufacturing

| Feature | Description | Benefits |

|---|---|---|

| Automatic Coil Winding | Utilizes programmable logic controllers to manage winding processes. | Increases precision and consistency in production. |

| Real-Time Monitoring | Provides live data on machine performance and output. | Allows for immediate adjustments to optimize production rates. |

| Flexible Configurations | Can be adjusted for various motor sizes and types. | Enhances versatility in manufacturing setups. |

| Safety Features | Equipped with emergency stop mechanisms and safety guards. | Protects workers and reduces risk of accidents. |

| Energy Efficiency | Optimizes energy consumption during operations. | Reduces operating costs and environmental impact. |

Cost Savings and ROI from Automating Manufacturing Processes

The advancement of motor winding automatic machines has significantly reshaped manufacturing processes, leading to substantial cost savings and improved return on investment (ROI). By automating routine tasks, manufacturers can minimize labor costs, reduce production errors, and enhance operational speed. These machines ensure consistent quality and precision in winding, which is crucial for producing effective electrical motors. This high level of automation not only streamlines production workflows but also allows companies to allocate their workforce to more strategic roles, enhancing overall productivity.

Moreover, the upfront investment in motor winding automation technology is often recouped quickly through decreased operational expenses and increased output. Companies can expect to see a positive ROI within a relatively short timeframe as efficiency rises and scrap rates decline. As demand for high-quality electrical motors grows, the ability to scale production without a proportional increase in costs becomes paramount. Thus, embracing motor winding automatic machines is not just a trend; it is a strategic move that positions manufacturers for long-term success in an increasingly competitive landscape.

Integrating Technology for Seamless Motor Winding Operations

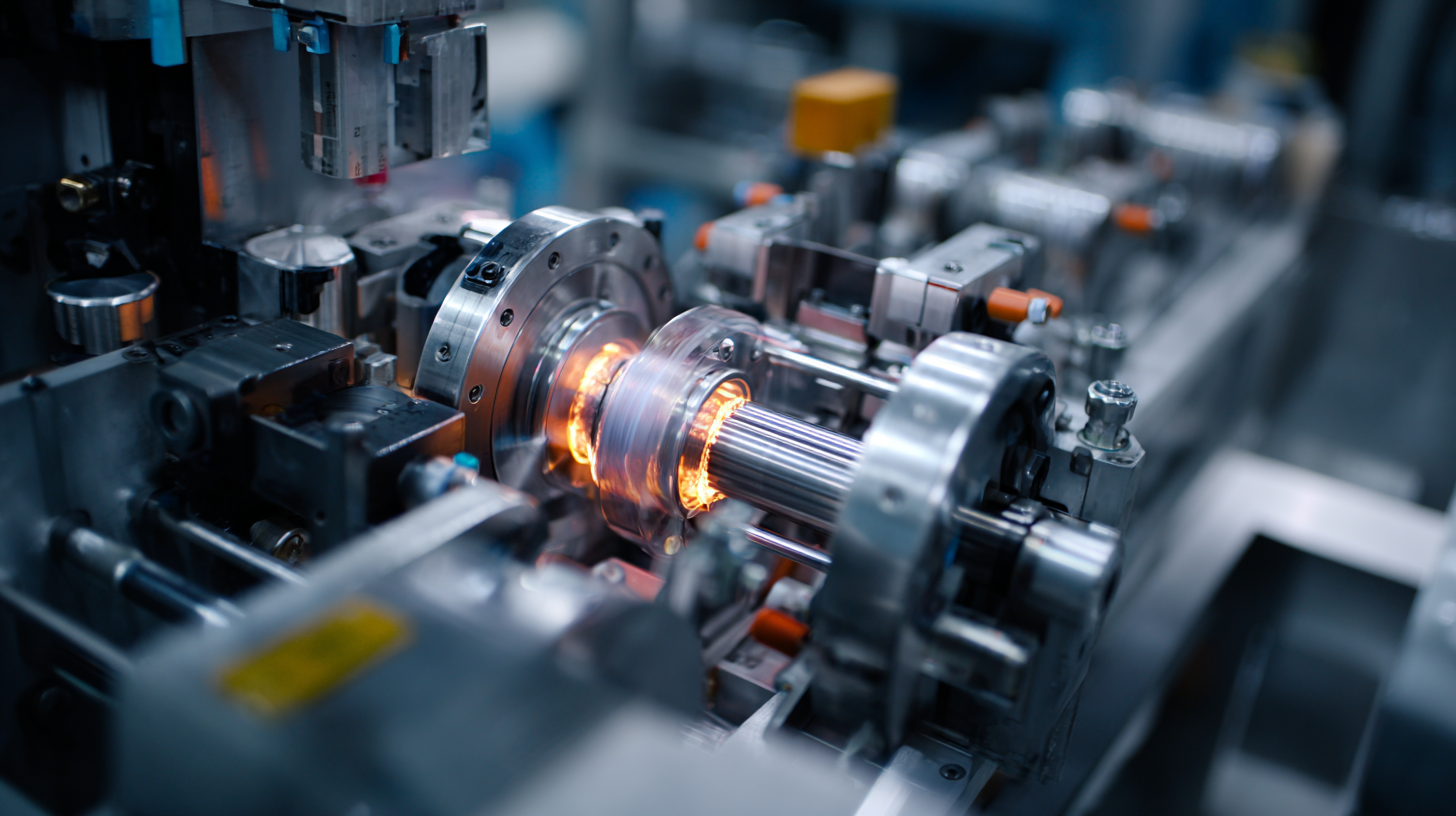

The integration of advanced technology in motor winding operations is paving the way for unprecedented efficiency and precision in manufacturing. By employing automatic machines for winding, manufacturers can significantly reduce manual labor while enhancing the quality of the products. These machines are equipped with sophisticated software that ensures each winding is executed with exact specifications, minimizing errors that could lead to costly revisions and downtime. The seamless operation facilitated by these technologies not only streamlines production but also aids in meeting the increasing demands of the market.

The integration of advanced technology in motor winding operations is paving the way for unprecedented efficiency and precision in manufacturing. By employing automatic machines for winding, manufacturers can significantly reduce manual labor while enhancing the quality of the products. These machines are equipped with sophisticated software that ensures each winding is executed with exact specifications, minimizing errors that could lead to costly revisions and downtime. The seamless operation facilitated by these technologies not only streamlines production but also aids in meeting the increasing demands of the market.

Tips: When implementing motor winding automatic machines, ensure that the software is regularly updated to leverage the latest features. Training staff on how to operate and troubleshoot these machines can further optimize productivity and maintain the machinery’s effectiveness.

Moreover, the use of automated winding solutions allows for greater flexibility in production schedules. Manufacturers can easily adjust the winding parameters to accommodate different motor sizes and specifications without the need for extensive reconfiguration. This adaptability not only shortens lead times but also enables producers to respond swiftly to changing market demands.

Tips: Conduct regular maintenance checks on the automatic winding machines to prevent unexpected breakdowns. Implementing a preventive maintenance routine can enhance machine longevity and maintain consistent production quality.

Future Trends in Motor Winding Technology and Automation

The future of motor winding technology and automation is poised for groundbreaking advancements that promise to enhance efficiency and precision in manufacturing processes. As industries increasingly embrace automation, we see a shift towards smart machines capable of self-learning and real-time adjustments. This not only speeds up production but also significantly reduces errors, ensuring that each motor winding meets the highest standards of quality. Emerging technologies, such as AI and IoT, are becoming integral in monitoring machine performance and predicting maintenance, which will further streamline operations.

**Tip:** To stay ahead in this rapidly evolving landscape, manufacturers should invest in research and development for automation technologies. Collaborating with tech innovators can provide valuable insights into the latest trends and tools.

Another critical trend is the move towards sustainability in motor winding processes. As environmental concerns grow, manufacturers are increasingly focusing on energy-efficient machines and eco-friendly materials. Automated winding machines can optimize energy consumption and minimize waste by implementing precise control systems. This not only benefits the planet but also enhances the bottom line by reducing operational costs.

**Tip:** Regularly assess your production processes for sustainability opportunities. Consider implementing energy audits to identify areas where efficiency can be improved, thus aligning with both economic and environmental goals.