2026 Top Automatic Wire Winding Machine Innovations and Trends?

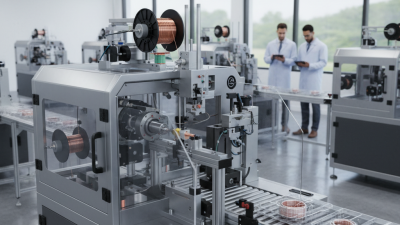

The automatic wire winding machine plays a vital role in various industries. As technology advances, its design and functionality evolve. The year 2026 promises remarkable innovations in this field.

Recent trends indicate a shift toward automation and precision. Manufacturers seek ways to enhance efficiency. New features may include smarter interfaces and better control systems. These innovations aim to reduce human error and increase productivity. However, some machines still struggle with adaptability.

Not all progress comes easy. Integrating advanced technologies can be complex. Manufacturers must find a balance between automation and manual oversight. This ongoing challenge raises questions about future developments. The upcoming advancements in automatic wire winding machines will shape the industry significantly.

Overview of Wire Winding Machines in 2026

In 2026, the landscape of wire winding machines shows remarkable advancements and trends. These machines are no longer just about winding wires. They now integrate smart technology for better efficiency. The automation is increasing, allowing for more precise control over the winding process. Manufacturers are focusing on user-friendly interfaces that simplify operation.

However, not all innovations are flawless. While automation boosts productivity, it raises concerns about the loss of skilled labor. The reliance on technology can lead to operational challenges when technical issues arise. Additionally, there’s a growing need for sustainability in machine design. Many manufacturers are experimenting with eco-friendly materials. This shift is commendable, but it needs more widespread adoption.

Customization options are expanding, and users can tailor their machines to specific needs. This flexibility is crucial for various industries. Yet, not all solutions fit every requirement. Some machines still struggle with consistency in quality. These imperfections signal areas for improvement. Embracing feedback is essential for the future of wire winding technology.

2026 Top Automatic Wire Winding Machine Innovations and Trends

| Feature | Description | Innovation Type | Starting Price (USD) |

|---|---|---|---|

| Automatic Tension Control | Maintains consistent tension during winding operations | Mechanical | $5,000 |

| Programmable Winding Patterns | Allows customization of winding sequences for various applications | Software | $7,500 |

| Smart Sensor Integration | Utilizes sensors for real-time monitoring and adjustments | Technology | $10,000 |

| Energy Efficiency Features | Optimizes power usage during operation | Environmental | $6,500 |

| User-Friendly Interface | Intuitive controls and display for easy operation | Human Factors | $4,000 |

Key Innovations in Automatic Wire Winding Technology

The automatic wire winding industry is witnessing remarkable innovations. These advancements are enhancing efficiency and precision in production. One significant trend is the integration of smart technology. Many machines are now equipped with sensors to monitor performance in real-time. This data-driven approach can optimize winding processes and reduce waste.

Additionally, automation software is evolving. Operators can now easily program complex patterns and manage multiple machines simultaneously. This shift simplifies the operator's role but may require new skills. Continuous training is essential to keep up with these changes. Wire winding automation is also becoming more compact. Smaller machines can fit into tighter spaces while still delivering high performance.

Despite progress, challenges remain. Not all operators are comfortable with new technologies. There is a learning curve that some may struggle to overcome. Furthermore, initial costs for advanced machines can be a barrier for smaller businesses. Balancing innovation with accessibility is crucial for industry growth. As technology advances, companies must ensure that they adapt swiftly to stay competitive.

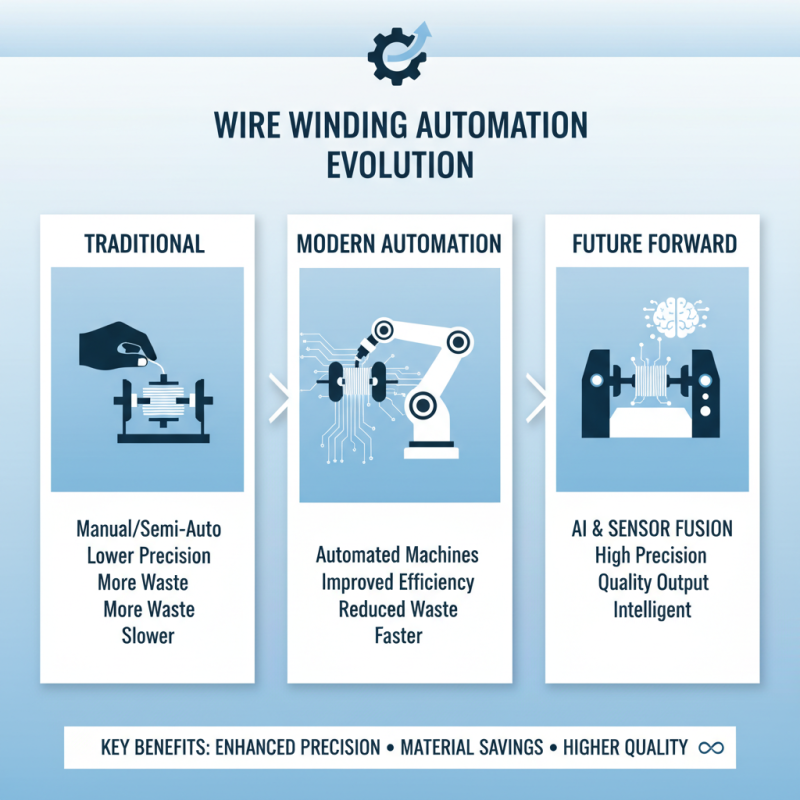

Trends Shaping the Future of Wire Winding Automation

The landscape of wire winding automation is evolving quickly. Innovations are reshaping how manufacturers approach wire winding processes. Automatic machines are becoming more intelligent and efficient. They incorporate advanced sensors and AI technology that enhance precision. This leads to reduced material waste and higher-quality output.

Trends are emerging that focus on sustainability and energy efficiency. As environmental concerns rise, manufacturers seek machines that consume less power. Designs are becoming more compact and versatile. This allows for flexibility in production lines. However, there are still challenges. Many companies struggle to integrate new technologies smoothly. Training staff on these innovations is often overlooked.

Collaboration among industry experts is crucial for future growth. Knowledge sharing can address common issues. A focus on user-friendly designs is necessary, too. Machines must be accessible for operators of varying skill levels. Investing in ongoing maintenance support is equally important. Regular updates and improvements can enhance longevity and efficiency. These elements are vital as the industry moves forward.

Impact of Industry 4.0 on Wire Winding Processes

The rise of Industry 4.0 is reshaping various sectors, including wire winding processes. Smart manufacturing is now a reality. Companies are integrating IoT devices into their machinery. These connections allow for real-time data monitoring and analysis. It helps in identifying inefficiencies that were previously unnoticed. However, full integration remains a challenge for many.

Automation in wire winding has advanced significantly. Predictive maintenance is a game-changer. Machines can now alert operators to potential failures before they happen. This reduces downtime and increases productivity. Yet, the learning curve for staff adapting to new technologies can be steep. Not all operators are ready for this shift. It's essential to invest in training to prepare the workforce.

Data analytics plays a crucial role in optimizing production lines. Companies can track performance metrics easily. However, interpreting this data requires skilled personnel. Misinterpretation could lead to poor decisions. The balance between automation and human oversight is delicate. While machines enhance efficiency, human intuition still plays a role in problem-solving.

Sustainability and Efficiency in Modern Wire Winding Solutions

In recent years, the wire winding industry has seen a major shift toward sustainability and efficiency. Manufacturers now focus on eco-friendly materials and processes. Energy consumption is a top concern, pushing for innovations that use less power without sacrificing performance. Modern machines prioritize not only productivity but also minimizing waste.

Tip: Consider investing in machines with energy-efficient motors. They can significantly reduce electricity costs over time. Also, explore the option of using biodegradable insulation materials.

Adopting automation is another trend. Automated winding machines reduce human error and increase precision. Still, they require careful oversight to maximize their potential. Operators need training to handle complex settings and troubleshooting. This highlights a growing need for skilled workers in the industry.

Tip: Regular maintenance is key to machine efficiency. Schedule routine inspections to prevent unexpected breakdowns. Remember, even the best machines can underperform without proper care. Embracing these trends can create a more sustainable future for wire winding solutions.

2026 Innovations in Automatic Wire Winding Machines

This chart illustrates the percentage improvements in sustainability and efficiency of modern wire winding solutions across various features such as energy consumption, waste reduction, and production speed.

Related Posts

-

How to Choose the Best Motor Coil Winding Machine for Your Needs in 2025

-

How to Choose the Best Programmable Coil Winding Machine for Your Needs

-

Top 2025 Coil Winding Machines Features Benefits and Buying Guide

-

What is the Best Automatic Winding Machine in 2026?

-

5 Essential Tips for Choosing the Right Wire Winding Machine: Boost Efficiency by 30%

-

How to Choose the Best Automatic Coil Winding Machine for Your Business Needs