Top 10 Benefits of Using an Automatic Wire Coiling Machine for Your Business

In today’s fast-paced industrial landscape, efficiency and precision are paramount for businesses seeking to maintain a competitive edge. One essential tool that can significantly enhance operational productivity is the automatic wire coiling machine. This innovative technology not only streamlines the winding process but also ensures a level of consistency and accuracy that manual methods simply cannot achieve. By automating the coiling process, businesses can save time, reduce labor costs, and minimize errors, ultimately leading to a more efficient production line.

Moreover, the adoption of an automatic wire coiling machine can lead to improved product quality. With its ability to create uniform coils, this machine eliminates variability that often arises from manual handling, resulting in products that meet stringent quality standards. As industries demand higher quality and faster turnaround times, leveraging such advanced machinery can be a decisive factor for success. In the following sections, we will explore the top ten benefits of integrating an automatic wire coiling machine into your business operations, highlighting how it can transform your workflow and drive profitability.

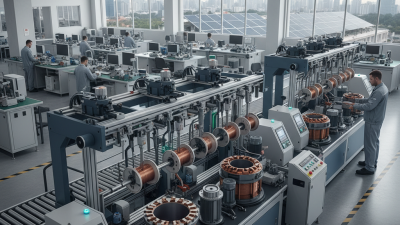

Benefits of Increased Efficiency in Production with Automatic Wire Coiling Machines

The adoption of automatic wire coiling machines has significantly transformed production efficiency across various industries. According to a report from the International Wire Association, manufacturing processes that implement automation can experience up to a 30% increase in output, driven by the reduction of manual labor hours and the minimization of human error. By employing automated systems, businesses streamline the wire coiling process, allowing for faster coil production times and a more consistent product quality. This not only accelerates the flow of goods to market but also enhances overall operational productivity.

Moreover, the operational benefits extend to improved resource allocation and cost savings. The annual report from the Manufacturing Institute highlights that companies utilizing automated machinery can reduce their labor costs by approximately 20%, while also decreasing material waste through precise coiling techniques. This efficiency opens up opportunities for businesses to reinvest in innovation or expand their offerings, ultimately leading to increased competitive advantage. As industries continue to embrace automation, the impact on production efficiency from automatic wire coiling machines is becoming increasingly evident, paving the way for smarter manufacturing solutions.

Improved Consistency and Quality in Wire Coiling Processes

An automatic wire coiling machine significantly enhances the consistency and quality of wire coiling processes, making it an invaluable asset for businesses in various industries. This equipment is designed to produce precisely coiled wire with uniform tension and spacing, eliminating the variations often seen in manual coiling. As a result, the finished products consistently meet high standards of quality, which is essential for customer satisfaction and regulatory compliance.

To maximize the benefits of using an automatic wire coiling machine, it is crucial to follow best practices. First, regularly calibrate the machine to ensure that it is operating at peak performance. Small adjustments can make a big difference in the consistency of the coils produced. Additionally, consider the type and quality of wire being used; selecting high-quality materials can contribute to a more uniform end product.

Furthermore, implementing routine maintenance checks will keep the machinery in optimal condition, preventing potential issues that could affect the quality of the wire coils. Keep the work area clean and organized to ensure that the coiling process runs smoothly without interruptions. By focusing on these tips, businesses can fully leverage the advantages of automatic wire coiling machines, leading to improved operational efficiency and product quality.

Reduction of Labor Costs through Automation in Wire Manufacturing

In the fast-paced world of wire manufacturing, the adoption of automatic wire coiling machines has proven to be a game-changer, particularly in reducing labor costs. A recent industry report indicates that automation can cut labor expenses by as much as 30% while simultaneously increasing production efficiency. This translates to significant savings for businesses, allowing funds to be redirected into other crucial areas such as research and development or marketing efforts.

Automation not only lowers labor costs but also minimizes the risks associated with manual handling, which can lead to workplace injuries and subsequent costs. A shift towards automated solutions aids in maintaining consistent product quality, as machines perform repetitive tasks with precision. A study found that companies utilizing automated machinery report a 50% decrease in defects, allowing businesses to enhance their reputation for quality among clients.

Tips for businesses considering automation include investing in training for existing staff to operate new machines effectively. Leveraging data analytics to track performance post-installation can also ensure that the investment yields the desired productivity gains. Additionally, collaborating with industry experts during the transition phase can guide businesses in selecting the right machinery tailored to their specific production needs, ensuring seamless integration into existing workflows.

Top 10 Benefits of Using an Automatic Wire Coiling Machine for Your Business

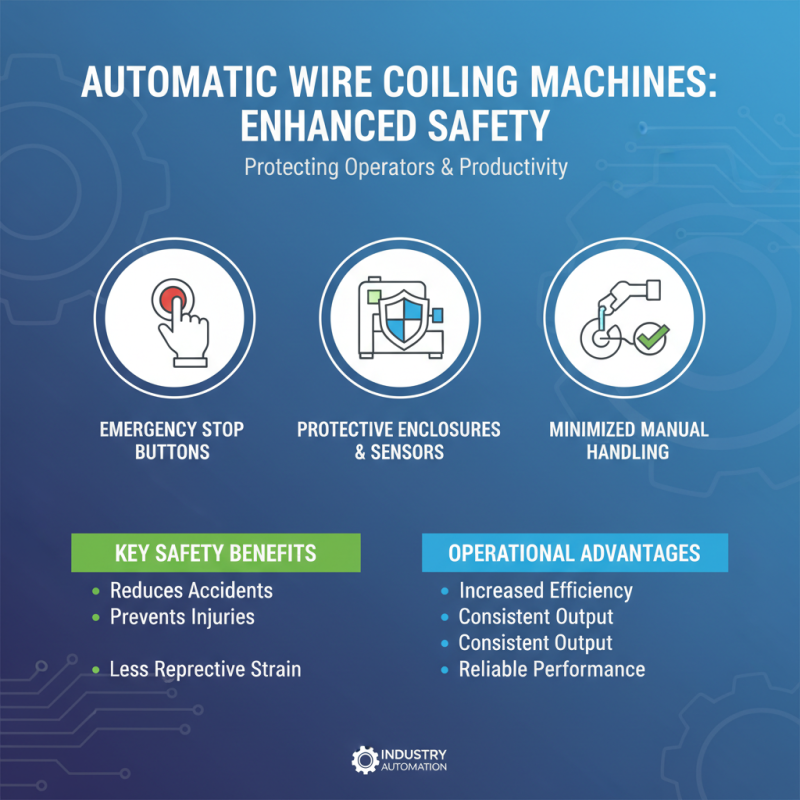

Enhanced Safety Features of Automatic Wire Coiling Machines

Automatic wire coiling machines are equipped with advanced safety features that significantly enhance operational safety in industrial settings. These machines often come with emergency stop buttons, protective enclosures, and sensors that detect obstructions. Such safety measures ensure that operators can work without the constant worry of potential accidents, reducing the likelihood of injuries. Furthermore, the automation process minimizes manual handling of wires, which can often lead to repetitive strain injuries and other workplace hazards.

In addition to physical safeguards, many automatic wire coiling machines include software functionalities that monitor operations in real-time. This software can alert operators to any anomalies or malfunctions, allowing for quick interventions that prevent accidents. The integration of safety features not only protects employees but also enhances the overall efficiency of the production process. By creating a safer working environment, businesses can improve productivity and employee morale, ultimately leading to better outcomes for both workers and the organization.

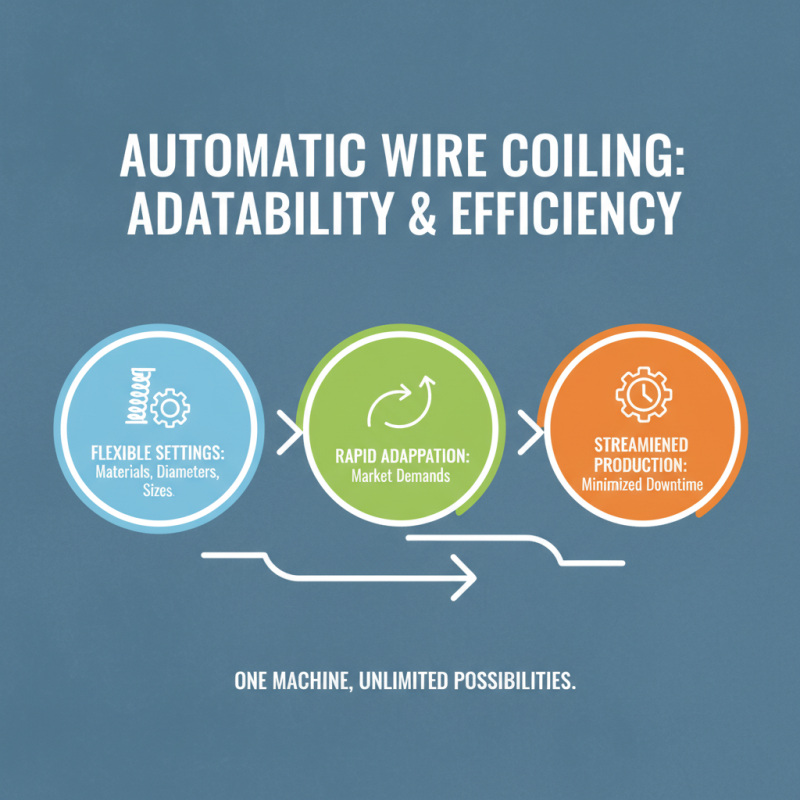

Flexibility and Customization Options for Diverse Wire Coiling Needs

When it comes to wire coiling, flexibility and customization are paramount for businesses looking to meet diverse customer needs. Automatic wire coiling machines offer a range of settings that can be adjusted to accommodate different wire materials, diameters, and coil sizes. This adaptability allows businesses to respond quickly to varying market demands, producing everything from delicate, fine wires to robust industrial coils without the need for multiple machines. This not only streamlines production processes but also minimizes downtime, making it easier to pivot and adapt to new projects as they arise.

Moreover, these machines often come with advanced programming capabilities that enable users to customize coil shapes and patterns with precision. This level of customization ensures that businesses can create specialized products that cater to particular applications or client specifications, enhancing their competitive edge. With the ability to easily modify settings for different projects, companies can maintain high-quality outputs while reducing waste and optimizing resource use. By investing in an automatic wire coiling machine, businesses not only improve efficiency but also open the door to innovation in their product offerings, ultimately driving growth and customer satisfaction.

Related Posts

-

Top 10 Tips for Choosing the Best Automatic Coil Machine for Your Needs

-

What is an Auto Winding Machine? Exploring Efficiency and Precision in Coil Production

-

Essential Tips for Choosing the Right Motor Winding Machine for Your Needs

-

Top 2025 Coil Winding Machines Features Benefits and Buying Guide

-

What is a Coiling Machine and How Does it Work for Your Projects

-

How to Choose the Best Micro Coil Winding Machine for Your Needs