How to Choose the Best Programmable Coil Winding Machine for Your Needs

When it comes to choosing the right equipment for wire and coil manufacturing, the programmable coil winding machine stands out as an essential tool for enhancing production efficiency and precision. These machines are designed to automate the winding process, allowing for much greater control over winding parameters such as tension, speed, and coil configuration. For businesses looking to invest in this technology, understanding the various features and specifications of programmable coil winding machines is crucial to ensure they meet specific production needs.

Selecting the best programmable coil winding machine involves a careful assessment of several key factors. First and foremost, users should consider the type of coils they plan to produce, as well as the materials involved. Additionally, the production volume and the level of automation required can significantly influence the choice of machine. This introduction aims to guide manufacturers through the process of evaluating their unique requirements and the features that different machines offer. By carefully analyzing these elements, businesses can make informed decisions that lead to enhanced operational efficiency and better product quality.

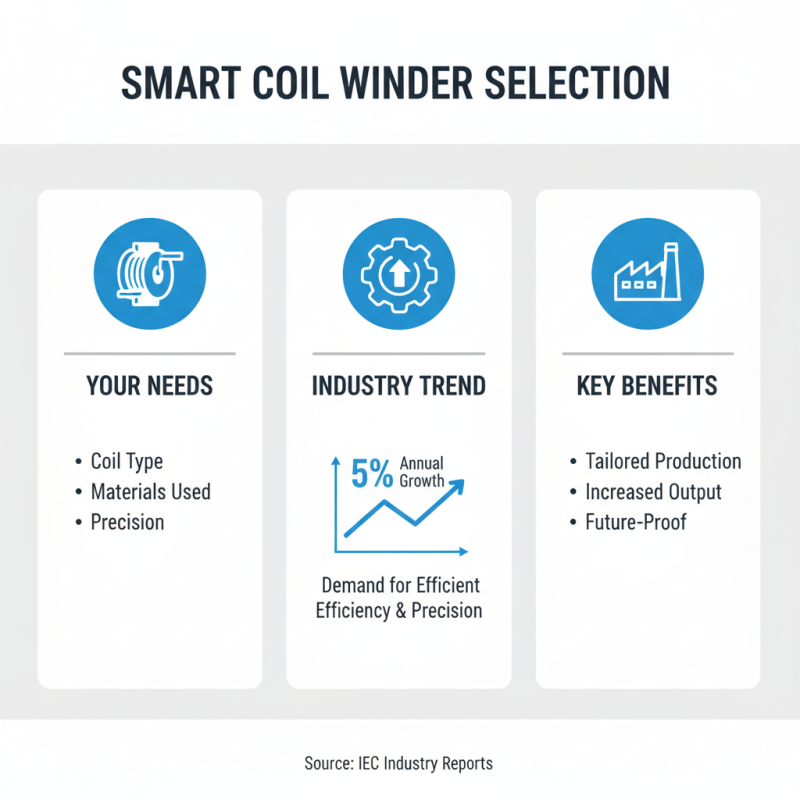

Understanding Your Coil Winding Requirements: A Comprehensive Analysis

When selecting a programmable coil winding machine, it is essential to thoroughly understand your specific coil winding requirements. This involves an analysis of several key factors, including the type of coils you intend to produce, the materials you will use, and the precision needed for your applications. According to industry reports from organizations such as the International Electrotechnical Commission, the demand for efficient and precise coil winding solutions has been on the rise, with projections indicating a 5% annual growth rate in the sector. This upswing underscores the need to tailor your machine choice to meet the evolving requirements of your projects.

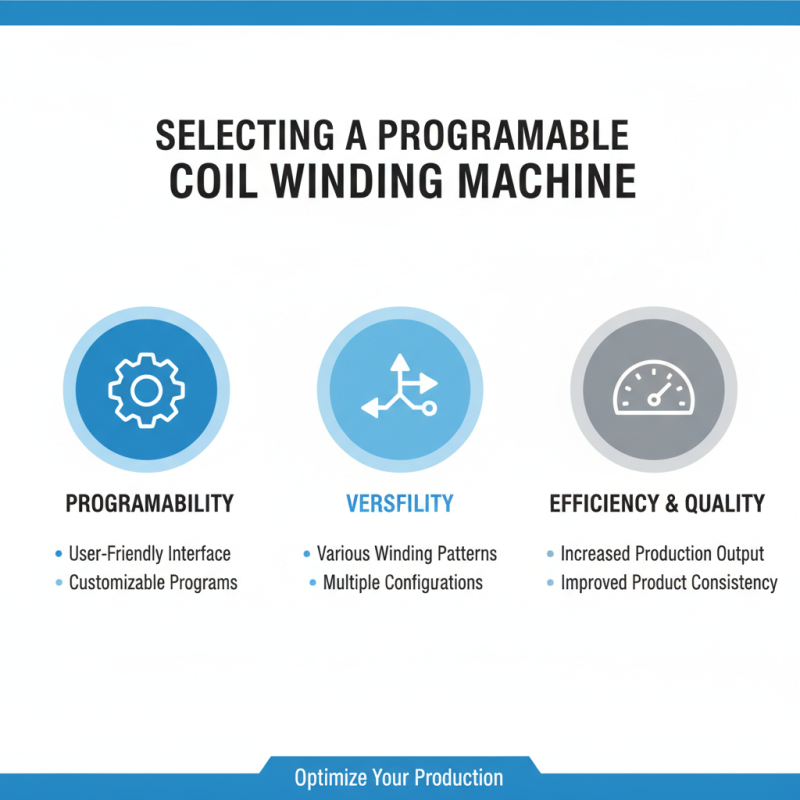

Tips for choosing the right machine include considering the machine's winding speed and torque capabilities, which directly affect productivity and the quality of the coils produced. Additionally, pay attention to the control and programming features, as advanced machines allow for more complex winding patterns and configurations, enhancing versatility. For instance, machines equipped with user-friendly interfaces and software that facilitate seamless design modifications are now more accessible and crucial for maintaining competitive advantages.

Another aspect to consider is the size and weight of the coils, which can impact the type of machine suitable for your operation. Lightweight materials may require different handling and winding techniques compared to traditional heavier materials. Investing in a machine that offers adjustable tension settings and compatible tooling can further optimize your coil production process, ensuring efficiency and consistency across various project demands.

Key Features to Evaluate in Programmable Coil Winding Machines

When selecting a programmable coil winding machine, it is essential to evaluate several key features that can significantly impact your production efficiency and output quality. One of the primary factors to consider is the machine's programmability. Look for machines that offer user-friendly interfaces and customizable programs, enabling operators to easily adjust winding specifications according to different project requirements. A versatile machine that supports various winding patterns and configurations can enhance flexibility and streamline the production process.

Another critical feature to assess is the precision and accuracy of the coil winding machine. High-quality machines should provide consistent winding tension and alignment, which are vital for producing coils that meet stringent quality standards. Additionally, consider machines equipped with advanced sensors and controls that monitor winding parameters in real-time, allowing for immediate adjustments to maintain optimal performance. Finally, pay attention to the machine's build quality and durability, as these factors contribute to long-term reliability and reduced maintenance costs, ensuring that your investment serves your needs effectively over time.

Analyzing the Cost-Effectiveness of Different Coil Winding Solutions

When selecting a programmable coil winding machine, one of the most critical factors to consider is cost-effectiveness. A recent industry report indicates that efficient coil winding solutions can reduce production costs by up to 20%. This reduction is primarily achieved through the optimization of material usage and labor efficiency. Machines equipped with programmable features allow for rapid changeovers between different projects, minimizing downtime and ensuring that operators can switch tasks with greater ease. This operational flexibility can lead to significant savings over time, especially for businesses that deal with varied product lines.

Additionally, the total cost of ownership (TCO) is an important aspect when evaluating different winding machines. Studies have shown that while initial purchase costs may vary, the long-term expenses associated with maintenance, operational efficiency, and energy consumption can dramatically affect the overall budget. Advanced programmable machines, often designed with energy-efficient components, can reduce energy consumption by as much as 30%, reflecting the growing demand for sustainable manufacturing practices. Investing in a higher-quality machine may yield superior cost-effectiveness when factoring in longevity and lower operational costs, thereby presenting a more favorable financial scenario in the long run.

Importance of Machine Specifications for Optimal Performance and Efficiency

When selecting a programmable coil winding machine, understanding machine specifications is crucial to achieving optimal performance and efficiency. The specifications, including winding speed, torque, and control systems, directly influence the quality of the coils produced and the machine's reliability during operation. For instance, a higher winding speed can increase productivity, but it is essential to ensure that the motor and drive system can handle the stress. Additionally, having a control system that allows for precise adjustments can help maintain the consistency and accuracy of the winding process.

Tips for evaluating machine specifications include analyzing the coil requirements for your specific projects. Consider the wire gauge and insulation type, as these factors can impact the windings’ performance and durability. Checking for features like programmable settings and user-friendly interfaces will also enhance operational efficiency. Furthermore, assess the machine's capability to adapt to future needs, allowing for easier upgrades as technology advances or production demands change.

Another critical aspect is the machine's safety features and maintenance requirements. A machine equipped with automatic shut-off and overload protection can prevent accidents and product damage. Regular maintenance schedules and easily accessible service options should also be clarified before purchasing. These considerations not only ensure a better investment but also contribute to long-term operational effectiveness.

How to Choose the Best Programmable Coil Winding Machine for Your Needs - Importance of Machine Specifications for Optimal Performance and Efficiency

| Specification | Description | Importance |

|---|---|---|

| Coil Size | Max and min coil diameter and width. | Ensures compatibility with your production requirements. |

| Winding Speed | Speed at which the machine winds the coil. | Affects production rates and efficiency. |

| Control Type | Manual or programmable control options. | Influences ease of use and customization options. |

| Power Supply | Voltage and phase of the power required. | Essential for ensuring machine operates smoothly. |

| Precision | Accuracy in winding and coil formation. | Critical for meeting product specifications. |

| Automation Level | Extent to which the winding process is automated. | Reduces labor costs and improves efficiency. |

| Safety Features | Incorporation of safety mechanisms and alerts. | Protects operators and prevents accidents. |

| Maintenance Requirements | Frequency and ease of maintenance tasks. | Critical for long-term operation and cost-effectiveness. |

Comparing Leading Brands and Models in the Coil Winding Industry

When navigating the world of coil winding machines, it’s crucial to compare the leading brands and models to identify the one that best fits your specific requirements. Each manufacturer tends to offer unique features, such as varying degrees of automation, speed settings, and control interfaces. Some models might excel in precision winding, making them ideal for specialized applications, while others may prioritize high production rates to meet bulk manufacturing demands. Understanding these differences will help you tailor your choice to your operational needs.

Another important aspect to consider is the available support and training offered by different brands. Since coil winding machines can be complex, having access to a robust customer service system and technical support can greatly influence your experience. Some manufacturers also provide comprehensive training programs for operators, ensuring that you get the most out of your investment. By weighing these factors against each other, you can make a more informed decision that aligns with both your immediate and long-term production goals.

Comparison of Programmable Coil Winding Machines

Related Posts

-

How to Choose the Best Motor Coil Winding Machine for Your Needs in 2025

-

Top 5 Motor Stator Winding Machines for Efficient Coil Production

-

What is an Auto Winding Machine? Exploring Efficiency and Precision in Coil Production

-

What is Automated Machine Learning Its Impact on Industry Growth and Efficiency

-

2025 Top Spindle Winding Machine Innovations and Buying Guide

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide