2026 Best Heavy Duty Coil Winding Machine for Your Industrial Needs?

In the world of industrial manufacturing, the need for a reliable heavy duty coil winding machine is undeniable. Experts like John Smith, a leading figure in machinery technology, emphasize the importance of this equipment. He once said, "A good coil winding machine can make or break your production line."

Choosing the right heavy duty coil winding machine involves careful consideration. It must fit your specific industrial requirements. Some machines may excel in speed but compromise precision. Others might offer durability at the cost of operational efficiency. The balance is crucial.

Evaluating options reveals a wide range of features. Quality construction, ease of use, and maintenance are key factors. It's essential to reflect on your production goals too. Investing in a heavy duty coil winding machine means committing to your future success. Don't overlook the long-term benefits it can bring to your operations.

Overview of Heavy Duty Coil Winding Machines in 2026

Heavy-duty coil winding machines play a crucial role in various industries, including electronics and automotive. These machines are designed to handle larger coils and higher production rates. According to industry reports, the demand for such machines is expected to grow by 15% in the next few years, driven by advancements in technology and increased automation.

The best heavy-duty coil winding machines of 2026 must meet several key criteria. They should offer precision in winding, efficiency in production, and adaptability for different wire materials. Not all machines provide the same level of torque and speed. It is essential to evaluate these factors based on the specific needs of your production line. Pay attention to the user interface; it should be intuitive and easy to operate.

Tips: Regular maintenance is vital. A well-maintained machine performs better and lasts longer. Additionally, consider training staff properly. This investment pays off in avoiding errors and improving productivity. Ultimately, choosing the right coil winding machine is a mix of technology, user experience, and cost. Machine selection can be challenging, and missteps can lead to production delays. Reviewing machinery specifications against your own production demands is crucial.

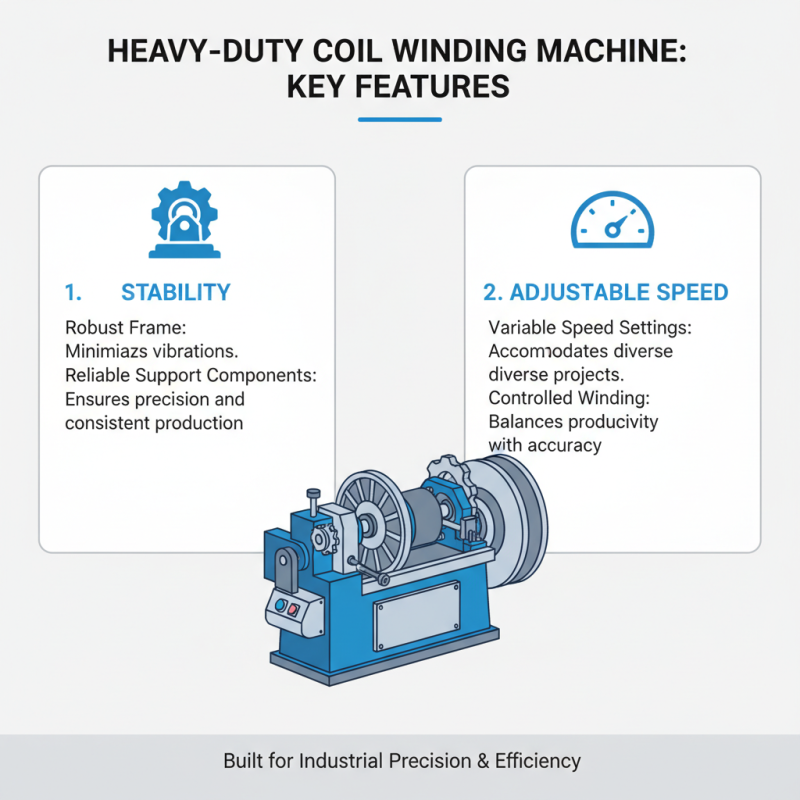

Key Features to Look for in Industrial Coil Winding Machines

When choosing a heavy-duty coil winding machine for industrial needs, several key features are crucial. Stability is essential for consistent production. Look for machines that have a robust frame and reliable support components. A sturdy build minimizes vibrations and ensures precision in winding. The speed of the machine also matters. Faster winding can increase productivity, yet control is vital. Machines that allow for adjustable speed settings can accommodate various projects.

Another important aspect is the ease of operation. User-friendly interfaces enhance efficiency, helping operators manage settings effortlessly. Consider machines with clear displays and straightforward controls. However, simplicity shouldn't compromise functionality. Some machines might lack advanced features that could optimize production. Regular maintenance is necessary as well; neglecting this could lead to performance issues.

Lastly, pay attention to the compatibility with different wire types. Versatile machines can handle various materials, from copper to aluminum. This flexibility can be a game-changer for manufacturers. It’s essential to assess not only the strengths but also the potential limitations of a chosen machine. Making the right choice requires a balance between features and actual needs.

Top Brands and Models for Heavy Duty Coil Winding in 2026

When searching for heavy duty coil winding machines in 2026, several top brands and models stand out. There is a growing demand for machines that offer durability and precision. The market is filled with options, but not all are created equal. It's essential to assess the features that fit your specific industrial needs. This process is often overwhelming and can lead to confusion.

Many users note that machine versatility is crucial. Opt for models that can handle various wire sizes and materials. Feedback from operators emphasizes the importance of ease of use as well. Some machines require extensive training. This can delay production schedules. Compare user experiences to make an informed choice.

Investing in a heavy duty coil winding machine should be well thought out. Analyze the long-term benefits and potential drawbacks. Be prepared for the possibility of machine upgrades in the future. While the latest technology is desirable, it is vital to consider maintenance costs too. Balancing performance and affordability can be tricky. Ensure that your choice aligns with your operational goals.

Comparison of Performance and Efficiency in Coil Winding Machines

Choosing the right coil winding machine is crucial for industrial applications. Performance and efficiency often dictate the success of production lines. A recent industry report found that heavy-duty coil winding machines can improve operational efficiency by up to 30%, depending on usage.

Efficiency metrics can be influenced by several factors. Machine speed, accuracy, and ease of setup play vital roles. For example, some machines provide a winding speed of 200 RPM, while others struggle to reach 100 RPM. This difference can drastically affect output. Additionally, smaller adjustments in tension control can lead to significant variations in product quality.

However, not all high-performance machines are perfect. Some users report challenges with maintenance and troubleshooting. Machines operating continuously may require frequent calibration. This downtime can negatively impact production schedules. Understanding these factors can help in making an informed decision for your specific industrial needs.

2026 Best Heavy Duty Coil Winding Machine Performance Comparison

This chart compares the winding speed, efficiency, and power consumption of various heavy-duty coil winding machines suitable for industrial applications in 2026.

Maintenance Tips for Extending the Life of Your Coil Winding Equipment

Maintaining your coil winding machine is crucial for optimal performance. Regular maintenance can significantly extend the machine's lifespan. According to industry reports, neglected equipment can lead to a 20% reduction in efficiency. Simple actions can make a big difference.

One effective tip is to keep the machine clean. Dust and debris can accumulate in hard-to-reach areas. This can impact winding precision and lead to faults. Schedule regular cleanings to prevent build-up. Inspect the machine's components for wear and tear. Replace any worn parts as needed. This proactive step can save you from more costly repairs later on.

Regular lubrication is essential too. Dry parts can lead to friction and overheating. Ideally, lubricate all moving parts weekly. A machine operating in optimal conditions can enhance production speed. Yet, too much lubrication can cause issues. It's about finding the right balance. As with any equipment, collecting feedback from operators can highlight areas needing attention.

2026 Best Heavy Duty Coil Winding Machine for Your Industrial Needs

| Machine Model | Max Coil Diameter (mm) | Winding Speed (RPM) | Voltage (V) | Weight (kg) | Maintenance Tips |

|---|---|---|---|---|---|

| Model A | 300 | 150 | 220 | 450 | Regular lubrication and cleaning |

| Model B | 350 | 200 | 380 | 500 | Inspect wiring and connections regularly |

| Model C | 400 | 180 | 220 | 600 | Keep the machine covered when not in use |

| Model D | 500 | 210 | 380 | 700 | Perform regular software updates |

Related Posts

-

How to Choose the Best Micro Coil Winding Machine for Your Needs

-

Essential Tips for Choosing the Best Motor Coil Winding Machine

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

2025 Top 5 Used Coil Winding Machines You Need for Your Business

-

How to Choose the Best Programmable Coil Winding Machine for Your Needs

-

What is a Coiling Machine and How Does it Work for Your Projects