How to Choose the Best Micro Coil Winding Machine for Your Needs

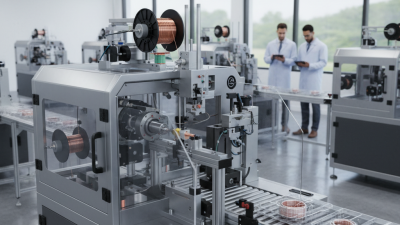

In the intricate world of coil manufacturing, the selection of the right equipment plays a pivotal role in ensuring quality and efficiency. As the demand for precision in applications such as electronics and medical devices increases, the importance of choosing the best micro coil winding machine has become paramount. According to Dr. Emily Carter, a leading expert in coil technology, “The right micro coil winding machine is not just a tool; it’s a cornerstone for any thriving manufacturing process.”

When navigating the myriad of options available on the market, potential buyers must consider various factors including winding speed, precision, and the types of coils being produced. Understanding these elements is essential to identify the machine that meets specific production requirements. Dr. Carter emphasizes that “investing time in research and understanding the unique needs of your operation can lead to significant improvements in productivity and product quality.”

Ultimately, the right micro coil winding machine can transform production capabilities, offering both reliability and advanced technological features. This guide aims to provide insights and criteria that will empower manufacturers to make informed decisions tailored to their unique operational needs.

Understanding Micro Coil Winding Machines and Their Applications

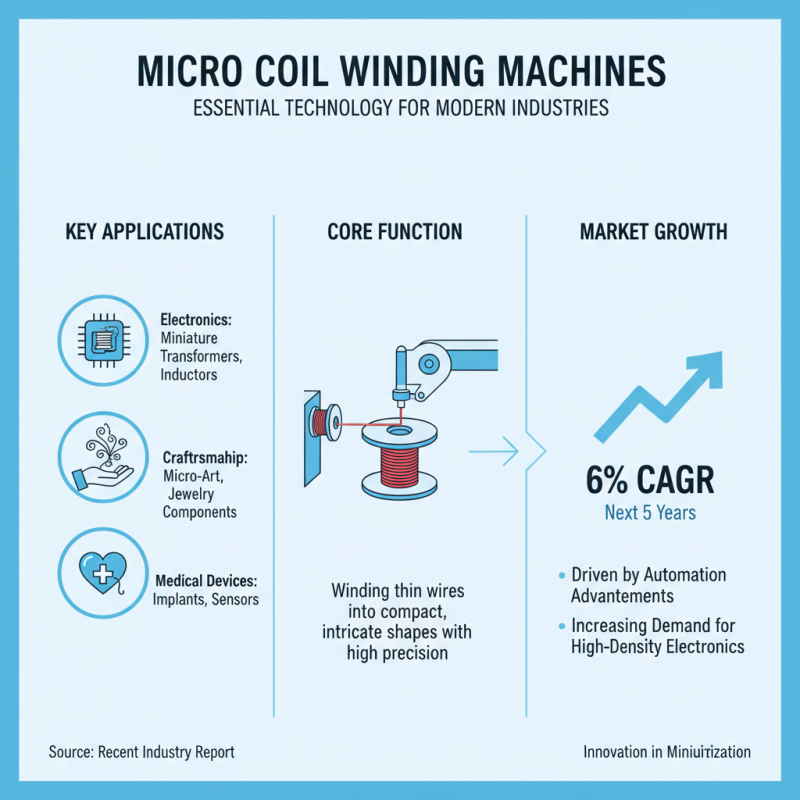

Micro coil winding machines have become essential tools in various industries, enabling the precise production of miniature coils for applications such as electronics, craftsmanship, and medical device manufacturing. These machines specialize in winding thin wire into compact, intricate shapes, which are crucial for components like miniature transformers, inductors, and magnetic coils. According to a recent industry report, the market for micro coil winding technology is expected to grow at a CAGR of 6% over the next five years, driven by advancements in automation and the increasing demand for high-density electronic components.

Understanding the applications of micro coil winding machines is vital for selecting the right model for your needs. These machines are widely used in sectors including telecommunications, automotive, and renewable energy, where precision and miniaturization are critical. In telecommunications, for instance, the demand for smaller and more efficient coils has prompted manufacturers to seek sophisticated winding solutions. Reports indicate that approximately 80% of electronic devices now require components that utilize micro coil technology, emphasizing the importance of selecting a machine that aligns with specific production requirements and quality standards.

When choosing a micro coil winding machine, it is essential to consider factors such as winding speed, tension control, and the variety of wire materials that can be processed. Machines that integrate advanced features, such as programmable control systems and real-time monitoring, offer greater flexibility and accuracy, making them suitable for diverse applications. The evolving landscape of manufacturing technology indicates that investing in a high-quality micro coil winding machine can significantly enhance production efficiency and product reliability.

Key Features to Consider When Selecting a Micro Coil Winding Machine

When selecting a micro coil winding machine, it is essential to consider several key features that will impact both efficiency and the quality of the final product. One of the primary factors is precision. Machines that offer a high degree of positional accuracy can greatly reduce errors and improve yield rates. According to industry reports, precision winding can lead to a decrease in scrap rates by up to 20%, highlighting the importance of selecting a machine that meets stringent accuracy requirements.

Another crucial aspect is the machine's compatibility with various wire sizes and materials. Flexibility in handling different wire gauges allows for a broader application range, which is essential in industries such as electronics and automotive. Data indicates that manufacturers utilizing micro coil winding machines capable of accommodating diverse materials see an increase in productivity by as much as 30%, as they can quickly shift between different tasks without extensive downtime.

Lastly, automation features should not be overlooked. Machines with advanced automation capabilities can significantly reduce labor costs and improve operational efficiency. Reports show that fully automated winding processes can save up to 40% in labor hours while increasing overall throughput. Investing in a micro coil winding machine with these key functionalities ensures that businesses can remain competitive in a rapidly evolving market.

Micro Coil Winding Machine Comparison

This chart represents a comparison of key features to consider when selecting a micro coil winding machine. Each feature is rated on a scale of 1 to 10, indicating its importance and performance in the context of micro coil winding requirements.

Evaluating Different Types of Micro Coil Winding Machines Available

When evaluating different types of micro coil winding machines, it's essential to consider the specific requirements of your projects.

There are several designs available, each tailored to unique applications ranging from electronics to medical devices.

Key aspects to weigh include the machine's precision, production speed, and ease of use.

Some machines are equipped with advanced features such as programmable controls, allowing for greater flexibility in coil designs and consistent outcomes.

Tips: When choosing a micro coil winding machine, assess your production volume.

If you plan to produce large quantities, look for machines with higher speed and efficiency ratings.

Alternatively, for smaller batch productions, a more versatile unit might be a better fit, offering various winding options without compromising quality.

Additionally, consider the support and training provided by the manufacturer. Reliable customer service can be invaluable, especially when troubleshooting.

Machines that allow for easy calibration and maintenance can save you time and resources in the long run.

Always review user feedback and test suitable machines if possible to ensure they meet your needs before making a final decision.

Assessing Your Production Needs and Volume Requirements

When selecting a micro coil winding machine, understanding your production needs and volume requirements is essential to ensure optimal performance and efficiency. According to industry reports, such as those published by Research and Markets, the global demand for coil winding machines is projected to grow at a compound annual growth rate (CAGR) of around 4.2% over the next five years. This growth emphasizes the importance of assessing your specific production volume, whether you're operating on a small scale or planning for large-scale manufacturing. Identifying the quantity of coils needed per day, week, or month can help narrow down which features are crucial for your machine, such as speed, precision, and automation capabilities.

Additionally, it is vital to consider the technical specifications that align with your production requirements. For instance, if your operation necessitates high flexibility for various coil designs, investing in a machine that accommodates multiple coil sizes and configurations can significantly enhance productivity. Furthermore, a study conducted by the International Journal of Advanced Manufacturing Technology indicates that businesses optimizing their coil production line can see efficiency gains of up to 30% with the right machinery. Therefore, aligning your machine choice with your operational needs will not only improve manufacturing throughput but also reduce downtime and improve overall production quality.

How to Choose the Best Micro Coil Winding Machine for Your Needs

| Machine Type | Production Capacity (Coils/Hour) | Wire Diameter Range (mm) | Voltage Requirement (V) | Price Range (USD) | Best Applications |

|---|---|---|---|---|---|

| Automatic Micro Coil Winder | 2000 | 0.02 - 0.5 | 220 | $5,000 - $10,000 | Electric Motors, Transformers |

| Semi-Automatic Coil Winder | 1500 | 0.03 - 0.7 | 110 | $3,000 - $6,000 | Inductors, Sensors |

| Manual Micro Coil Winding Machine | 500 | 0.05 - 1.0 | 220 | $1,000 - $2,500 | Small Scale Projects, DIY |

| High Precision Coil Winder | 1800 | 0.02 - 0.4 | 220 | $7,500 - $12,000 | Medical Devices, Aerospace |

Budget Considerations for Purchasing a Micro Coil Winding Machine

When considering the purchase of a micro coil winding machine, budget is a crucial factor that can significantly influence your decision. Establishing a clear budget involves not only assessing the initial purchase cost but also taking into account long-term operational expenses. Basic models may appear cost-effective initially, but if they lack durability or advanced features, they could lead to increased costs for repairs and maintenance over time. Therefore, it’s essential to evaluate the overall value, balancing the upfront investment with projected longevity and performance.

Additionally, it's important to understand the varying price ranges in the market. Setting a budget that aligns with your specific needs will help narrow down your options. For those who intend to use the machine for larger production runs, it may be worthwhile to allocate more funds for a high-quality model that offers precision and efficiency. Conversely, if your projects are limited in scale, a budget-friendly model may suffice. Being transparent about your financial constraints enables you to explore models that fit your criteria without overspending or compromising quality.

Related Posts

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

2025 Top 5 Used Coil Winding Machines You Need for Your Business

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide

-

How to Choose the Best Programmable Coil Winding Machine for Your Needs

-

What is a Coiling Machine and How Does it Work for Your Projects

-

How to Choose the Best Automatic Coil Winding Machine for Your Business Needs