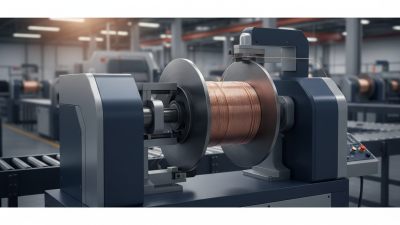

2026 Best Motor Winder Machine for Efficient Operations?

The importance of choosing the right motor winder machine has never been clearer. Recent industry analyses reveal that companies utilizing advanced winding technology experience up to 30% increased efficiency. As noted by industry expert Dr. Emily Chen, "Investing in the best motor winder machine today leads to greater long-term savings and efficiency."

Manufacturers face pressure to optimize operations amid rising costs. Motor winder machines play a pivotal role in electrical equipment production. Companies should evaluate their options carefully, as one mistake can lead to significant setbacks. In fact, nearly 40% of businesses have encountered problems due to outdated winding technology.

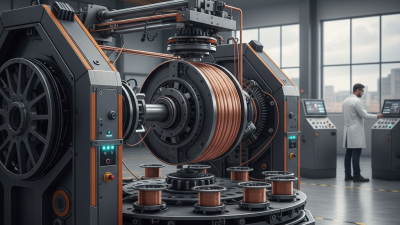

While many machines boast high performance, the reality can differ. Not all manufacturers provide transparent data on performance metrics. Understanding the capabilities of a motor winder machine requires in-depth research and discernment. The quest for the best machine may reveal flaws in current practices, prompting manufacturers to refine their operations and rethink their investments.

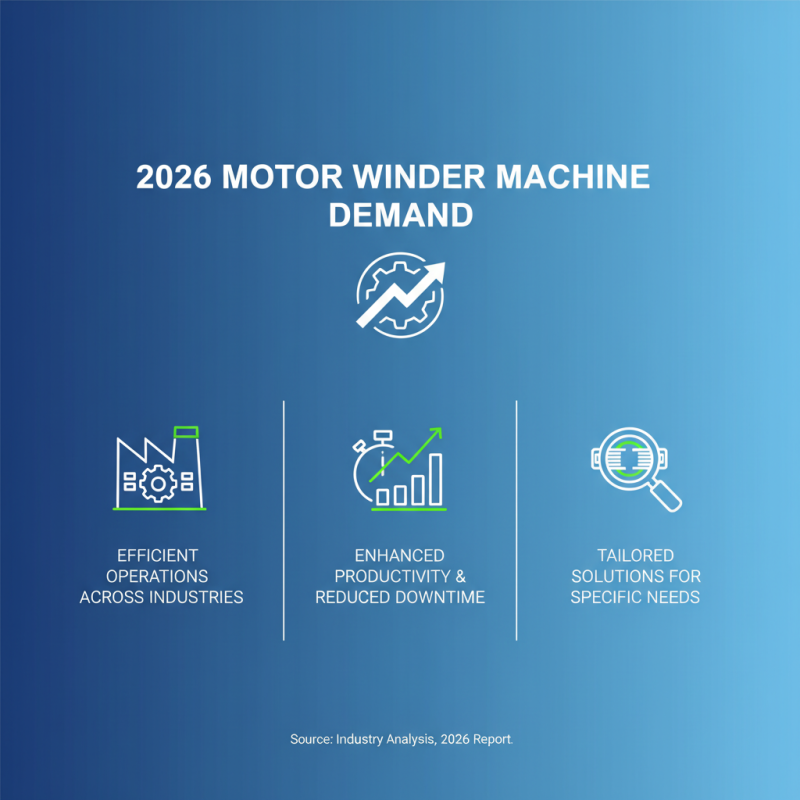

Overview of Motor Winder Machines in 2026

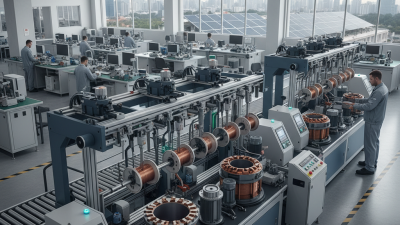

In 2026, motor winder machines are witnessing significant advancements. The industry is expected to grow at a CAGR of 5.2%, reaching $1.7 billion by 2028. This growth indicates a surge in demand for efficient operations across various sectors, including automotive and industrial manufacturing. Key features now include: automated winding capabilities, real-time monitoring, and energy efficiency.

A recent study highlights that companies utilizing advanced winding machines can improve productivity by up to 30%. This improvement stems from reduced cycle times and increased precision. Yet, not all manufacturers have adapted. Many still rely on outdated equipment. This hesitation can lead to operational inefficiencies.

Moreover, the market is facing challenges. The integration of smart technology requires substantial investment. Additionally, training personnel to operate these new systems can be time-consuming. Companies may struggle with the transition. Inevitably, some will lag behind. These reflections signal the need for careful planning and investment in training to avoid missing out on potential benefits.

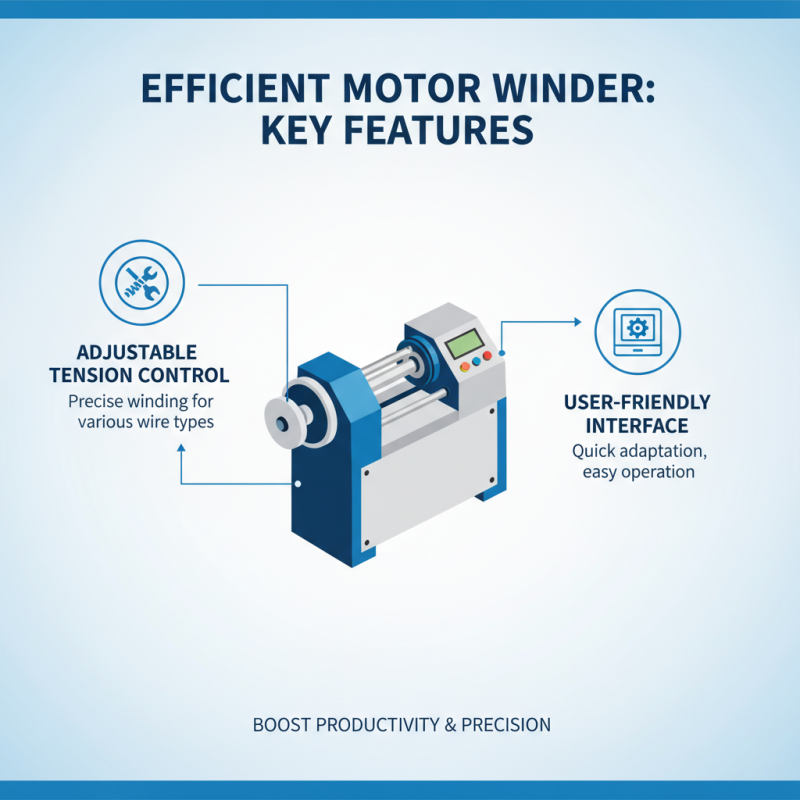

Key Features to Look for in Efficient Motor Winder Machines

When searching for an efficient motor winder machine, consider essential features that enhance productivity. Look for machines with adjustable tension control. This allows precise winding of various wire types. A user-friendly interface is also critical. It helps operators quickly adapt to different winding tasks.

Another key feature is speed regulation. Machines that offer variable speeds cater to diverse winding requirements. Additionally, robust build quality is important. While lightweight machines may be easy to handle, they often lack durability. A balance between portability and strength is necessary.

Don’t overlook the importance of automated functions. Machines that automate winding reduce manual errors. However, they may require a learning curve. Regular maintenance is crucial too. Neglect can lead to operational inefficiencies. Take time to understand each feature. This is vital for long-term performance.

Top Brands and Models of Motor Winder Machines in 2026

In 2026, the demand for motor winder machines continues to grow. Various industries rely on these machines for efficient operations. Many factories seek systems that enhance productivity and reduce downtime. The key is finding the right model tailored to specific needs.

Recent industry reports indicate that advanced motor winder machines have improved efficiency by up to 30%. This significant leap is attributed to enhanced technology and better design. For instance, some models use real-time monitoring systems to track performance. Users appreciate these features, yet many express concerns over maintenance costs. Although machines are efficient, regular upkeep is crucial. If neglected, performance might drop.

Popular choices in 2026 include models with user-friendly interfaces and low energy consumption. Some systems focus on sustainability, reducing their carbon footprint. Yet, challenges remain. Adapting to changing regulations and standards creates uncertainty. While many brands excel, not all meet the high standards expected by clients. It's vital for businesses to weigh options carefully. Balancing cost and quality can prove difficult.

Comparative Analysis of Motor Winder Machines Performance

When evaluating motor winder machines, performance is key. These machines come in various designs and operational capabilities. Some models excel in speed, while others focus on precision. It's crucial to analyze how these differences impact overall efficiency. A machine that winds quickly may struggle with maintaining tight tolerances, which can lead to inefficiencies in production.

One significant factor is the machine's adaptability to different wire types. Machines that handle a variety of materials tend to offer more versatility. However, this adaptability often comes with trade-offs in speed or ease of use. Some operators may find complex settings overwhelming. User experience is essential in determining whether a machine is effective or a hindrance. Misalignment in expectations can lead to frustration.

Another aspect is maintenance requirements. Machines that require frequent calibrations can disrupt operations. Simple machines may have fewer issues but might lack advanced features. Operators need to balance between efficiency and operational simplicity. In some cases, it may be necessary to rethink the criteria for selecting a motor winder. Real performance analysis helps identify which characteristics benefit your specific needs, guiding better decision-making.

2026 Best Motor Winder Machine Performance Comparison

Best Practices for Operating Motor Winder Machines Efficiently

Efficient operation of motor winder machines requires attention to detail. Regular maintenance is crucial. Check the machine's calibration regularly. A poorly calibrated machine can lead to inaccurate winding. This increases the risk of errors during production.

Training operators is essential. New users often make mistakes that experienced workers avoid. Offer hands-on practice sessions. Encourage questions and discussions among staff. This fosters a collaborative environment. Operators must understand the machine's capabilities and limitations. They should know how to troubleshoot basic issues.

Additionally, monitor production schedules closely. Overloading machines can cause wear and tear. Operators may push limits to meet deadlines, leading to breakdowns. Implement a system to track machine performance. Analyze data to identify patterns that indicate problems. Reflection and adjustment are needed often. This ensures consistent efficiency and minimizes downtime.

2026 Best Motor Winder Machine for Efficient Operations

| Machine Model | Power Consumption (kW) | Max Winding Speed (RPM) | Weight (kg) | Features |

|---|---|---|---|---|

| Model A | 2.5 | 3000 | 150 | Automatic tension control |

| Model B | 3.0 | 3500 | 180 | User-friendly interface |

| Model C | 1.8 | 2800 | 120 | Quick changeover system |

| Model D | 2.2 | 3200 | 160 | Integrated energy-saving features |

| Model E | 2.0 | 2900 | 140 | Advanced monitoring system |

Related Posts

-

Essential Tips for Choosing the Right Motor Winding Machine for Your Needs

-

What is the Best Automatic Winding Machine in 2026?

-

2026 Best Heavy Duty Coil Winding Machine for Your Industrial Needs?

-

Top 10 Benefits of Using an Automatic Wire Coiling Machine for Your Business

-

Top 10 Automatic Wire Coiling Machines for Efficient Production

-

What is a Coiling Machine and How Does it Work for Your Projects