How to Choose the Best Wire Coil Winding Machine for Your Needs

Choosing the right wire coil winding machine is critical for efficiency and quality. Richard Novak, an industry expert, emphasizes, "Selecting the right machine can make or break your production line." His wisdom resonates in a market filled with options and specifications.

When considering a wire coil winding machine, assess your production volume and goals. Different machines cater to varying needs. Some models focus on speed, while others emphasize precision. It's important to match your machine with your specific requirements. Do you produce small batches or large volumes? The answer influences your choice significantly.

Budget is another vital factor. While high-end machines offer advanced features, they may not be necessary for every business. Balance performance and cost. Remember that investing in a wire coil winding machine is a long-term commitment. Evaluate your options thoroughly to avoid regrets down the road. In this evolving industry, making an informed decision is essential for success.

Understanding the Different Types of Wire Coil Winding Machines

When choosing a wire coil winding machine, it's important to understand the different types available. There are two primary categories: manual and automatic. Manual machines require operators to handle the winding process. This can allow for greater control. However, it may also lead to inconsistencies if the operator lacks experience.

On the other hand, automatic machines can enhance efficiency. They can produce coils with precision and reduce human error. Yet, they tend to be more expensive. It’s essential to consider your budget. Also, think about the production scale needed. Do you need small batches or large volumes? This decision can significantly impact your choice.

Another factor is the type of wire used. Different machines can handle different gauge sizes. Some are designed for fine wire, while others are suited for thicker gauges. Assess your specific requirements carefully. Investing too much in a machine that doesn't meet your needs can be a costly mistake. Inadequate research might lead to regrets down the line.

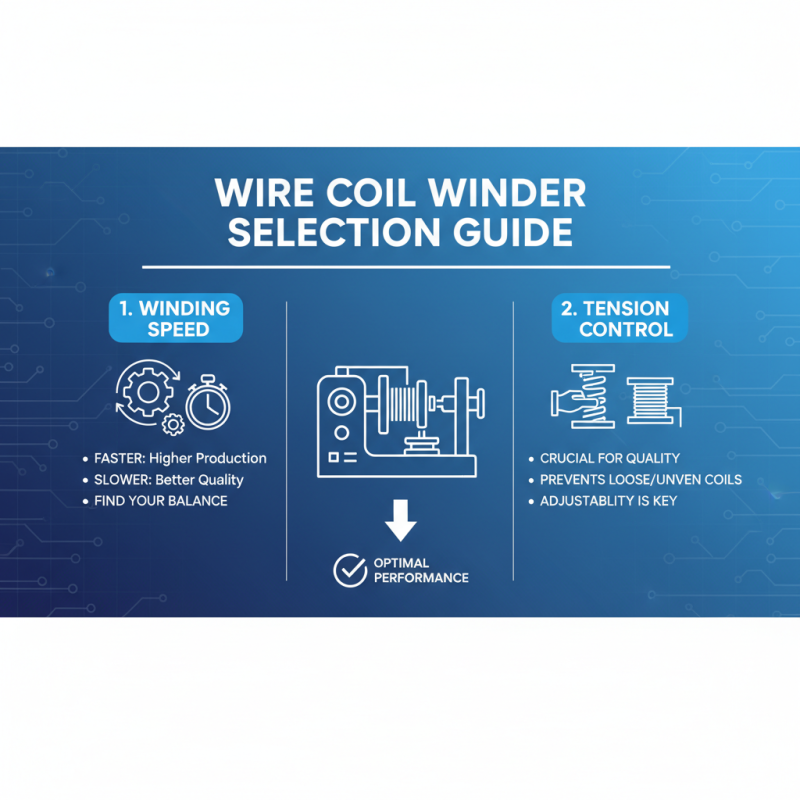

Key Features to Consider When Selecting a Winding Machine

When selecting a wire coil winding machine, key features should guide your decision. Consider the machine's winding speed. A faster machine can boost production rates but may compromise quality. Look for a balance that meets your requirements. The ability to adjust tension is also crucial. Tension directly affects the quality of the winding. Insufficient control can lead to loose or uneven coils, requiring adjustments later.

Another aspect to think about is the machine's build quality. A sturdy design can withstand intensive use, reducing maintenance needs. Pay attention to the type of materials used. Cheaper materials can save money upfront but lead to issues over time. Ease of use is important as well. If the controls aren't user-friendly, it can lead to frustrations during operation. Training employees to use complex machines may become an unexpected burden.

Lastly, compatibility with different wire types is essential. Some machines excel with specific wire gauges or materials. Consider your current and future projects. This foresight can help prevent limitations down the road. Review feedback from existing users to find common pitfalls. Reflect on your specific needs and how they evolve.

Assessing Your Production Needs and Volume Requirements

Choosing the right wire coil winding machine starts with understanding your production needs. Analyze the types of coils you produce. Different applications require different winding techniques. Note the wire types you will be working with. Consider their gauges and materials. Each factor will influence your machine selection.

Next, assess your volume requirements. Will you run small batches or high-volume orders? High-capacity machines work well for larger volumes but may be overkill for small, detailed work. Balance your production speed and accuracy. Sometimes, faster machines sacrifice precision. Is that acceptable for your products? Reflect on your capacity for adjusting workflows. Flexibility in equipment may save you headaches later.

Budgeting and Cost Analysis for Wire Coil Winding Machines

When budgeting for a wire coil winding machine, consider your production needs. Machines come in various price ranges. A more expensive model may not always be the best choice. Assess the features that are essential for your operations, such as speed, accuracy, and ease of use. A detailed cost analysis will help identify potential hidden costs.

Tips: Start by creating a list of must-have features. Compare prices among different suppliers, but remember, low cost doesn’t always mean low quality. Look for reviews or testimonials about the machines you’re considering.

Also, think about the long-term costs. Maintenance and parts can add up. Sometimes a cheaper machine might require more repairs. Reflect on how often you’ll need to use the machine. This can influence your overall budget significantly. Are you planning for large production volumes? Then it might be worth investing in a more robust system.

Tips: Don't hesitate to negotiate with suppliers. Ask about discounts for bulk purchases or service agreements. Keep an eye on market trends, which can affect the prices of machines, ensuring you get the best deal possible.

How to Choose the Best Wire Coil Winding Machine for Your Needs - Budgeting and Cost Analysis for Wire Coil Winding Machines

| Machine Type | Number of Turns | Max Wire Diameter (mm) | Speed (RPM) | Price (USD) |

|---|---|---|---|---|

| Automatic Winder | 1000 | 2.5 | 300 | 2500 |

| Semi-Automatic Winder | 800 | 3.0 | 250 | 1800 |

| Manual Winder | 500 | 4.0 | 150 | 800 |

| CNC Winder | 2000 | 2.0 | 600 | 5000 |

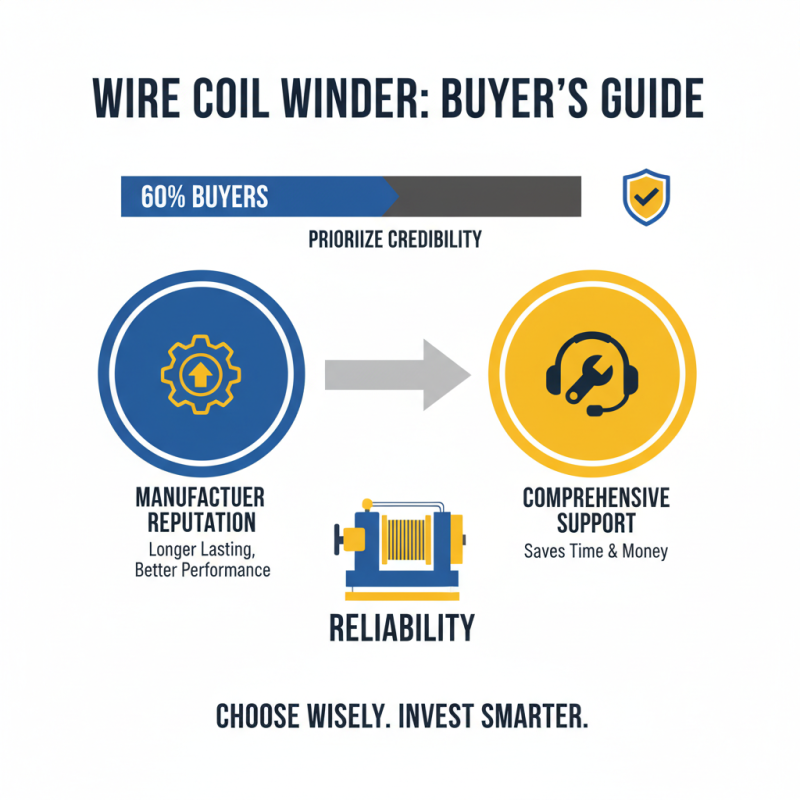

Evaluating Manufacturer Reputation and Customer Support Services

When selecting a wire coil winding machine, evaluating manufacturer reputation and customer support is crucial. Research shows that over 60% of buyers prioritize manufacturer credibility. A reliable machine lasts longer and performs better. The right manufacturer often provides comprehensive support, which can save time and money.

Customer support services can significantly impact a business’s efficiency. Data indicates that 70% of users who experience good support are likely to remain loyal. Timely responses to issues prevent downtime. A manufacturer that offers training and responsive support can lead to a smoother winding process. However, not all manufacturers meet these expectations.

Consider common challenges. Some buyers overlook support during their decision process. If a machine breaks down, weak support can lead to extended outages. Additionally, ensure that the manufacturer has a proven track record. Researching customer reviews often reveals insights about hidden flaws. Performance may not meet initial expectations if support is lacking, revealing an area that needs attention.

Related Posts

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

2025 Top 5 Used Coil Winding Machines You Need for Your Business

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide

-

How to Choose the Best Micro Coil Winding Machine for Your Needs

-

10 Best Motor Winding Coil Machines for Efficient Production in 2023

-

Top 10 Spindle Winding Machines for Efficient Production in 2023