What is a Coiling Machine and How Does it Work for Your Projects

In the realm of manufacturing and crafting, the coiling machine plays a pivotal role in optimizing production efficiency and enhancing creative designs. According to industry expert Dr. Emily Chen, a well-known figure in mechanical engineering, "A coiling machine not only automates the process of wire formation but also significantly reduces material waste, leading to more sustainable practices." This underscores the importance of modern technology in transforming traditional manufacturing methods.

Coiling machines are designed to produce spiral-shaped components, utilizing advanced mechanisms to ensure precision and speed. As projects demand greater accuracy and complexity, understanding how a coiling machine operates becomes essential for professionals seeking to improve their productivity. This introduction will delve into the operational principles of coiling machines, their applications across various industries, and the benefits they offer to enhance your projects.

By exploring the intricacies of coiling machines, we unveil their significance in introducing innovative solutions, ensuring quality output, and promoting efficiency across diverse sectors. The synergy between traditional craftsmanship and modern machinery is reshaping the manufacturing landscape, making it imperative for industry stakeholders to stay informed about these advancements.

What is a Coiling Machine? Definition and Overview

A coiling machine is a specialized piece of equipment designed to manage the complex process of winding materials into coils or rolls. It is commonly used in various industries, including manufacturing, textile, and electronics, where precise and efficient coil formation is essential for production. The machine operates by feeding a material, such as wire, fiber, or ribbon, through a series of rollers and guides that facilitate its turning around a central axis. This integration of mechanical components ensures uniform tension and consistency, resulting in high-quality coiled products.

The functionality of a coiling machine hinges on its ability to adapt to different material dimensions and coiling requirements. Operators can adjust settings such as coil diameter, width, and layering, which makes the coiling process highly flexible. This adaptability not only enhances production efficiency but also allows for customization, catering to specific project needs. Furthermore, modern coiling machines often come equipped with advanced automation features, which streamline workflows and reduce manual labor. By automating the coiling process, businesses can achieve higher output while minimizing errors associated with manual coiling.

Coiling Machine Usage in Various Industries

Types of Coiling Machines and Their Applications

Coiling machines come in various types, each designed for specific applications that enhance productivity and efficiency in different industries. One common type is the automatic wire coiling machine, which is widely used in manufacturing processes where precision is key. These machines can rapidly coil wires to precise diameters, reducing labor costs and minimizing waste. Additionally, manual coiling machines are preferable in smaller operations where flexibility is essential, allowing users to adjust coil sizes and shapes based on their project requirements.

Another category includes plastic coiling machines, favored in industries that require flexible plastic tubing and components. These coilers can create customized shapes and sizes for items such as electrical conduits or medical devices, thereby expanding creative possibilities for engineers and designers. Furthermore, industrial coiling machines are specifically built to handle heavy-duty materials, such as cables and chains, making them indispensable in construction and heavy manufacturing settings.

Tips: When selecting a coiling machine, consider the nature of your projects and the materials you'll be working with. Look for machines that offer adjustable features to accommodate a range of project sizes. Regular maintenance of your coiling machine can also extend its lifespan, ensuring consistent quality in your production processes.

How Coiling Machines Function: A Step-by-Step Explanation

Coiling machines are essential tools in various industries, facilitating the winding of materials into coils for easier handling and storage. The basic operation of a coiling machine begins with feeding the material into the system. The machine then employs a rotating spindle or drum that winds the material around itself, ensuring consistent tension and uniformity in the coils produced. As the process continues, sensors and control systems monitor the winding speed and quality, allowing adjustments to maintain optimal performance.

Tips for effective use of coiling machines include ensuring proper material alignment before starting the machine to avoid jams or uneven coils. Regular maintenance of the machine’s components, such as the spindle and drive systems, helps in prolonging its lifespan and enhancing its efficiency. Additionally, operators should familiarize themselves with the machine’s controls and settings to achieve better results tailored to specific project requirements.

Furthermore, keeping the workspace clean and organized can significantly reduce the risk of accidents or material contamination. It's also beneficial to conduct trial runs with small quantities of material to refine the machine settings before proceeding with larger batches. By understanding how coiling machines function, users can maximize their productivity and the quality of their final products.

What is a Coiling Machine and How Does it Work for Your Projects - How Coiling Machines Function: A Step-by-Step Explanation

| Dimension | Description | Importance |

|---|---|---|

| Wire Diameter | The thickness of the wire being used in the coiling process. | Affects the strength and flexibility of the final product. |

| Coiling Speed | The rate at which the machine can coil the wire. | Influences production efficiency and output volume. |

| Wire Material | Type of material used (e.g., steel, copper, aluminum). | Determines the application and suitability for projects. |

| Coiling Diameter | The diameter of the coils produced by the machine. | Impacts the design and function of the finished product. |

| Control Mechanism | Technology used to manage the coiling process (e.g., manual, automated). | Affects precision and ease of use. |

| Applications | Common uses for coiling machines in various industries. | Helps in identifying the relevance to specific projects. |

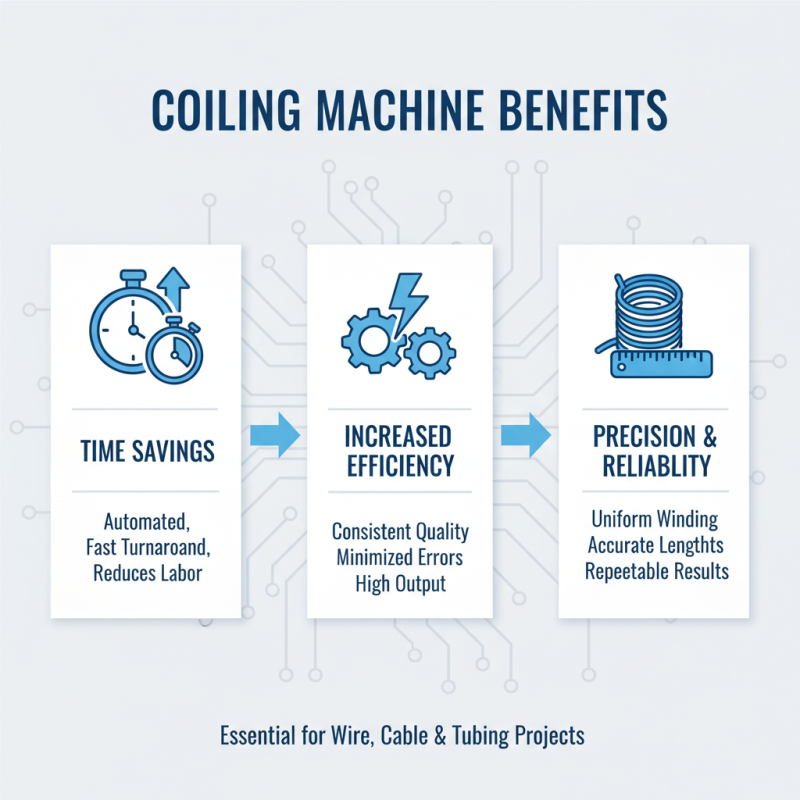

Benefits of Using a Coiling Machine in Projects

A coiling machine is an invaluable tool for various projects, significantly enhancing efficiency and precision in the winding of materials like wire, cable, or tubing. One of the primary benefits of using a coiling machine is the substantial time savings it offers. Manual coiling can be labor-intensive and prone to errors, but a machine ensures consistent quality and a quick turnaround. This is particularly advantageous in industries where deadlines are critical and perfection is paramount.

Additionally, coiling machines provide uniformity in the coil's dimensions, which is crucial for projects requiring exact specifications. This uniformity minimizes waste and maximizes the use of materials, leading to cost-effectiveness in production processes. Furthermore, the reduction in human error translates to fewer defects, enhancing overall project quality.

**Tip:** When using a coiling machine, always make sure to calibrate it according to your project's specifications to achieve the best results. Also, regularly maintain the machine to prevent downtime and ensure smooth operation.

Another notable benefit is the ease of operation these machines provide, allowing even novice users to achieve professional-level results. The automation involved means that projects can scale up without the need for correspondingly higher labor costs.

**Tip:** Familiarize yourself with the machine's settings and features, as understanding its capabilities can help you tailor its use to specific project needs, maximizing efficiency and output.

Maintenance Tips for Coiling Machines to Ensure Longevity

Maintaining a coiling machine is essential to ensure its longevity and optimal performance. Regular inspection and cleaning of the machine's components can prevent dust and debris from accumulating, which could lead to malfunctions or inefficient operation. When cleaning, focus on parts such as the rollers, guides, and any intricate mechanisms that might collect residue. Additionally, lubricating moving parts with the appropriate oils will help reduce friction and wear, extending the life of your machine.

Another critical aspect of maintenance involves monitoring the machine's alignment and tension settings. Regularly check to ensure that components are correctly aligned to prevent uneven wear and possible damage during operation. It's also advisable to conduct routine checks on the machine's electrical systems and safety features to ensure they are functioning correctly. Establishing a consistent maintenance schedule can help identify potential issues early on, allowing for timely repairs and minimizing downtime in your projects.

Related Posts

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

2025 Top 5 Used Coil Winding Machines You Need for Your Business

-

Revolutionizing Efficiency How Motor Winding Automatic Machines Transform Manufacturing

-

How to Choose the Best Automatic Coil Winding Machine for Your Business Needs

-

What is Automated Machine Learning Its Impact on Industry Growth and Efficiency

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide