How to Choose the Best Automatic Coil Winding Machine for Your Business Needs

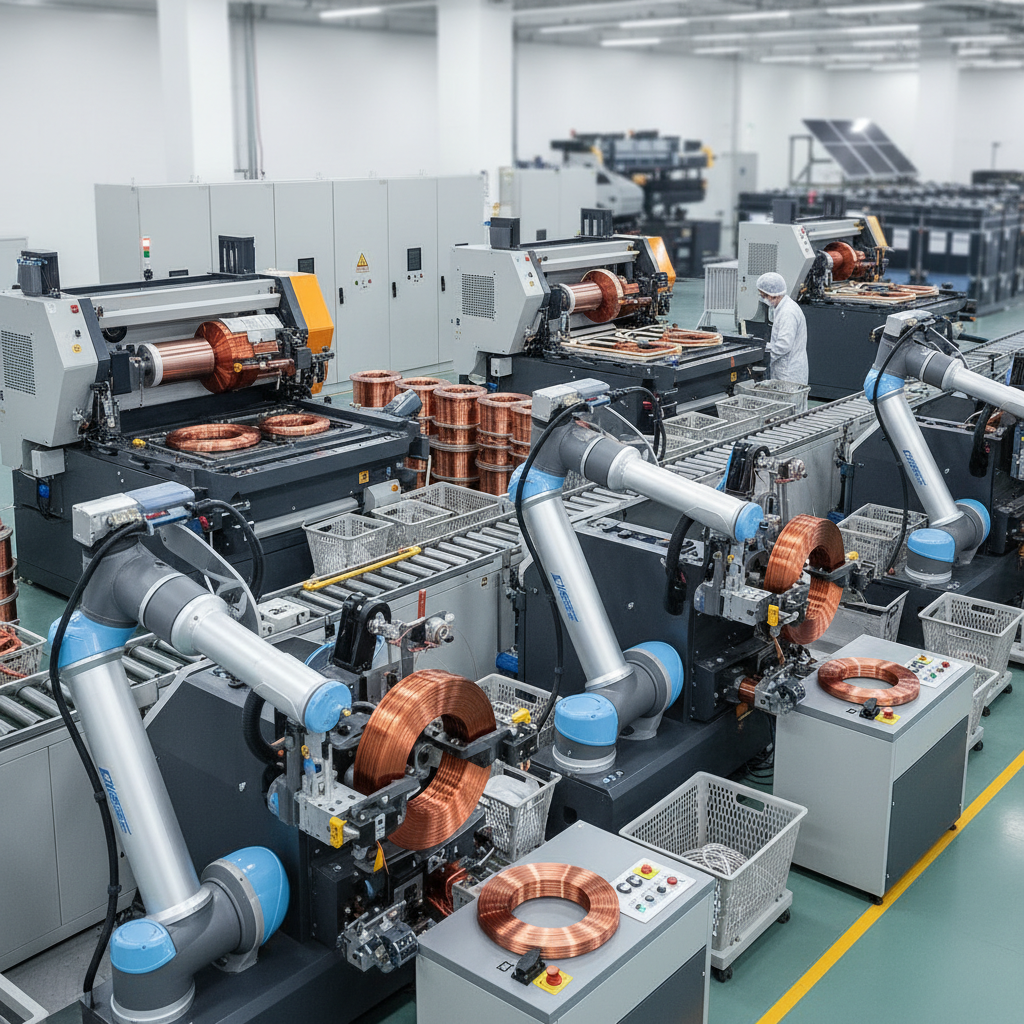

In the rapidly evolving manufacturing landscape, selecting the right equipment is crucial for optimizing production efficiency and quality. Among these tools, the automatic coil winding machine plays a pivotal role, especially in industries such as electronics and automotive. According to industry expert Dr. Emily Hartwell, a leading authority on manufacturing technologies, "Investing in the right automatic coil winding machine not only streamlines operations but also ensures consistent product quality, which is vital for maintaining a competitive edge in today’s market."

As businesses seek to enhance their output, understanding the nuances of selecting the most suitable automatic coil winding machine becomes essential. Factors such as machine specifications, production capacity, and automation features must be carefully assessed to align with specific business needs. This guide aims to provide a comprehensive overview of these considerations, empowering manufacturers to make informed decisions that will ultimately drive growth and innovation within their operations.

As businesses seek to enhance their output, understanding the nuances of selecting the most suitable automatic coil winding machine becomes essential. Factors such as machine specifications, production capacity, and automation features must be carefully assessed to align with specific business needs. This guide aims to provide a comprehensive overview of these considerations, empowering manufacturers to make informed decisions that will ultimately drive growth and innovation within their operations.

In conclusion, as the demand for high-quality coil winding solutions surges, equipping oneself with the right knowledge is imperative. Knowing what to look for in an automatic coil winding machine can significantly influence a company's production capabilities and profitability in the long run.

Understanding Different Types of Automatic Coil Winding Machines for Various Applications

When selecting an automatic coil winding machine, it's essential to understand the different types available and their applications. The three primary categories are toroidal, cylindrical, and flat coil winding machines. According to a report by Grand View Research, the global market for coil winding machines is expected to grow at a CAGR of 6.1% from 2023 to 2030, driven by the increasing demand for electric vehicles and renewable energy systems that require efficient winding processes.

Toroidal winding machines are renowned for their compact design and efficiency, making them ideal for inductors and transformers. In contrast, cylindrical winding machines are favored for their versatility and are commonly used in motors and generators. Flat coil machines, meanwhile, are specifically designed for applications requiring a flat winding configuration, such as in certain types of sensors.

**Tips:** Before making a purchase, consider the machine's winding speed and the maximum wire size it can handle. Additionally, evaluate the machine's compatibility with your production process and the level of automation required. Investing in a machine that offers flexibility can save you from costly upgrades in the future.

Evaluating Key Features to Consider When Selecting a Coil Winding Machine

When selecting the best automatic coil winding machine for your business needs, it’s essential to evaluate several key features that can significantly influence productivity and efficiency. One crucial aspect is the machine's winding speed, which can vary significantly between models. According to a recent industry report by MarketsandMarkets, machines that operate at speeds exceeding 1000 RPM can enhance operational throughput, allowing manufacturers to meet demanding production schedules without compromising quality.

Another vital consideration is the machine’s capability for precision winding. A study published by ResearchAndMarkets highlights that advancements in technology have enabled machines to achieve winding tolerances of less than 1% in many applications. This precision is crucial for industries such as automotive and aerospace, where performance and reliability are paramount. Additionally, features like programmable controls and user-friendly interfaces can reduce setup times and improve overall ease of use, which is especially beneficial for companies looking to minimize training costs and improve workforce efficiency.

Investing in a machine that offers versatility in terms of coil shapes, sizes, and materials can also provide significant long-term benefits. A versatile coil winding machine allows manufacturers to adapt to various customer demands and emerging trends, further enhancing their competitive edge. Understanding these critical factors can facilitate a more informed decision-making process, ultimately contributing to a more efficient and productive operation.

Comparative Analysis of Top Brands in Automatic Coil Winding Machines

When selecting the best automatic coil winding machine for your business, a comparative analysis of top brands can significantly inform your decision. Leading manufacturers such as XYZ Corp, ABC Technologies, and CoilMaster provide distinct features that cater to different production requirements. XYZ Corp is known for its user-friendly interface and rapid setup times, making it ideal for businesses that prioritize efficiency. In contrast, ABC Technologies offers robust machines with high precision, perfect for industries where exact specifications are critical.

Tips: When evaluating these machines, it's vital to consider not only the initial cost but also the overall maintenance and support offered by the brands. A machine that requires minimal downtime can drastically affect your production rates. Additionally, pay attention to the warranty and longevity of the equipment, as investing in a reliable machine can yield greater returns over time.

Moreover, it's essential to assess the scalability of the coil winding machines. For growing businesses, choosing a machine that can easily adapt to increased production demands without significant upgrades is crucial. Compare the technological advancements across brands and select a model that aligns with your long-term business goals.

How to Choose the Best Automatic Coil Winding Machine for Your Business Needs

| Feature | Machine A | Machine B | Machine C | Machine D |

|---|---|---|---|---|

| Winding Speed (RPM) | 400 | 350 | 450 | 300 |

| Coil Diameter Range (mm) | 20 - 100 | 30 - 120 | 15 - 90 | 25 - 150 |

| Max Wire Gauge (AWG) | 18 | 20 | 16 | 22 |

| Control Type | PLC | Microcontroller | PLC | PC Interface |

| Automatic Cut-off | Yes | No | Yes | Yes |

| Price Range ($) | 5000 - 7000 | 3000 - 5000 | 7000 - 9000 | 2500 - 4000 |

Assessing Your Business Scale and Production Requirements for Optimal Machine Choice

When selecting the best automatic coil winding machine for your business, a thorough assessment of your business scale and production requirements is crucial. Start by evaluating the volume of coils you plan to produce. Smaller operations may benefit from compact machines that are more affordable and require less floor space, whereas larger businesses focused on high-volume production might need state-of-the-art machinery capable of running continuously with higher precision and speed.

In addition to production volume, consider the specific types of coils your business requires. Different applications demand distinct winding techniques, wire sizes, and coil configurations. A machine that can easily adapt to various production needs will offer you greater flexibility. It's also important to think about your long-term growth; investing in a machine that can scale with your business will save you costs associated with replacing or upgrading equipment in the future.

Budgeting and Cost Considerations for Purchasing an Automatic Coil Winding Machine

When considering the purchase of an automatic coil winding machine, budgeting and cost considerations play a crucial role in making the right choice for your business. First, it's essential to establish a clear budget that reflects the specific requirements of your production needs and the features you desire in a machine. Understanding the total cost of ownership is vital, including not only the initial purchase price but also ongoing expenses such as maintenance, operation, and potential upgrades.

Additionally, it’s important to evaluate the variety of options available in the market ranging from entry-level machines to high-end models. While cheaper models may offer immediate savings, they might lack the durability and efficiency required for larger-scale operations. Investing in a machine that aligns with your volume and quality expectations can ultimately prove more cost-effective. Furthermore, consider exploring financing options or leasing agreements that can ease the upfront financial burden while still allowing your business to scale efficiently.

Automatic Coil Winding Machine Cost Considerations

Related Posts

-

How to Choose the Best Motor Coil Winding Machine for Your Needs in 2025

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide

-

Top 5 Motor Stator Winding Machines for Efficient Coil Production

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

Revolutionizing Efficiency How Motor Winding Automatic Machines Transform Manufacturing

-

What is Automated Machine Learning Its Impact on Industry Growth and Efficiency