2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide

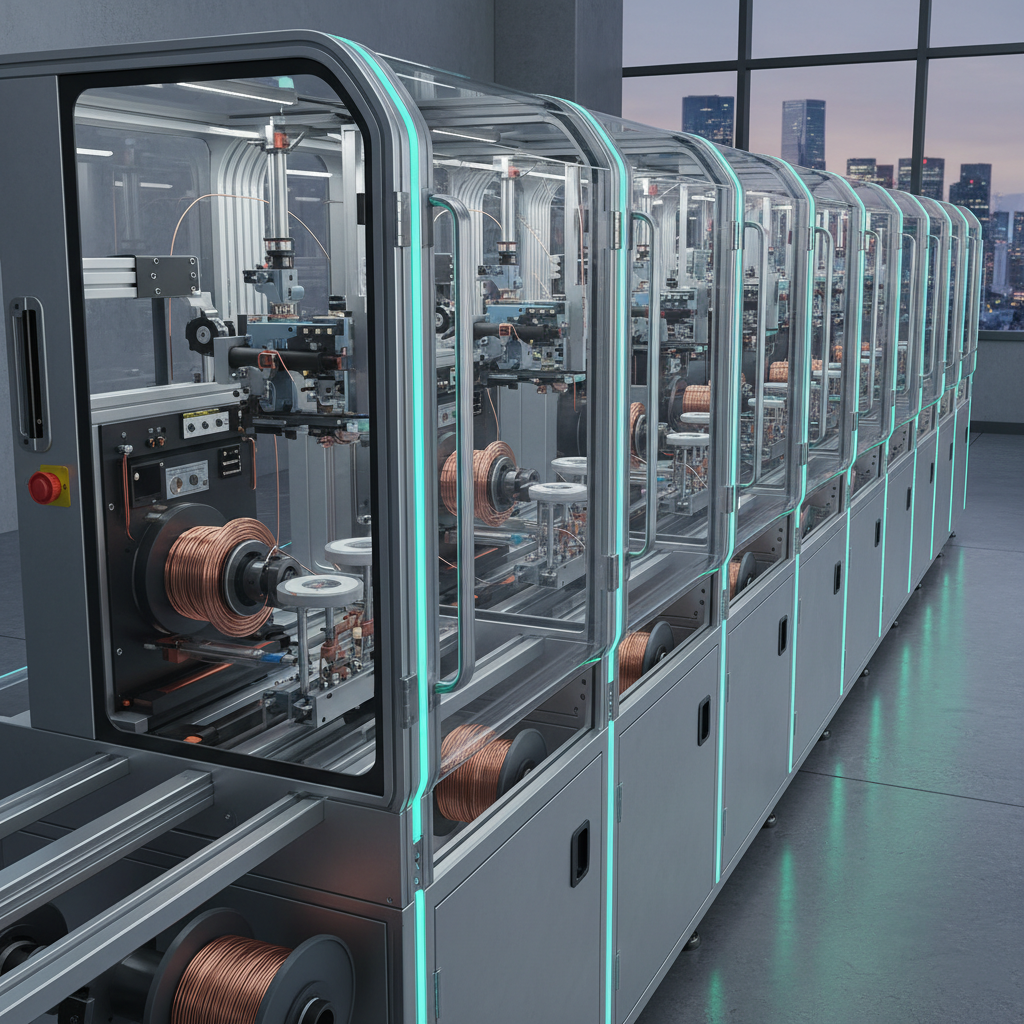

The manufacturing sector is continuously evolving, and among the key innovations driving efficiency and precision is the linear coil winding machine. As the demand for high-performance electric motors and transformers surges, driven by the proliferation of electric vehicles and renewable energy sources, the global market for coil winding machines is projected to reach $4.5 billion by 2025, according to recent industry reports. This growth underscores the importance of selecting the right equipment for optimal production capabilities, with linear coil winding machines taking center stage due to their unique advantages.

These machines offer significant benefits, including enhanced accuracy and reduced setup times, which are essential for meeting the stringent requirements of modern manufacturing. With features designed to streamline the winding process, such as advanced control systems and real-time monitoring, the top models on the market are ensuring consistent quality and increased throughput. In this article, we will explore the top 10 linear coil winding machines of 2025, detailing their features, benefits, and essential buying considerations to help manufacturers make informed decisions that align with their operational goals.

Top Features to Look for in Linear Coil Winding Machines

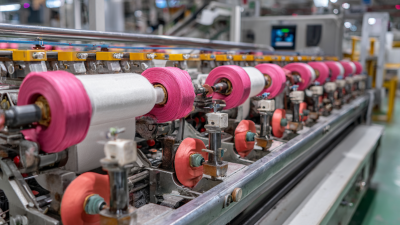

When considering the purchase of a linear coil winding machine, understanding the top features is essential for achieving optimal performance and efficiency. One of the primary attributes to look for is precision in winding. According to a report by MarketResearchFuture, machines that maintain high precision can reduce material waste by up to 20%. This is crucial not only for cost savings but also for enhancing the quality of the final product, particularly in industries where even minor inaccuracies can lead to significant performance issues.

Another important feature is the speed of operation. Modern linear coil winding machines can operate at speeds exceeding 1,500 rpm, as highlighted in the 2023 Industry Insights report. This speed not only improves productivity but also allows manufacturers to meet tight deadlines without compromising quality. Additionally, advanced control systems should be a priority, providing operators with real-time feedback and adjustments. This capability can enhance the versatility of the machine, allowing it to easily switch between different winding patterns and sizes, which is vital in the fast-evolving markets of electronics and automotive components.

2025 Top 10 Linear Coil Winding Machines

This chart displays the key features and benefits of the top 10 linear coil winding machines for 2025. The features include winding speed, precision, versatility, and energy efficiency, measured in relative units based on industry standards.

Key Benefits of Using Linear Coil Winding Technology

Linear coil winding technology has emerged as a pivotal advancement in various industries, particularly with the anticipated escalations in humanoid robot production and superconducting magnet development. This methodology enhances production efficiency, ensuring that manufacturers can meet the growing demands of modern applications. According to industry reports, implementing linear coil winding machines can improve output rates by up to 30% compared to traditional winding techniques, which is crucial as businesses prepare for increased automation in 2025.

Furthermore, the benefits of linear coil winding technology extend beyond just efficiency. These machines offer superior precision, leading to higher quality components essential for critical applications such as electromagnets used in future collider technologies. Research indicates that precision in winding can contribute to a 20% reduction in material waste, promoting sustainability in manufacturing processes. As companies like Tesla explore advanced robotics and next-generation superconducting applications, adopting linear coil winding can significantly enhance their production capabilities and reduce costs.

A Comprehensive Buying Guide for Linear Coil Winding Machines

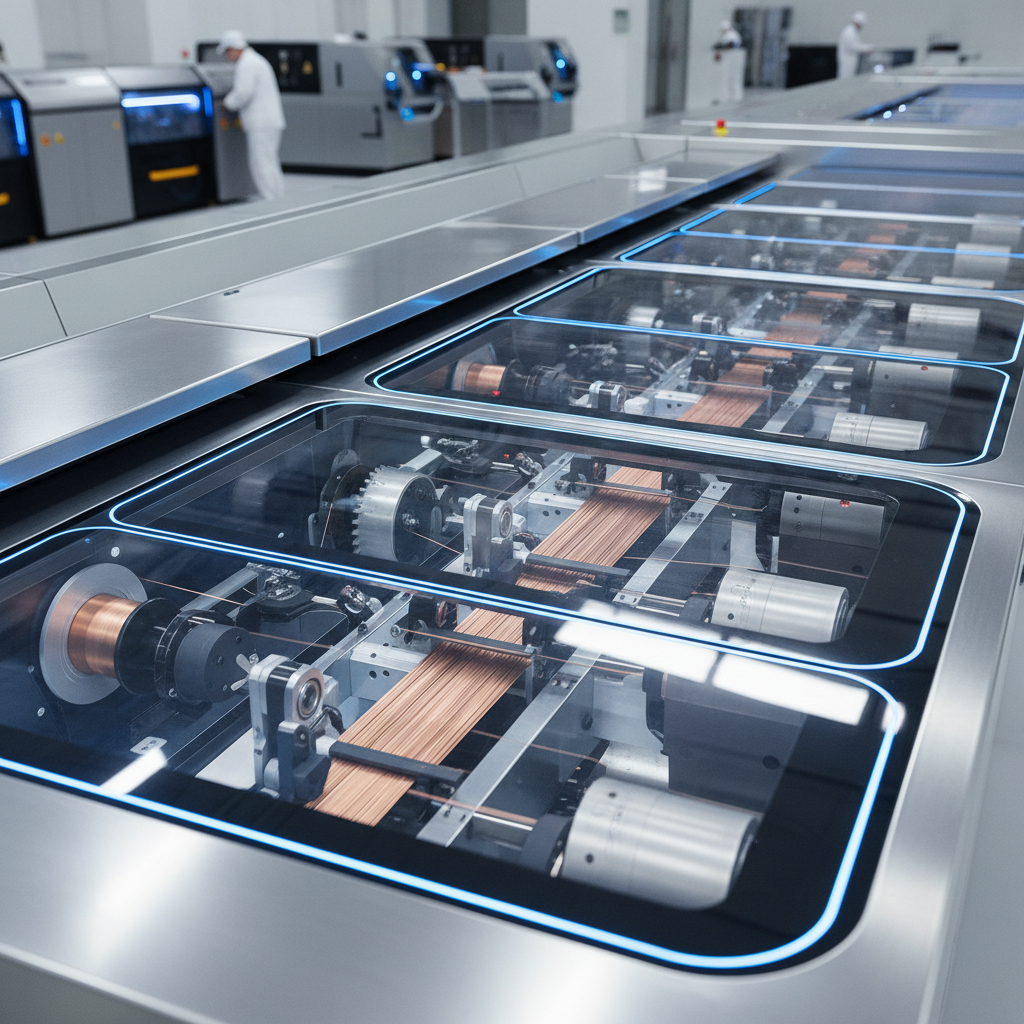

When considering a linear coil winding machine, several key features should be prioritized for optimal automation and efficiency. For instance, advancements like wire tensioners and wire guides significantly enhance the winding process. These innovations allow for consistent tension during operation, reducing the likelihood of wire breakage and ensuring a precise winding pattern. The incorporation of a traverse mechanism further streamlines the winding process, enabling quicker transitions between winding patterns and increasing overall productivity.

In the realm of customizing machinery, recent updates have shown that CNC integration can drastically improve the functionality of traditional winding machines. The automated guitar pickup winder designed for a senior project exemplifies this shift. By automating intricate tasks, such as maintaining wire tension and alignment, users can achieve a higher degree of precision in their winding applications. As suppliers continue to focus on enhancing the accuracy and reliability of their machining equipment, the benefits of these features are becoming increasingly evident, making it crucial for buyers to consider these attributes when selecting a linear coil winding machine.

Comparative Analysis of the 2025 Top Linear Coil Winding Machines

In the evolving landscape of industrial automation, the year 2025 is poised to mark a significant leap in manufacturing technologies, particularly in linear coil winding machines. These machines are integral to producing high-performance motors and transformers, and their efficiency directly influences the capabilities of various applications, including humanoid robotics. According to industry reports, the market for linear coil winding machines is anticipated to grow by 15% annually, driven by advancements in automation and increasing demand for precision components.

When evaluating the top linear coil winding machines for 2025, key features such as automation integration, precision control systems, and energy efficiency should be on your checklist. Notably, machines that incorporate advanced algorithms for real-time monitoring can vastly enhance production effectiveness. Additionally, the trend toward lightweight structure optimization, as highlighted by recent multiphysics coupling analyses, suggests that future machines will not only perform better but also contribute to sustainability efforts in manufacturing.

Tips: Always consider your production volume when selecting a machine; a higher throughput model might be advantageous. Additionally, look for manufacturers that offer robust after-sales support and training to fully leverage your investment. Finally, ensure that any machine you consider aligns with your long-term technological roadmap to optimize future upgrades and scalability.

Maintenance Tips for Longevity of Coil Winding Equipment

Proper maintenance of coil winding equipment is essential to ensure its longevity and optimal performance. Regular inspection of key components, such as the winding heads and tension controls, helps identify wear and tear before they lead to significant issues. Cleaning the machine after each use prevents dust and debris from accumulating, which can cause overheating and hinder the machine's efficiency. Additionally, lubricating moving parts according to the manufacturer’s guidelines can help minimize friction and increase durability.

Operators should also establish a routine schedule for more comprehensive maintenance checks. This includes tightening loose bolts, checking electrical connections, and testing the machine’s calibration. Keeping a log of maintenance activities not only helps track the machine's condition over time but also aids in planning for future repairs or replacements. By prioritizing maintenance, users can significantly extend the lifespan of their coil winding machines and ensure consistent production quality.

Related Posts

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

2025 Top 5 Used Coil Winding Machines You Need for Your Business

-

Revolutionizing Efficiency How Motor Winding Automatic Machines Transform Manufacturing

-

How to Choose the Best Motor Coil Winding Machine for Your Needs in 2025

-

What is Automated Machine Learning Its Impact on Industry Growth and Efficiency

-

5 Essential Tips for Choosing the Right Wire Winding Machine: Boost Efficiency by 30%