What is an Auto Winding Machine? Exploring Efficiency and Precision in Coil Production

In the ever-evolving landscape of manufacturing, the significance of precision and efficiency cannot be overstated. Among the remarkable innovations in this domain is the auto winding machine, a pivotal tool in coil production. Renowned industry expert Dr. Emily Carter, a leading researcher in advanced manufacturing technologies, aptly stated, "The development of the auto winding machine has revolutionized the way we approach coil production, enabling faster and more accurate results." This sentiment underscores the machine's critical role in optimizing both production speed and quality.

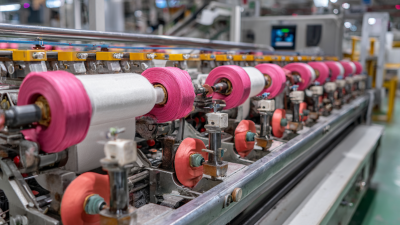

The auto winding machine automates the winding process, reducing human error and increasing consistency in coil design. With the ability to cater to various specifications, these machines are tailored for diverse applications, from electronics to automotive components. As industries strive for higher productivity, the integration of such innovative technology is becoming imperative.

Furthermore, as manufacturers face increasing demand for high-quality products, the auto winding machine stands out as a key player in enhancing operational efficiency. This exploration into the workings and benefits of auto winding machines will shed light on how they are shaping the future of manufacturing processes and their undeniable impact on productivity and precision.

Understanding the Basics of Auto Winding Machines in Coil Production

Auto winding machines play a crucial role in coil production, particularly in industries such as electronics, automotive, and renewable energy. These machines are designed to efficiently and precisely wind wire into coils, which are essential components in transformers, inductors, and various electrical devices. According to a recent industry report, the market for auto winding machines is projected to grow at a CAGR of 5.2% from 2023 to 2030, driven by the increasing demand for automation and precision in manufacturing processes.

The fundamentals of auto winding machines involve intricate mechanisms that ensure uniform tension and precision winding. They utilize advanced technologies like servo motors and digital controls to enhance accuracy and efficiency. A well-calibrated winding machine can minimize defects and material waste, ultimately leading to higher quality products and reduced production costs. In fact, studies have shown that automated winding processes can increase productivity by up to 30% compared to manual methods.

Tips: To ensure optimal performance of auto winding machines, regularly calibrate the equipment and perform routine maintenance checks. Additionally, investing in high-quality wire materials can significantly improve the overall winding quality and enhance the longevity of the coils produced. Moreover, training operators on the latest technologies and techniques can further boost efficiency in coil production.

The Technology Behind Efficient Auto Winding Processes

Auto winding machines have revolutionized the production of coils by harnessing advanced technologies that prioritize both efficiency and precision. The core of these machines lies in their ability to automate the winding process, significantly reducing human error and enhancing output. Utilizing sophisticated algorithms and real-time monitoring, these machines can adjust the winding tension, speed, and layering in response to the specifics of the material and design, thereby ensuring a consistent quality of coils that meet stringent specifications.

Moreover, the integration of smart sensors and data analytics further amplifies the efficacy of auto winding machines. These technologies not only facilitate optimal performance but also provide valuable feedback for maintenance and operational improvements. By analyzing data collected during the winding process, manufacturers can identify patterns, predict potential issues, and optimize workflows, ultimately leading to reduced waste and increased profitability. The ongoing advancements in automation and connectivity continue to shape the landscape of coil production, making auto winding machines indispensable in modern manufacturing.

Benefits of Auto Winding Machines for Precision Coil Fabrication

Auto winding machines have revolutionized the process of coil fabrication, delivering unparalleled precision and efficiency that traditional winding methods struggle to achieve. These machines utilize advanced technology to automate the winding process, ensuring that each coil is produced with consistent quality. This automation not only minimizes human error but also enhances production speed, allowing manufacturers to meet larger demands without compromising on accuracy.

The benefits of auto winding machines extend beyond mere efficiency. Their precision in winding leads to improved performance of the coils themselves, which is crucial in various applications, from electrical transformers to motors. Moreover, by reducing material waste through optimized winding techniques, these machines contribute to cost savings for manufacturers. The ability to program different winding patterns easily also allows for greater flexibility in production, enabling companies to adapt swiftly to varied client requirements and market trends. Hence, the adoption of auto winding machines is a significant stride towards achieving superior quality and reliability in coil fabrication.

Comparative Analysis: Auto Winding vs. Manual Winding Techniques

Auto winding machines and manual winding techniques serve the same critical purpose in coil production, yet they differ significantly in terms of efficiency and precision. Auto winding machines utilize automated processes to create coils at a faster rate with minimal human intervention. This automation ensures consistent tension and uniformity in the winding process, which is crucial for high-quality output. In industries where large quantities of coils are required, the speed and reliability of auto winding machines prove to be a significant advantage, reducing labor costs and minimizing errors.

On the other hand, manual winding techniques, while often more labor-intensive, allow for greater flexibility and control over the winding process. Skilled operators can adjust their techniques based on specific requirements of a project, accommodating intricate designs and custom specifications. However, this method is susceptible to human error and variability, which can lead to inconsistencies in coil production. In essence, while auto winding machines excel in efficiency and repetitive precision, manual winding remains valuable for bespoke applications where craftsmanship is paramount. Each method has its unique strengths, and the choice between them depends on the specific needs of the production environment.

Efficiency Comparison: Auto Winding vs. Manual Winding Techniques

This chart illustrates the comparative analysis of auto winding and manual winding techniques based on two metrics: production speed and accuracy. The auto winding machine significantly outperforms manual winding in both categories.

Future Trends in Auto Winding Machine Innovations and Efficiency

The auto winding machine is a critical innovation in the field of coil production, especially with the increasing demand for efficiency and precision. As manufacturers strive to enhance productivity, future trends in auto winding machines are focusing on incorporating advanced technology such as artificial intelligence and machine learning. These innovations are set to optimize the winding process, resulting in significant reductions in material waste and production time. With smarter automation, these machines can learn from previous production runs to continuously improve their operations, ensuring high flexibility and adaptation to different coil specifications.

Moreover, the integration of IoT (Internet of Things) in auto winding machines is revolutionizing how data is collected and analyzed in real-time. This connectivity allows for predictive maintenance, which minimizes downtime and boosts overall equipment effectiveness. In addition to technological advancements, sustainability is becoming a central theme in the design of these machines. New eco-friendly materials and energy-efficient processes are being developed to not only meet regulatory standards but also appeal to environmentally conscious consumers. As these trends advance, the auto winding machine is positioned to play a pivotal role in the future of manufacturing, enhancing productivity while being mindful of environmental impact.

Related Posts

-

Top 5 Motor Stator Winding Machines for Efficient Coil Production

-

Revolutionizing Efficiency How Motor Winding Automatic Machines Transform Manufacturing

-

2025 Top 5 Used Coil Winding Machines You Need for Your Business

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide

-

How to Choose the Best Motor Coil Winding Machine for Your Needs in 2025

-

What is Automated Machine Learning Its Impact on Industry Growth and Efficiency