What is the Best Automatic Winding Machine in 2026?

In 2026, the automatic winding machine market will see significant advancements. These machines are essential for industries like textiles and electronics. They help streamline production processes. As technology evolves, so do the features of these machines.

Choosing the best automatic winding machine can be challenging. There are many brands and models available. Each offers unique specifications and benefits. Some machines excel in speed, while others focus on precision. It is vital to consider what your specific needs are.

Buyers often overlook the importance of service and support. A reliable machine with poor customer service might lead to frustration. Additionally, cost should not be the only factor. Balancing quality and price is crucial. Reflecting on these details will aid in making the right choice.

Overview of Automatic Winding Machines in 2026

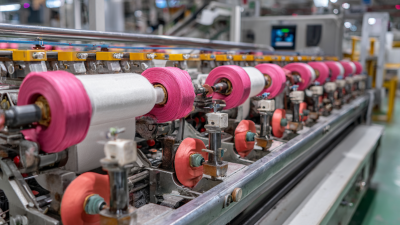

Automatic winding machines have evolved significantly in 2026. These tools are essential for various industries, especially in manufacturing and electronics. They automate the process of winding wire, saving time and enhancing precision. Modern designs have improved efficiency and reduced waste. Yet, many machines still struggle with inconsistent tension and alignment issues.

When selecting an automatic winding machine, consider specific features. A reliable machine should have adjustable speed settings and easy setup options. A durable design withstands long production hours. Maintenance is crucial. Regularly inspect and clean the machine to prevent errors. Preventative care helps improve longevity.

Tip: Always read user reviews before purchasing. They provide insights into real-life performance. Explore the machine's warranty and support options carefully. This can save headaches later on. Remember, the best machine for your needs might not be the most expensive one.

Key Features to Consider When Choosing an Automatic Winding Machine

When selecting an automatic winding machine, consider several key features to ensure you make the right choice. Speed is essential. A machine that operates quickly can save time in production. However, a balance is needed. High speed should not compromise winding quality.

Precision matters too. A machine that provides accurate winding reduces waste. This reliability is crucial for long-term operations. Automatic tension control is another feature to look for. It ensures consistent results, especially for delicate materials. Without this control, issues like slippage can occur.

Tips: Always check user reviews. They can provide insights into performance. Don't skip demos. Watching a machine in action helps to assess its effectiveness. Additionally, consider maintenance requirements. A complicated machine may lead to more downtime and frustration. Make sure you have the resources for upkeep.

What is the Best Automatic Winding Machine in 2026? - Key Features to Consider When Choosing an Automatic Winding Machine

| Model | Winding Speed (RPM) | Max Coil Diameter (mm) | Power Consumption (W) | User Interface | Price (USD) |

|---|---|---|---|---|---|

| Model A | 1200 | 150 | 300 | Touchscreen | 2000 |

| Model B | 1500 | 200 | 250 | LCD Display | 2500 |

| Model C | 1000 | 100 | 280 | Physical Buttons | 1800 |

| Model D | 1400 | 180 | 320 | Smart Control | 3000 |

Top Brands and Models of Automatic Winding Machines in 2026

When choosing an automatic winding machine in 2026, several models stand out. Key features often include precision winding capabilities and automation efficiency. These machines can enhance productivity significantly. They are suitable for various industries, including textiles and electronics.

Notable models offer user-friendly interfaces. Control screens are easy to navigate, which benefits operators. Additionally, some machines support multiple winding techniques. This versatility caters to unique production needs. However, potential buyers should consider the initial investment and maintenance costs.

Environmental factors also play a role in the decision-making process. Some machines are designed to minimize energy consumption. This aspect is increasingly important for businesses focusing on sustainability. Feedback from users suggests that while these machines are efficient, occasional calibration is necessary. Regular checks ensure optimal performance. These considerations are crucial for a wise purchase in 2026.

User Reviews and Ratings of Leading Winding Machines

When considering the best automatic winding machine in 2026, user reviews offer a wealth of insight. Many users praise machines that boast quick setup times and user-friendly interfaces. Some highlight features like programmable winding patterns. They appreciate how these machines help streamline processes, saving time and resources. However, not all reviews are glowing. A few users report issues with the machines jamming or making unexpected noises. This inconsistency can lead to frustration during long production runs.

Moreover, efficiency is often a central theme in user feedback. Machines that can handle different spool sizes receive high marks. Yet, there are complaints about difficulty in switching between sizes. Some users desire better instructional materials or more accessible support. Reviews frequently mention the importance of durability, but occasional breakdowns do occur, prompting reflections on long-term reliability. Not all models have stellar durability, a concern for many who invest in these machines. Finding a balance between price and quality is an ongoing challenge for many users in the market.

Future Trends and Innovations in Automatic Winding Technology

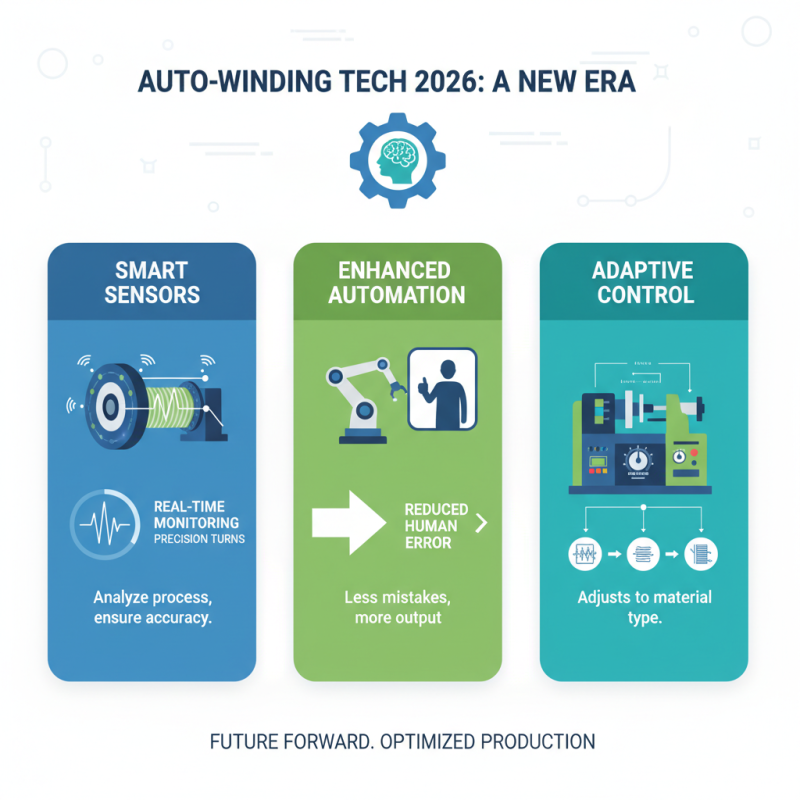

The landscape of automatic winding technology is undergoing significant transformation. In 2026, we may witness machines that incorporate smart sensors for real-time monitoring. These sensors will analyze the winding process, ensuring precision in each turn. Enhanced automation will help reduce human errors and improve overall efficiency. Imagine a machine that can adjust tension and speed based on the material used.

Future designs will likely prioritize sustainability. Energy-efficient systems will become commonplace, minimizing environmental impact. Moreover, the potential integration of renewable energy sources could redefine how these machines operate. However, designers face challenges in maintaining efficiency while meeting eco-friendly goals. The balance requires deep reflection and innovative thinking.

User interfaces will also evolve. Intuitive controls and interactive displays may simplify machine operation. Despite these advancements, there remains a question of accessibility. Not all industries will adapt equally to these new technologies. Some sectors may struggle, highlighting the need for ongoing support and training. As innovations continue, it’s essential to keep these disparities in mind.

Related Posts

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

2025 Top 5 Used Coil Winding Machines You Need for Your Business

-

What is a Coiling Machine and How Does it Work for Your Projects

-

How to Choose the Best Micro Coil Winding Machine for Your Needs

-

Top 2025 Coil Winding Machines Features Benefits and Buying Guide

-

Auto Winding Machine Tips for Efficient Operation and Maintenance Guide