Auto Winding Machine Tips for Efficient Operation and Maintenance Guide

In the fast-paced world of manufacturing, the efficiency of production processes can significantly impact a company's bottom line. One pivotal element in the realm of textile and wire production is the auto winding machine, designed to automate the winding process and enhance productivity. According to industry expert Dr. Mark Jensen, "The key to optimizing an auto winding machine lies in understanding its intricacies and maintaining it diligently." This sentiment underscores the importance of effective operation and maintenance strategies that can prolong machine life while maximizing output.

As businesses strive to remain competitive, understanding the nuances of auto winding machines becomes essential. From routine maintenance checks to troubleshooting common issues, there are best practices that every operator should follow. The integration of technology in modern auto winding machines has made them increasingly efficient, but these advancements require a knowledgeable workforce that can adapt to their evolving functionalities. In this guide, we will delve into critical tips for operating and maintaining auto winding machines effectively, ensuring that your production line runs smoothly and efficiently.

Understanding Auto Winding Machines: Principles of Operation

Auto winding machines are essential tools in various industries, particularly for efficiently producing coils and wires. Understanding their principles of operation is crucial for maximizing productivity and ensuring quality. These machines work by automating the winding process, where a continuous length of wire is looped around a core to create coils. The automation reduces manual labor, speeds up production, and minimizes errors, making it vital to grasp the fundamental mechanisms at play.

When operating an auto winding machine, efficiency can be significantly improved by following a few key tips. First, ensure that all components are regularly lubricated and maintained to prevent wear and tear. This maintenance helps maintain smooth operation and extends the machine's lifespan. Additionally, calibrate the machine before starting production runs to ensure that the winding tension and speed are set correctly, which can prevent defects in the finished coils.

Another important aspect of efficient operation is training personnel thoroughly on how to operate the machine correctly. By investing time in training, operators can quickly identify potential issues and resolve them before they escalate, further improving the overall efficiency of the winding process. Regular training sessions can instill best practices and keep the team updated on any new operational techniques, contributing to a highly productive manufacturing environment.

Key Components of Auto Winding Machines and Their Functions

Auto winding machines are essential in the textile and manufacturing industries, primarily designed to efficiently reel or wind materials onto spools. Understanding the key components of these machines allows operators to optimize their performance and ensure longevity. Key components include the drive system, tension control mechanisms, and winding heads. The drive system powers the operation, converting electrical energy into motion. Meanwhile, the tension control is crucial for maintaining consistent tension in the material, preventing defects, and ensuring a smooth winding process. Finally, winding heads are responsible for the actual winding action, and their design can significantly impact the quality of the output.

To achieve efficient operation, it is essential to regularly maintain these components. Conduct routine checks on the drive system to ensure it operates smoothly without overheating. Adjust the tension settings based on the type of material being wound, as too little or too much tension can lead to issues like slippage or breakage. Additionally, keeping the winding heads clean and well-lubricated will enhance their performance and prolong their lifespan.

Implementing these tips not only facilitates smooth daily operations but also reduces downtime for repairs, ultimately leading to increased productivity and cost savings in the long run. Taking the time to understand and maintain these key components can significantly impact the overall efficiency of your auto winding machine.

Best Practices for Efficient Operation of Auto Winding Machines

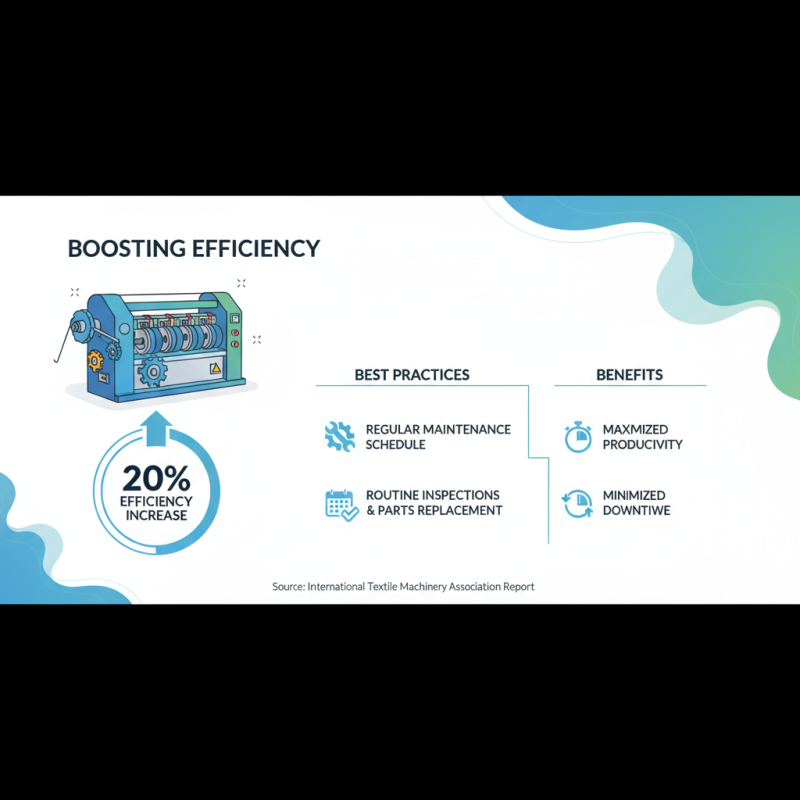

When it comes to the efficient operation of auto winding machines, adhering to best practices is crucial for maximizing productivity and minimizing downtime. A recent industry report from the International Textile Machinery Association revealed that proper maintenance and operational procedures can lead to a 20% increase in overall machine efficiency. One key best practice is implementing a regular maintenance schedule, which includes routine inspections and timely replacement of worn-out parts. This approach not only extends the machine's lifespan but also ensures consistent performance.

Another vital aspect is operator training. Skilled operators who understand the nuances of the machines can significantly reduce the incidence of errors and accidents. According to a study by the Manufacturing Institute, organizations that invest in training programs experience a 30% reduction in operational mishaps. Additionally, fostering an environment of continuous improvement encourages operators to share insights and suggestions, leading to innovative solutions that further enhance efficiency. By prioritizing these practices, manufacturers can achieve optimal performance and a competitive edge in the market.

Routine Maintenance Tips for Longevity of Auto Winding Machines

Routine maintenance is crucial for the longevity of auto winding machines, as it ensures optimal performance and reduces the risk of costly downtime. According to a report by the International Journal of Advanced Manufacturing Technology, a well-maintained machine can improve operational efficiency by up to 15%. This highlights the importance of establishing a regular maintenance schedule that includes lubrication of moving parts, inspection of electrical connections, and alignment checks. Ensuring that the machines are operated within their specified parameters can further prevent unnecessary wear and tear.

In addition to mechanical upkeep, monitoring environmental conditions is equally important. Auto winding machines perform best in humidity-controlled environments, as excessive moisture can lead to rust and deterioration of electrical components. The American Society for Quality states that implementing a humidification system can extend the lifespan of industrial machinery by approximately 25%. Regular training for operators on best practices in maintenance and operation can also contribute significantly to machine longevity, reducing the incidence of accidents and errors that may lead to costly repairs. Prioritizing these maintenance strategies will not only enhance the performance of auto winding machines but also lead to significant savings in operational costs over time.

Auto Winding Machine Tips for Efficient Operation and Maintenance Guide

| Maintenance Tip | Frequency | Benefit | Notes |

|---|---|---|---|

| Clean Machine Components | Weekly | Prevents Dust Build-up | Use appropriate cleaners and tools |

| Lubricate Moving Parts | Monthly | Reduces Friction | Follow manufacturer recommendations |

| Check Electrical Connections | Quarterly | Ensures Safety and Performance | Look for signs of wear or corrosion |

| Replace Worn Parts | As Needed | Maintains Machine Efficiency | Keep spare parts available |

| Review Operating Conditions | Monthly | Optimizes Performance | Adjust environment if necessary |

Common Issues and Troubleshooting Techniques for Auto Winding Machines

When operating auto winding machines, encountering issues is not uncommon. Common problems include inconsistent winding tension, which can lead to defects in the final product. To troubleshoot this, begin by checking the tension settings and ensuring they are aligned with the specific material being used. It may also be helpful to inspect the tension control components for wear or damage, as these can significantly affect the winding quality.

Another frequent issue is misalignment of the winding path. This can cause uneven layers and create difficulties in the overall operation. To address misalignment, regularly inspect the machine's guides and adjust them as necessary to ensure that the material is fed evenly. Additionally, cleaning components that may disrupt the path can help maintain smooth operation. Regular preventive maintenance, including lubrication of moving parts, will help to minimize these issues and enhance the longevity of the machine.

Related Posts

-

What is an Auto Winding Machine? Exploring Efficiency and Precision in Coil Production

-

Top 5 Motor Stator Winding Machines for Efficient Coil Production

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

5 Essential Tips for Choosing the Right Wire Winding Machine: Boost Efficiency by 30%

-

Top 10 Automatic Wire Coiling Machines for Efficient Production

-

What is a Coiling Machine and How Does it Work for Your Projects