Top 2025 Coil Winding Machines Features Benefits and Buying Guide

The coil winding machine is a pivotal device in the manufacturing sector, particularly in industries such as electronics and automotive where precision and efficiency are paramount. According to a report by Market Research Future, the global coil winding machine market is projected to grow at a CAGR of approximately 4.5% between 2021 and 2028, driven by advancements in automation and a rising demand for electric motors and transformers. As businesses increasingly integrate smart technologies into production lines, the need for sophisticated coil winding machines capable of meeting high-volume demands while ensuring accuracy has never been more critical.

Modern coil winding machines offer a range of features that enhance usability, such as programmable logic controllers (PLCs), automatic tension control, and enhanced safety mechanisms, making them indispensable in manufacturing settings. The transition towards electric vehicles and renewable energy sources, coupled with ongoing innovations in coil technology, presents an opportunity for manufacturers to optimize their production processes. This guide will delve into the latest features and benefits of coil winding machines in 2025, equipping industry professionals with the essential knowledge to select the right equipment for their operational needs.

Key Features of Top Coil Winding Machines in 2025

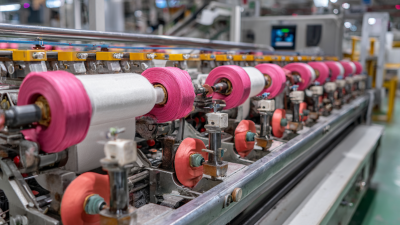

In 2025, the landscape of coil winding machines has evolved significantly, showcasing advanced features that enhance efficiency and precision in manufacturing processes. One of the key features to look for is automation capability. Modern coil winding machines now incorporate automated winding systems that reduce the need for manual intervention, improving consistency and decreasing human error. These machines are equipped with intuitive control interfaces, allowing operators to easily program winding patterns and adjust parameters on the fly, leading to optimized production cycles.

Another notable benefit is the integration of smart technology, including IoT connectivity. This development enables real-time monitoring and data analysis of winding operations, facilitating predictive maintenance and minimizing downtime. Additionally, the latest machines come with enhanced material handling systems, which can accommodate a wider range of wire gauges and insulation types. This flexibility is crucial for manufacturers looking to adapt to varying production demands while maintaining high quality. These features combined illustrate a significant leap forward in coil winding technology, making it essential for businesses to consider these advancements when investing in new machinery.

Benefits of Upgrading to Modern Coil Winding Technology

Upgrading to modern coil winding technology offers numerous advantages that can significantly enhance productivity and operational efficiency. According to industry reports, companies that invest in advanced coil winding machines can experience a boost in production speed by up to 40%. This improvement is attributed to the automation features present in contemporary machines that streamline the winding process, reduce labor costs, and minimize human error.

One of the standout benefits of modern coil winding machines is their ability to adapt to various winding patterns and specifications without major reconfiguration. This flexibility is essential in today's fast-paced manufacturing environment where customer demands are constantly evolving. Furthermore, data from the Manufacturing Technology Association highlights that companies utilizing upgraded technology saw a reduction in waste material by approximately 15%, contributing to sustainable practices and cost savings.

Tips: When considering a transition to modern coil winding technology, start by evaluating your production needs and the specific features that align with your operational goals. Additionally, seek feedback and case studies from industry peers who have successfully made the switch, as this can provide valuable insights into the practical benefits and potential ROI involved in upgrading your equipment.

Critical Factors to Consider When Buying Coil Winding Machines

When considering the purchase of a coil winding machine, several critical factors come into play that can significantly influence your decision. One fundamental aspect is the

machine's winding speed, which directly impacts production efficiency. According to industry reports, machines with higher winding speeds can enhance productivity by up to

30%, allowing manufacturers to meet demanding production schedules more effectively. It's essential to evaluate the specific speed requirements based on the types of coils you plan to produce.

Additionally, the versatility of the machine is crucial. A machine that can handle a variety of wire gauges and materials will offer greater flexibility, accommodating diverse project needs. Recent studies suggest that having a

multi-functional coil winding machine can reduce the need for multiple setups, saving both time and labor costs. Look for machines that come equipped with adjustable parameters for tension, pitch, and layer count to ensure they can meet changing demands.

Tips: When assessing coil winding machines, look for features that enhance user-friendliness such as intuitive controls and automation capabilities. Investing in training for your team can also maximize the benefits of a new machine, ensuring optimal operation and maintenance for longevity and sustained performance. Always consult with industry experts and review current market trends to make an informed decision that meets your production needs.

Industry Standards and Certifications for Coil Winding Equipment

When considering the purchase of coil winding machines, understanding the industry standards and certifications is crucial for ensuring quality, safety, and reliability. Key certifications such as ISO 9001 and CE mark indicate that the equipment meets international quality management standards and safety requirements, respectively. These certifications not only assure you of the machine's efficacy but also its compliance with health and environmental regulations that are essential in today’s manufacturing landscape.

Tips: Always verify the certification of the coil winding machine with third-party agencies to ensure it is not outdated or expired. Manufacturers that are transparent about their compliance with industry standards demonstrate reliability and commitment to quality.

In addition to the basic certifications, look for machines that adhere to specific industry standards relevant to your applications, such as IPC standards for electronic winding. Compliance with these benchmarks can greatly influence the performance and longevity of the machines, ultimately impacting your production efficiency.

Tips: Engage with industry experts or attend trade shows to gain insights into which certifications are essential for your specific needs. Such knowledge can steer you toward making informed purchasing decisions that align with industry best practices.

Future Trends in Coil Winding Machinery and Market Projections

The coil winding machinery market is projected for significant growth in the coming years, driven by advancements in technology and the rising demand for efficient manufacturing processes. According to a recent industry report by Research and Markets, the global coil winding machine market is anticipated to reach USD 800 million by 2025, growing at a CAGR of 5.8% from 2021. This growth is largely attributed to the increased adoption of automation in winding processes and the necessitation for precision in the production of electric motors, inductors, and transformers.

Future trends in coil winding machinery are leaning towards smarter, more integrated systems. Industrial IoT and machine learning are becoming pivotal in enhancing operational efficiency and predictive maintenance. For instance, the implementation of real-time data analytics helps manufacturers optimize winding parameters, reduce waste, and improve product quality. In addition, the move towards sustainable practices is influencing the design of equipment to minimize energy consumption during operation significantly.

Tips: When evaluating coil winding machines, consider features such as programmable controls, easy maintenance accessibility, and energy efficiency to future-proof your investment. It’s also beneficial to stay updated on regulatory changes in manufacturing practices as they may impact machine design and functionalities. Additionally, assess the warranty and service support provided, as robust after-sales service can enhance operational longevity.

Trends in Coil Winding Machines (2025 Projections)

This bar chart showcases the projected popularity of key features in coil winding machines by 2025. Automation and efficiency are expected to dominate as industry trends, reflecting the ongoing push for enhanced production capabilities.

Related Posts

-

Discover the Innovations in the Best Coil Winding Machine Technology for Efficient Production

-

2025 Top 5 Used Coil Winding Machines You Need for Your Business

-

How to Choose the Best Micro Coil Winding Machine for Your Needs

-

2025 Top 10 Linear Coil Winding Machines: Features, Benefits, and Buying Guide

-

How to Choose the Best Programmable Coil Winding Machine for Your Needs

-

What is a Coiling Machine and How Does it Work for Your Projects