2026 Best Motor Winding Coil Machine Options for Efficient Production?

In the ever-evolving landscape of manufacturing, selecting the best motor winding coil machine is crucial for efficiency. Industry expert, John Smith, notes, “The right machine can significantly enhance production speed and quality.” This insight underscores the importance of making informed choices in this sector.

Choosing a motor winding coil machine involves understanding specific production needs. Manufacturers must consider factors such as coil size, wire type, and automation levels. Not all machines are created equal, and some may falter in meeting unique requirements. This inconsistency can lead to costly errors and reduced output.

Furthermore, integrating new machines may require an adjustment period for operators. Training is necessary to maximize the potential of the motor winding coil machine. Manufacturers should anticipate some challenges and be prepared to address them. Overall, investing time in research can lead to superior production capabilities and long-term success.

Overview of Motor Winding Coil Machines in 2026

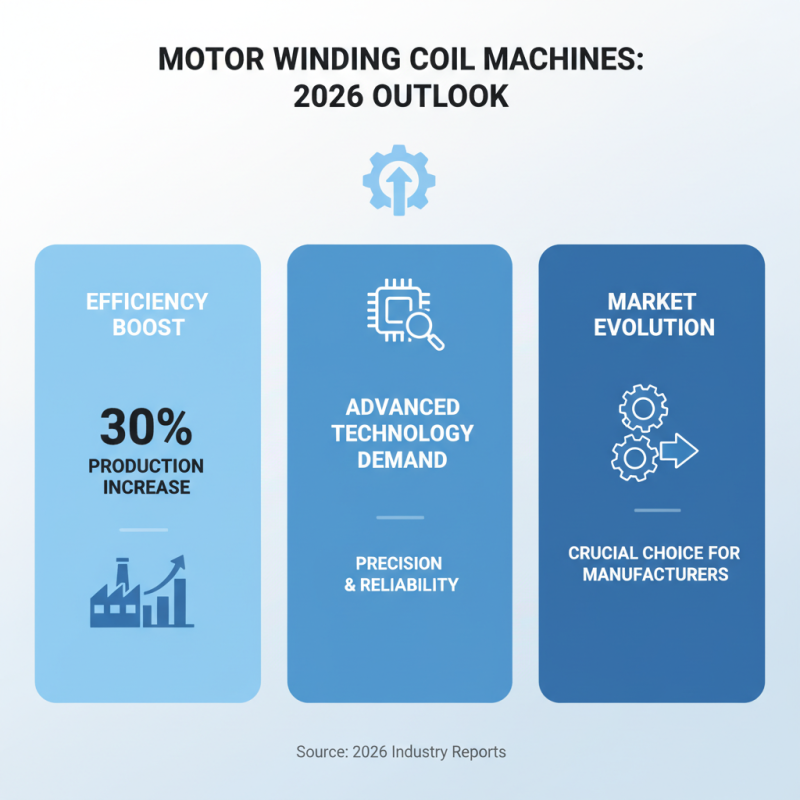

In 2026, the motor winding coil machine market is poised for significant advancements. As industries prioritize efficiency, these machines are becoming vital for production. Reports indicate that motor winding machines can improve productivity by up to 30%. They reduce the labor required and enhance precision. This shift is crucial for manufacturers seeking competitive edges.

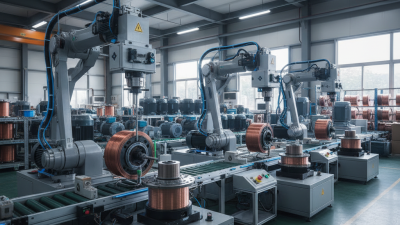

The latest technology in these machines often incorporates automation. Automated winding processes minimize human error and speed up production cycles. However, many companies still rely on outdated models. These machines consume more energy and generate more waste. According to recent studies, nearly 40% of manufacturers have not updated their equipment in over a decade. This gap presents an opportunity for innovation and reflection.

Environmental concerns are also rising. Energy-efficient machines are preferred by both consumers and regulatory bodies. Industry data suggests that a switch to smarter technologies can cut energy usage by up to 25%. Investments in advanced motor winding coil machines are essential. Emphasizing sustainability will shape the future landscape of production.

Key Features to Consider When Choosing Winding Coil Machines

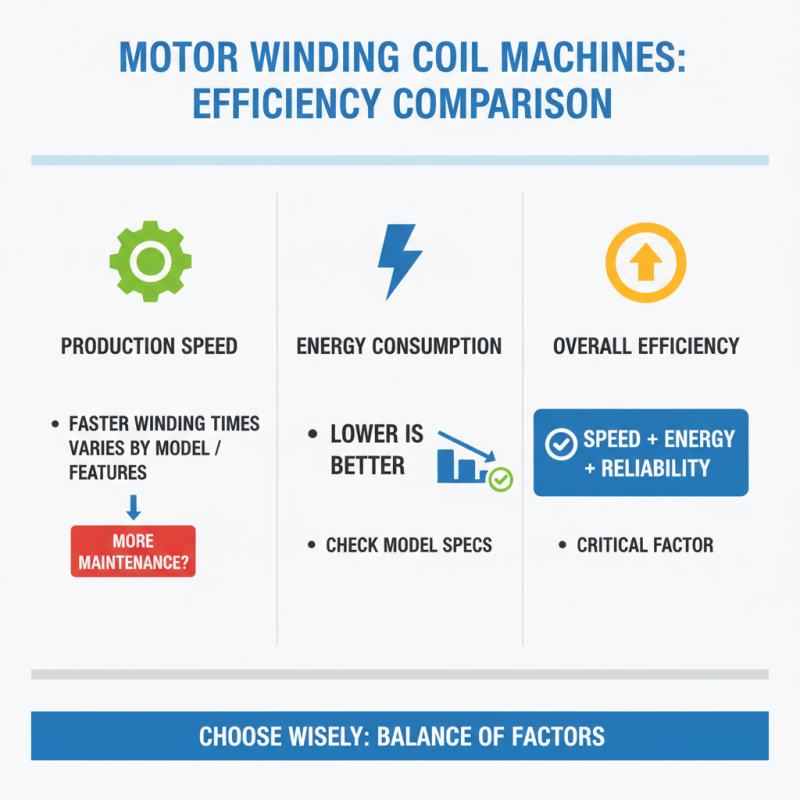

When selecting a winding coil machine, there are several key features to consider. One crucial aspect is the machine's winding speed. Higher speeds can increase output, but may compromise precision. A careful balance is necessary. Additionally, consider the machine's adaptability for different coil types. It should handle various wire sizes and materials effortlessly. Flexibility in design can lead to improved production efficiency.

Another important feature is the user interface. A machine with an intuitive interface can streamline operations. This can minimize training time for new operators. However, be wary of overly complex systems that could lead to operational errors. Simplicity often yields better results. Lastly, assess the machine's maintenance requirements. Frequent downtime for repairs can disrupt production. A reliable machine reduces long-term costs.

While these features guide your choice, reflect on your specific production needs. Not all machines fit every application perfectly. It’s essential to weigh the pros and cons of each option available. Understanding your goals will help in making a more informed decision.

2026 Best Motor Winding Coil Machine Options for Efficient Production

| Model | Max Coil Diameter (mm) | Wind Speed (RPM) | Control Type | Price Range (USD) | Energy Efficiency Rating |

|---|---|---|---|---|---|

| Model A | 150 | 3000 | Automatic | $15,000 - $20,000 | A+ |

| Model B | 200 | 2500 | Semi-Automatic | $10,000 - $15,000 | B |

| Model C | 100 | 3500 | Manual | $8,000 - $12,000 | C |

| Model D | 250 | 2200 | Fully Automatic | $25,000 - $30,000 | A++ |

Top Brands for Motor Winding Coil Machines in 2026

In 2026, choosing the right motor winding coil machine is crucial for manufacturers. Industry reports indicate that efficient machinery can enhance production rates by 30%. The demand for advanced technology in this sector is increasing. As the market evolves, manufacturers seek machines that offer precision and reliability.

Top machine brands focus on automation and ease of use. For instance, machines with programmable features allow users to customize winding patterns easily. This flexibility caters to various production needs. Some analytical reports suggest that companies utilizing automated winding machines see a significant drop in labor costs. Yet, there's a concern over the initial investments required for these technologies.

Moreover, data shows that maintenance of these machines often gets overlooked. A well-maintained machine can last significantly longer, impacting overall production efficiency. Operators frequently need more training on advanced equipment. Ignoring this aspect could lead to inefficiency and increased downtime. As technology progresses, companies must adapt and continuously improve their systems.

Comparison of Efficiency and Production Costs Among Machine Options

When comparing motor winding coil machines, efficiency is a critical factor. Different models offer various features that impact production speed. Some machines promise faster winding times but may require more maintenance. Users should consider not just the speed but also the energy consumption of each machine.

Production costs also vary significantly among options. While cheaper machines might save initial investments, they can lead to higher operational costs over time. Spare parts for some machines can be expensive and hard to find. Maintenance costs may outweigh savings gained from buying low-cost machines.

Market research is vital. Many users report unexpected downtime with specific machine types. Gathering user feedback could provide insights into reliability. Analyzing overall costs ensures a more informed decision. Careful consideration of both efficiency and costs can lead to better production outcomes.

Future Trends in Motor Winding Coil Machine Technology

The future of motor winding coil machine technology is exciting and full of possibilities. As industries evolve, the demand for efficient production solutions increases. Automation is at the forefront of this transformation. Machines are becoming smarter and more user-friendly. They feature advanced sensors and real-time monitoring. This ensures precision in winding processes.

Sustainability is also trending. Manufacturers are focusing on energy-efficient machines. These innovations can reduce waste and lower operational costs. However, this transition poses challenges. Not all companies can afford these advanced technologies. Training staff to use new systems is another hurdle. Finding a balance between tradition and innovation is crucial.

Customization will play a pivotal role in the coming years. Machines that can adapt to specific production needs will gain traction. Customers have unique requirements, and one size rarely fits all. Embracing change while considering existing practices may be tough. Reflection on past experiences is essential for improvement. Balancing progress with practicality ensures a more efficient future in motor winding coil production.

2026 Best Motor Winding Coil Machine Options for Efficient Production

Related Posts

-

What is a Coiling Machine and How Does it Work for Your Projects

-

10 Best Motor Winding Coil Machines for Efficient Production in 2023

-

2026 Top Motor Winding Coil Machine Innovations and Trends?

-

What is an Auto Winding Machine? Exploring Efficiency and Precision in Coil Production

-

Essential Tips for Choosing the Best Motor Coil Winding Machine

-

How to Choose the Best Micro Coil Winding Machine for Your Needs