2026 Top Motor Winding Coil Machine Innovations and Trends?

The world of motor winding coil machines is rapidly evolving. Innovations in this field are crucial for various industries. They shape the future of electric motors and equipment. In 2026, we can expect exciting trends and advancements.

Companies are focusing on automation. They seek to improve efficiency and reduce errors. Advanced algorithms play a role in optimizing the winding process. This shift may lead to more precise coils. Enhanced technology could also lead to more user-friendly machines.

However, challenges remain. Manufacturers must balance automation with craftsmanship. Some processes may become too reliant on technology. This raises concerns about maintaining skilled labor. As we explore these trends, it is vital to reflect on their impact. The future of motor winding coil machines holds promise, but careful consideration is essential.

2026 Motor Winding Coil Machines: Overview of Innovations

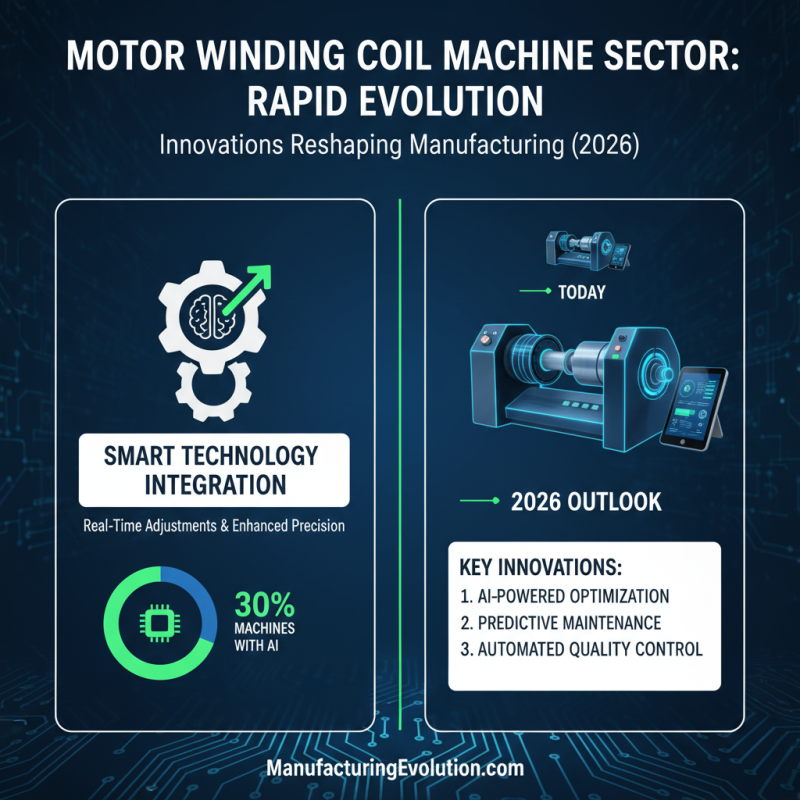

The motor winding coil machine sector is evolving rapidly. As of 2026, several innovations promise to reshape manufacturing processes. One significant trend is the integration of smart technology. Reports indicate that around 30% of machines now feature artificial intelligence. This allows for real-time adjustments and enhanced precision.

Furthermore, the push for sustainability drives technological advancements. Nearly 40% of new models focus on energy efficiency. This not only reduces operational costs but also minimizes environmental impact. However, the transition to greener technologies comes with challenges. Many manufacturers struggle with the upfront investment required.

Automation continues to gain traction as well. Utilizing robotics in winding processes improves efficiency. Yet, there are concerns about workforce displacement. Skills gaps may emerge, requiring training programs for existing employees. Balancing innovation with workforce stability will be crucial in the coming years.

Emerging Technologies in Motor Winding Coil Machinery for 2026

As we move toward 2026, innovations in motor winding coil machinery are gaining attention. Emerging technologies are redefining how these machines operate. For instance, advancements in automation and robotics are streamlining production processes. Reports indicate that automated coil winders can enhance efficiency by up to 30%. This is a significant shift for a sector that often relies on traditional methods.

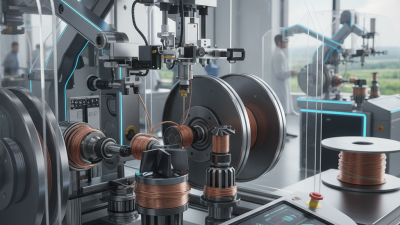

Moreover, smart technology integration is transforming these machines. Sensors and IoT devices allow for real-time monitoring. Data indicates that machines equipped with smart technology see a 15% reduction in operational downtime. However, integrating new technology is not without challenges. Many manufacturers face the need for skilled technicians to operate and maintain these advanced machines. This skills gap could slow down adoption rates in certain regions.

Sustainability is another crucial focus area. Eco-friendly machines are becoming essential. Reports show that energy-efficient models can cut energy consumption by up to 40%. Manufacturers are now faced with the dilemma of balancing cost with eco-friendly practices. It raises questions on long-term investments and their payoffs.

2026 Top Motor Winding Coil Machine Innovations and Trends

| Innovation/Trend | Description | Benefits | Projected Impact Year |

|---|---|---|---|

| Smart Coil Monitoring | Integration of IoT sensors for real-time monitoring of coil conditions. | Improved maintenance, reduced downtime. | 2026 |

| Automated Winding Systems | Fully automated machines that optimize winding techniques. | Increased production efficiency and consistency. | 2026 |

| Advanced Insulation Techniques | New materials and methods improving insulation properties. | Enhanced durability and performance of coils. | 2026 |

| Energy Efficient Motors | Development of motors with lower energy consumption. | Cost savings and reduced environmental impact. | 2026 |

| Hybrid Winding Strategies | Combining traditional and innovative winding techniques. | Greater flexibility in manufacturing processes. | 2026 |

Key Industry Trends Shaping Motor Winding Coil Machine Design

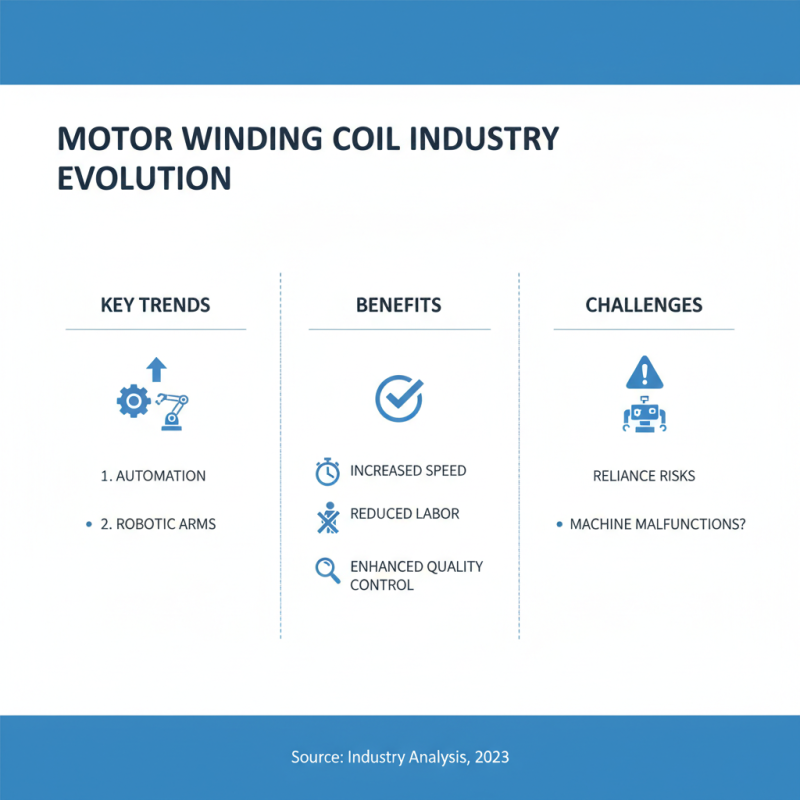

The motor winding coil machine industry is rapidly evolving. Innovations focus on efficiency and precision. One significant trend is automation. More machines now incorporate robotic arms. These innovations boost speed and reduce manual labor. This allows operators to focus on quality control. However, reliance on automation raises concerns. What if the machines malfunction?

Sustainability is another key factor. Manufacturers are increasingly adopting eco-friendly materials. This shift not only benefits the environment but also enhances brand image. Many companies explore energy-efficient processes as well. Yet, transitioning to greener practices can be costly and complex. Production lines may experience temporary disruptions.

Data integration is gaining traction, too. Advanced analytics can improve machine performance. Real-time monitoring is becoming the norm. Yet, such systems can be complicated to install. Employees may need extensive training. Change can be challenging for traditional manufacturers. There’s a balancing act between innovation and practicality. These trends shape the future of motor winding coil machines.

Efficiency Improvements in 2026 Motor Winding Coil Production

The production of motor winding coils is evolving rapidly. In 2026, efficiency improvements will play a vital role. According to a recent industry report, production efficiency could increase by 15% due to innovative technologies. Automation is leading this change. Machines are now capable of more precise winding processes. They can reduce material wastage significantly. This innovation addresses a critical pain point in the industry.

However, these advancements come with challenges. Many companies struggle to adapt to new technologies. Workforce training becomes essential. A report noted that 40% of companies face skill gaps. Investing in employee training can mitigate this issue. Another area of concern is the high initial cost of new machines. Budget constraints may hinder progress. Careful financial planning is necessary to overcome this barrier.

Tips: Regularly assess your production processes. Identify areas for improvement. Consider whether new technologies fit your operations. Seeking expert consultation can provide insights. Investing in R&D may also uncover more efficient practices. Stay informed about industry trends. An informed decision can lead to sustainable growth.

2026 Motor Winding Coil Production Efficiency Improvements

Sustainability Practices in Motor Winding Coil Manufacturing Innovations

Sustainability has become a major focus in motor winding coil manufacturing. Innovations aim to reduce environmental impact while enhancing efficiency. Reports indicate that the global market for sustainable manufacturing practices could reach $1 trillion by 2026. Yet, many companies still lag in implementing these practices.

One key trend is the use of eco-friendly materials. Biodegradable insulation films are gaining popularity. These materials reduce waste and energy consumption. Another innovation is energy-efficient machinery. This new equipment consumes up to 30% less energy than traditional models. While the benefits are clear, transitioning to these technologies can be costly. Many manufacturers hesitate to invest in new systems.

Recycling old coils is another emerging practice. Current data estimates that around 50% of manufacturing waste is recyclable. However, companies often overlook this potential. Poor recycling rates indicate a need for better systems and training. The drive for sustainability in these practices is essential. Without it, the industry may fall behind in global eco-initiatives. There’s a need for continuous improvement and commitment to greener alternatives.

Related Posts

-

10 Best Motor Winding Coil Machines for Efficient Production in 2023

-

Revolutionizing Efficiency How Motor Winding Automatic Machines Transform Manufacturing

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide

-

2025 Top Spindle Winding Machine Innovations and Buying Guide

-

Top 10 Spindle Winding Machines for Efficient Production in 2023

-

Top 10 Automatic Wire Coiling Machines for Efficient Production