2025 Top Spindle Winding Machine Innovations and Buying Guide

In recent years, the spindle winding machine industry has witnessed remarkable advancements, driven by the increasing demand for precision and efficiency in manufacturing processes. According to a report by MarketsandMarkets, the global market for winding machines is projected to grow from USD 3.5 billion in 2020 to USD 5.2 billion by 2025, at a compound annual growth rate (CAGR) of 8.1%. This significant growth reflects the escalating need for automated solutions in various sectors, including automotive, aerospace, and renewable energy, where spindle winding machines play a critical role in producing high-quality components.

Innovations in spindle winding technology have introduced features such as enhanced automation, improved energy efficiency, and sophisticated control systems, catering to the diverse requirements of modern manufacturing. As businesses strive to optimize production capabilities and minimize waste, the adoption of advanced spindle winding machines becomes imperative. This buying guide outlines the essential innovations to look for in 2025, providing insights into the latest trends and technologies that can elevate operational efficiency. By understanding these advancements, manufacturers can make informed decisions and invest in the right equipment to stay competitive in a fast-evolving market.

Overview of Spindle Winding Machines and Their Applications

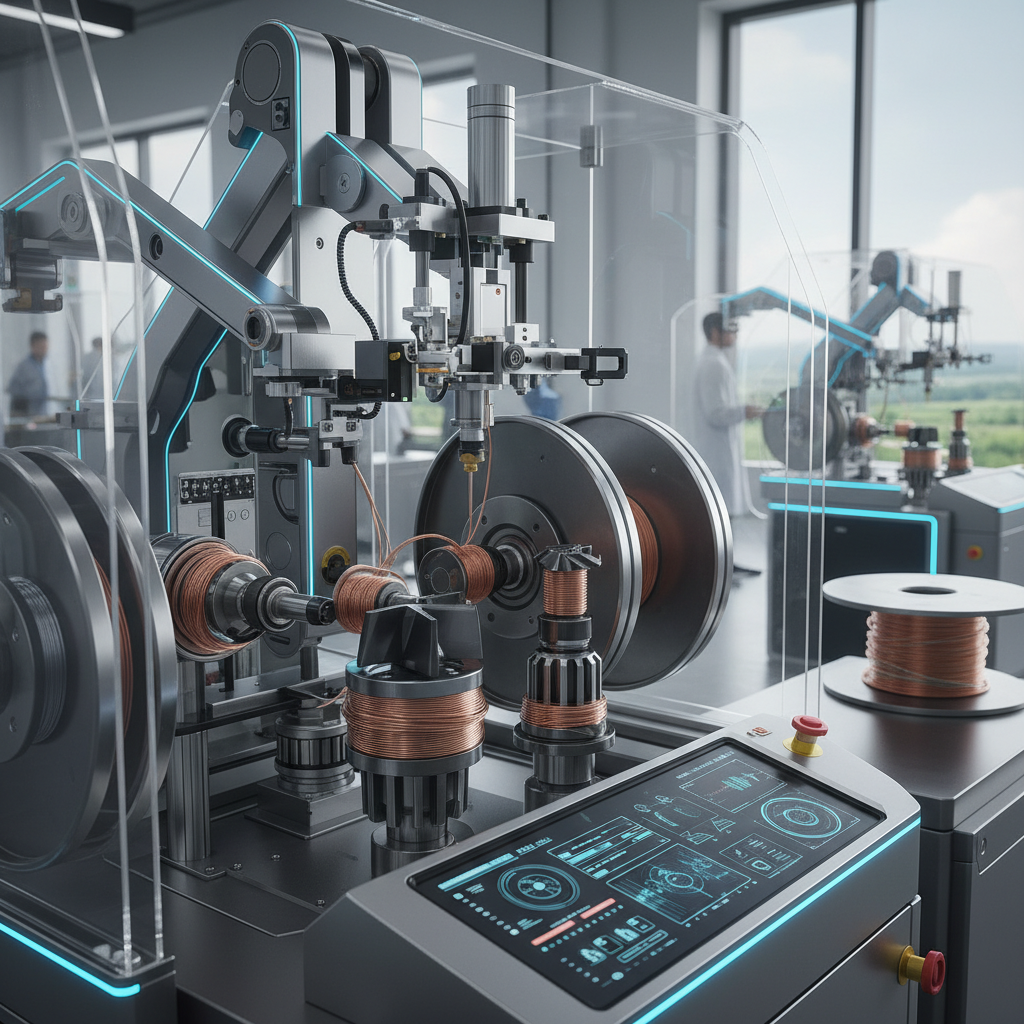

Spindle winding machines play a crucial role in modern textile manufacturing, particularly in the production of yarn and fibers. These machines are designed to efficiently wind yarn onto spools or cones, ensuring uniform tension and maximizing production efficiency. The latest innovations in spindle winding technology have significantly enhanced the capabilities of these machines, allowing for the production of high-quality yarns from both staple and man-made fibers. The focus on automation and precision has not only improved output but also reduced energy consumption and operational costs.

Recent advancements in the industry highlight the importance of energy-efficient solutions and the integration of digital technologies. Machines equipped with independent suction systems can achieve impressive energy savings while maintaining optimal performance. Furthermore, with the rise of Industry 4.0, manufacturers are increasingly adopting digital platforms to streamline operations and enhance control over spinning processes. These trends indicate a robust future for spindle winding machines as they continue to adapt to the evolving needs of the textile sector, ensuring high-quality production and sustainability in manufacturing practices.

Key Innovations in Spindle Winding Technology for 2025

As we look ahead to 2025, the spindle winding machine industry is witnessing transformative innovations that are set to redefine manufacturing processes. Key advancements include the integration of IoT (Internet of Things) technology, allowing for real-time monitoring and data analytics. According to a recent report by MarketsandMarkets, the IoT in manufacturing market is expected to grow from $41 billion in 2020 to over $100 billion by 2025, underscoring the increasing importance of connectivity in enhancing operational efficiency.

Another significant innovation is the adoption of advanced automation through AI-driven systems. These systems can optimize winding processes by analyzing variable factors such as tension and speed, which can lead to a reduction in waste and increased precision. In fact, a study by McKinsey estimates that AI applications in manufacturing can lead to productivity gains of up to 30%. This level of innovation not only improves the quality of the finished products but also positions manufacturers to respond swiftly to market demands.

Furthermore, the development of eco-friendly materials and processes is gaining traction. With sustainability becoming a pivotal concern for manufacturers, the incorporation of biodegradable materials in spindle winding machines is on the rise. According to the National Association of Manufacturers, 73% of manufacturers are actively seeking sustainable practices, illustrating a clear shift towards greener production methods in the industry.

2025 Spindle Winding Technology Innovations

This chart illustrates the key technological innovations in spindle winding machines anticipated for 2025, highlighting their performance impact across various parameters.

Factors to Consider When Buying a Spindle Winding Machine

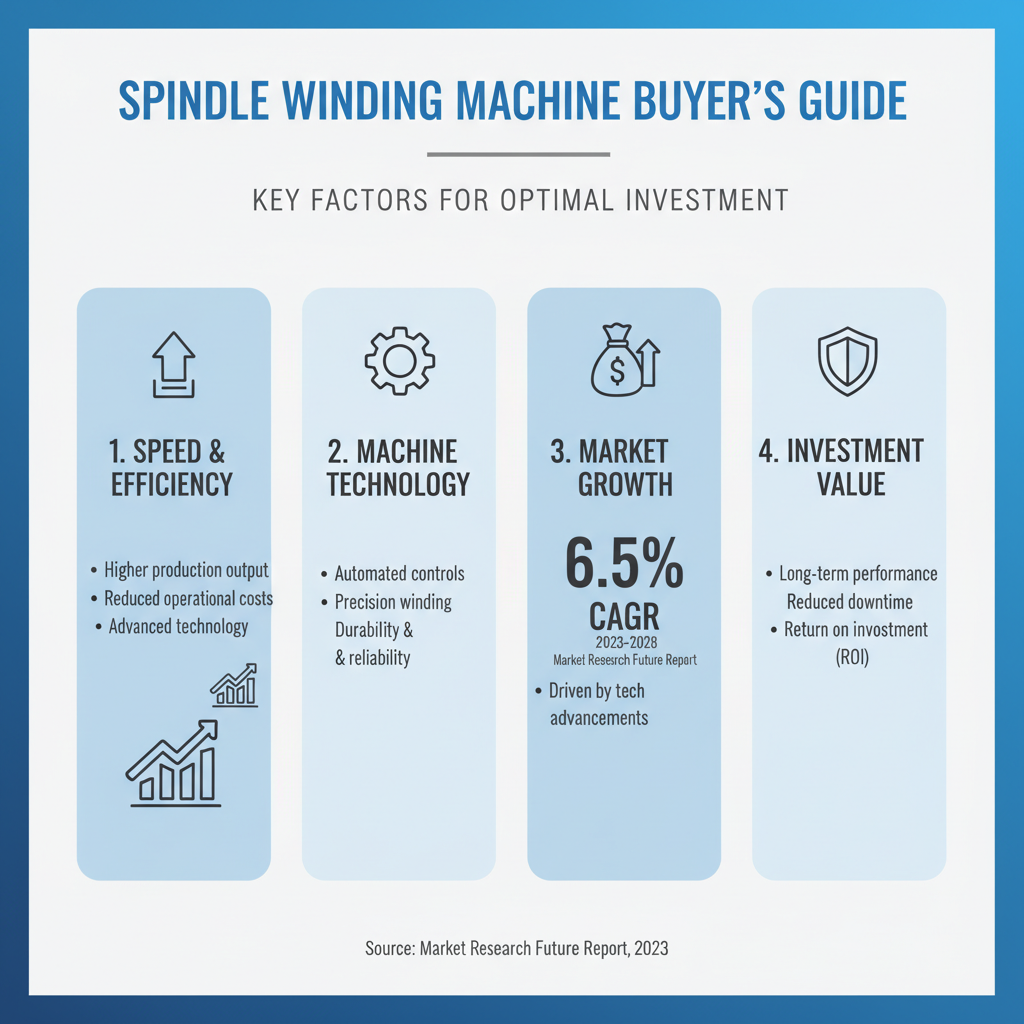

When considering the purchase of a spindle winding machine, it's essential to evaluate several critical factors to ensure optimal performance and investment value. One of the foremost aspects is the machine's speed and efficiency. According to a recent report by Market Research Future, the spindle winding machine market is projected to grow at a CAGR of 6.5% from 2023 to 2028. This growth is largely driven by advancements in machine technology that enhance production speed, thereby reducing operational costs for manufacturers.

Another significant factor is the machine's compatibility with various materials and winding techniques. As industries increasingly diversify in their product offerings, versatility becomes paramount. A machine that can handle a wide range of wire types and winding configurations not only increases production flexibility but also improves overall efficiency. Additionally, maintenance requirements and downtime should be considered, as ease of maintenance directly impacts overall productivity. According to Statista, companies lose about 5% of annual revenue due to unplanned downtime, highlighting the importance of selecting machines designed with reliable performance and straightforward maintenance in mind.

Comparative Analysis of Leading Spindle Winding Brands

As the demand for sustainable and efficient manufacturing processes grows, the spindle winding machine market is witnessing significant innovations. Leading brands are focusing on enhancing productivity while reducing energy consumption, which is increasingly crucial for environmentally conscious consumers. The latest advancements, such as the Autoconer 6, exemplify this trend by offering features that optimize operational efficiency and lower costs for manufacturers.

A comparative analysis of top spindle winding brands reveals their distinctive approaches to meeting consumer demands. While some emphasize the integration of advanced technology to streamline production, others highlight energy-efficient designs that align with the growing need for sustainable practices. As half of consumers prioritize healthy and sustainable eating, similar expectations are emerging in the textile manufacturing sector, where the focus on eco-friendly practices is becoming a standard. Understanding these innovations and strategies will be essential for businesses aiming to stay competitive in this evolving landscape.

2025 Top Spindle Winding Machine Innovations and Buying Guide - Comparative Analysis of Leading Spindle Winding Brands

| Feature | Model A | Model B | Model C | Model D |

|---|---|---|---|---|

| Max Speed (RPM) | 7000 | 8000 | 7500 | 6800 |

| Power Consumption (W) | 1500 | 1400 | 1600 | 1550 |

| Weight (kg) | 300 | 350 | 320 | 310 |

| Automatic Tension Control | Yes | No | Yes | Yes |

| User Interface | Touchscreen | Button | Touchscreen | Button |

| Warranty (Years) | 2 | 3 | 2 | 4 |

Future Trends in Spindle Winding Machine Development and Usage

The future of spindle winding machines is poised for remarkable advancements that align with the rising demand for efficiency and precision in manufacturing. As industries adopt smart technologies, spindle winding machines will increasingly incorporate automation and artificial intelligence, enhancing operational productivity. Innovations such as real-time monitoring systems will enable predictive maintenance, significantly reducing downtime and operational costs. These technologies are expected to facilitate a more intuitive user experience, allowing operators to achieve complex winding patterns with minimal manual intervention.

Additionally, the integration of eco-friendly materials and energy-efficient designs will become a paramount trend in the development of spindle winding machines. As sustainability takes center stage across various sectors, manufacturers will prioritize those features that minimize waste and lower energy consumption. Enhanced software solutions will provide users with better control over production processes, enabling the optimization of resource use. This shift toward sustainable practices not only benefits the environment but also improves the overall competitiveness of companies, positioning them favorably in a market that increasingly values green technologies.

Related Posts

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide

-

How to Choose the Best Automatic Coil Winding Machine for Your Business Needs

-

Top 5 Motor Stator Winding Machines for Efficient Coil Production

-

What is Automated Machine Learning Its Impact on Industry Growth and Efficiency

-

How to Choose the Best Motor Coil Winding Machine for Your Needs in 2025

-

5 Essential Tips for Choosing the Right Wire Winding Machine: Boost Efficiency by 30%