Top 10 Automatic Wire Coiling Machines for Efficient Production

In the rapidly evolving manufacturing landscape, efficiency and precision are paramount, particularly in the production of wire products. An automatic wire coiling machine has emerged as an essential tool for manufacturers aiming to enhance their operational capabilities. These machines not only streamline the coiling process but also ensure uniformity and quality in the production of various wire forms. With the increasing demand for wire in diverse industries, the significance of investing in advanced coiling technology cannot be overstated.

This guide explores the top 10 automatic wire coiling machines currently available in the market, evaluating their features, functionalities, and the benefits they bring to production lines. Each machine is designed to cater to different production needs, making it crucial for manufacturers to select the right one to improve efficiency while reducing labor costs. As we delve into the specifics of these machines, we will highlight their innovative designs and the cutting-edge technology that sets them apart in a competitive landscape. Ultimately, the goal is to provide valuable insights that empower manufacturers to make informed decisions in their quest for operational excellence.

Overview of Automatic Wire Coiling Machines

Automatic wire coiling machines are essential for streamlining production processes in industries that rely on wire products. These machines are designed to efficiently coil wire into various shapes and sizes, significantly reducing labor costs and increasing output. By automating the coiling process, manufacturers can ensure uniformity and precision, leading to higher quality products. Furthermore, these machines often come equipped with advanced features such as programmable controls and sensors that enhance their functionality and adaptability to different wire types.

When selecting an automatic wire coiling machine, it’s important to consider factors such as speed, maximum coil size, and ease of operation. Additionally, maintenance requirements should not be overlooked; regular servicing can prevent costly downtimes and prolong the machine's lifespan.

**Tips:** Always consult the technical specifications before making a purchase to ensure the machine meets your production needs. Investing in a machine with user-friendly controls can also save time during training and operation. Finally, consider reaching out to different suppliers to compare features and pricing, which can help in making an informed decision.

Key Features to Consider When Choosing a Coiling Machine

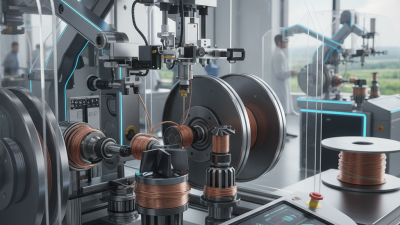

When selecting an automatic wire coiling machine, several key features should be carefully considered to ensure optimal efficiency and productivity. First and foremost, the machine's coiling speed plays a crucial role in determining overall output. A higher coiling speed allows for quicker production cycles, which can significantly reduce lead times and enhance competitiveness in the manufacturing process. Additionally, the ability to adjust coiling diameters and wire thicknesses can provide flexibility for handling a variety of projects, catering to the specific demands of different industries.

Another important feature to evaluate is the machine's automation capabilities. Advanced models may come equipped with programmable logic controllers (PLCs) and touchscreen interfaces, allowing for seamless operation and easy adjustments. This automation not only streamlines the workflow but also minimizes human error, resulting in consistent quality and reduced material waste.

Moreover, consider the machine's maintenance requirements; a design that facilitates easy access for routine maintenance tasks can enhance longevity and minimize downtime, ultimately contributing to a more efficient production environment.

Top Manufacturers of Automatic Wire Coiling Machines

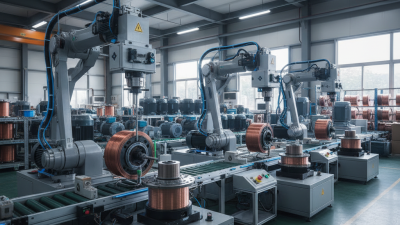

When it comes to selecting an automatic wire coiling machine, it is essential to consider the top manufacturers that contribute significantly to the industry. These manufacturers have invested heavily in technology and innovation, ensuring that their machines deliver superior performance and efficiency. They utilize advanced engineering techniques and materials, which result in machines that are not only reliable but also capable of adapting to various production requirements.

The expertise of leading manufacturers often translates into the development of user-friendly interfaces and automated features that enhance production processes. They also prioritize safety and durability, equipping their machines with features that protect operators and extend the lifespan of the equipment. As businesses continue to seek ways to optimize their production lines, partnering with reputable manufacturers remains a strategic move for companies looking to improve their output and maintain a competitive edge in the market.

Top 10 Automatic Wire Coiling Machines Production Capacity

Comparison of Performance and Efficiency Among Leading Models

In the ever-evolving landscape of wire processing, automatic wire coiling machines stand out as pivotal assets for manufacturers striving for efficiency and productivity. Recent industry reports indicate that automated systems significantly enhance production speed, reducing manual labor and minimizing errors. According to a study by Market Research Future, the automatic wire coiling machine market is expected to grow at a CAGR of 5.8% from 2021 to 2027, driven by the increasing need for high-volume wire products across various sectors including automotive and electronics.

When comparing the performance and efficiency of leading automatic wire coiling machines, key metrics such as cycle time, precision, and energy consumption come into play. Models equipped with advanced servo motors tend to deliver superior speed and accuracy, often achieving cycle times as low as 15 seconds per coil. Additionally, energy-efficient designs have been recognized for reducing operational costs without compromising output quality. A report from Technavio suggests that energy costs for wire production can be reduced by up to 20% when utilizing the latest advancements in machine technology, showcasing the dual benefits of economic and environmental efficiencies in the production process. This shift towards automation is not merely a trend but a necessary evolution for manufacturers aiming to stay competitive in a global marketplace.

Top 10 Automatic Wire Coiling Machines for Efficient Production - Comparison of Performance and Efficiency Among Leading Models

| Model | Coiling Speed (m/min) | Max Wire Diameter (mm) | Automatic Features | Energy Consumption (kWh) | User Rating (out of 5) |

|---|---|---|---|---|---|

| Model A | 50 | 3.0 | Fully Automatic, Touchscreen Controls | 1.2 | 4.5 |

| Model B | 65 | 2.5 | PLC Integration, Data Logging | 1.0 | 4.7 |

| Model C | 45 | 4.0 | Auto Cutting, Coil Counting | 1.5 | 4.2 |

| Model D | 55 | 3.5 | Servo Motors, Wi-Fi Connectivity | 1.1 | 4.6 |

| Model E | 70 | 2.0 | High-Speed Operations, Safety Sensors | 0.9 | 4.8 |

| Model F | 40 | 5.0 | Programmable Settings, Remote Monitoring | 1.4 | 4.1 |

| Model G | 60 | 2.5 | Multi-Coil Production, Speed Adjustment | 1.3 | 4.4 |

| Model H | 75 | 1.5 | User-Friendly Interface, Efficient Cooling | 0.8 | 4.9 |

| Model I | 30 | 4.5 | Compact Design, Easy Transport | 1.6 | 3.8 |

| Model J | 85 | 2.0 | Advanced Robotics, High Precision | 0.7 | 5.0 |

Future Trends in Wire Coiling Technology and Automation

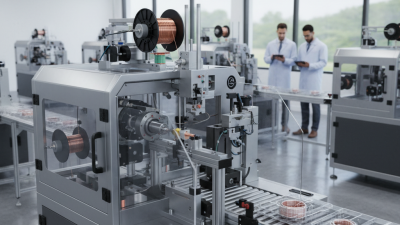

The future of wire coiling technology is poised for significant advancement, driven by automation and the integration of smart technology. As industries demand higher efficiency and precision, automatic wire coiling machines are evolving to meet these challenges. Innovative features such as real-time monitoring systems and advanced robotics are enhancing the accuracy of coil production while minimizing human intervention. This trend not only streamlines workflows but also significantly reduces production times, making it easier for manufacturers to keep up with the rapidly changing market demands.

Moreover, the incorporation of artificial intelligence and machine learning into wire coiling machinery is reshaping the landscape of production. These technologies allow for predictive maintenance, enabling machines to anticipate failures before they occur, thus reducing downtime. Additionally, data analytics capabilities are facilitating better control over manufacturing processes, enabling operators to make informed decisions that lead to a more efficient production line. As these trends continue to develop, the wire coiling industry will likely see a shift towards more sustainable practices, minimizing waste and energy consumption while maximizing output.

Related Posts

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide

-

2025 Top Spindle Winding Machine Innovations and Buying Guide

-

10 Best Motor Winding Coil Machines for Efficient Production in 2023

-

Top 10 Spindle Winding Machines for Efficient Production in 2023

-

How to Choose the Best Automatic Coil Winding Machine for Your Business Needs

-

How to Choose the Best Micro Coil Winding Machine for Your Needs